Kiln firing enamel ensures even heat distribution, resulting in smooth, durable coatings with consistent color and texture. Torch firing allows for greater control and flexibility, ideal for small, detailed pieces but may produce uneven finishes due to localized heating. Choosing between kiln and torch firing depends on the complexity of the design and the desired enamel quality.

Table of Comparison

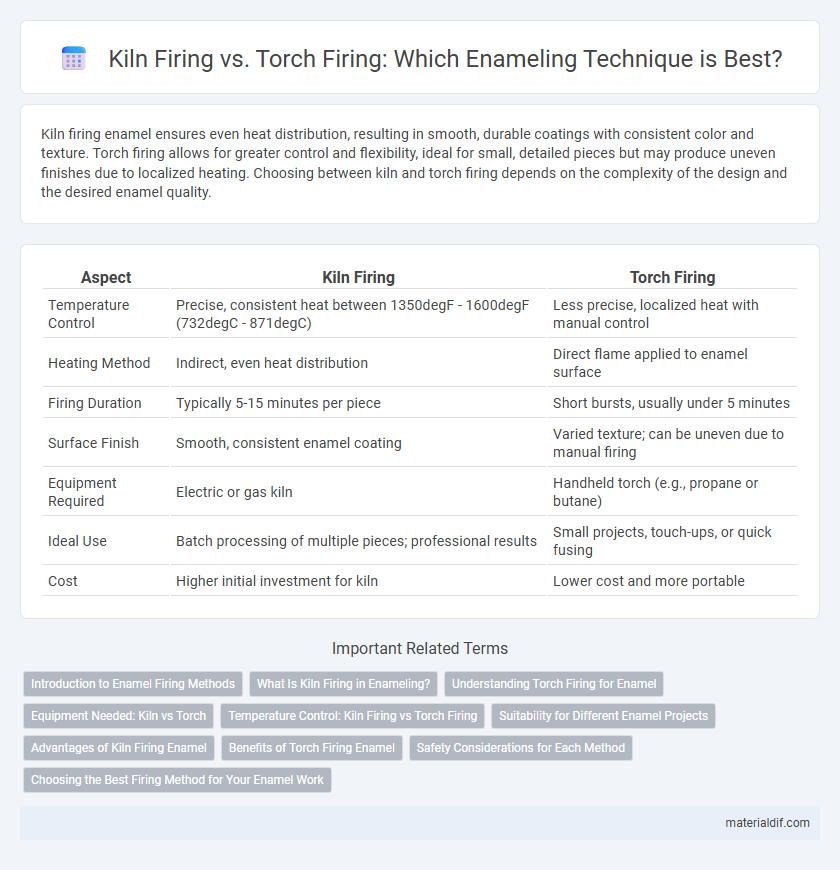

| Aspect | Kiln Firing | Torch Firing |

|---|---|---|

| Temperature Control | Precise, consistent heat between 1350degF - 1600degF (732degC - 871degC) | Less precise, localized heat with manual control |

| Heating Method | Indirect, even heat distribution | Direct flame applied to enamel surface |

| Firing Duration | Typically 5-15 minutes per piece | Short bursts, usually under 5 minutes |

| Surface Finish | Smooth, consistent enamel coating | Varied texture; can be uneven due to manual firing |

| Equipment Required | Electric or gas kiln | Handheld torch (e.g., propane or butane) |

| Ideal Use | Batch processing of multiple pieces; professional results | Small projects, touch-ups, or quick fusing |

| Cost | Higher initial investment for kiln | Lower cost and more portable |

Introduction to Enamel Firing Methods

Kiln firing and torch firing are two primary enamel firing methods used to fuse powdered glass onto metal surfaces, creating durable, colorful coatings. Kiln firing offers uniform heat distribution and precise temperature control, ideal for detailed and multiple-piece projects, typically reaching temperatures between 1400degF and 1600degF. Torch firing provides localized, rapid heating suitable for small, quick applications but requires skill to avoid uneven firing or overheating.

What Is Kiln Firing in Enameling?

Kiln firing in enameling involves heating metal coated with powdered glass in a high-temperature kiln, typically between 1400degF and 1600degF, to fuse the enamel to the metal surface. This process ensures even heat distribution, producing a smooth, durable, and glass-like finish that is resistant to chipping and cracking. Kiln firing offers precise temperature control for consistent results, making it ideal for creating detailed, high-quality enamel work on copper, silver, or gold.

Understanding Torch Firing for Enamel

Torch firing enamel involves using a handheld torch to heat the metal surface until the enamel powder melts and fuses, allowing for precise, localized application and quicker firing cycles compared to kiln firing. This technique requires careful temperature control, typically between 1400degF and 1500degF, to prevent overheating or cracking of the enamel while ensuring a smooth and durable finish. Torch firing is especially favored for small, detailed pieces or on-site work, offering flexibility and immediate results that kiln firing cannot match.

Equipment Needed: Kiln vs Torch

Kiln firing enamel requires a specialized electric or gas kiln capable of reaching temperatures between 1400degF and 1600degF for consistent and even heat distribution. Torch firing enamel uses a high-temperature handheld torch, typically a propane or butane torch, which provides localized heat suitable for smaller or detailed pieces. Kilns offer controlled environments ideal for batch processing, while torches allow for greater portability and direct heat application.

Temperature Control: Kiln Firing vs Torch Firing

Kiln firing offers precise temperature control, maintaining consistent heat levels typically between 1350degF to 1600degF, essential for evenly melting enamel powders. Torch firing, in contrast, involves direct flame application with temperatures varying rapidly, making it challenging to achieve uniform heat and resulting in potential inconsistencies in enamel fusion. Consistent kiln temperatures reduce thermal shock risks, enhancing enamel durability compared to the variable heat exposure in torch firing.

Suitability for Different Enamel Projects

Kiln firing offers precise temperature control and even heat distribution, making it ideal for complex or large enamel pieces requiring consistent melting and durability. Torch firing suits smaller, simpler projects or repairs because it provides localized heat and greater portability but may result in uneven melting and less uniform finishes. Selecting between kiln and torch firing depends on project size, detail complexity, and the desired enamel quality and finish.

Advantages of Kiln Firing Enamel

Kiln firing enamel offers precise temperature control, ensuring consistent and even heat distribution that enhances the durability and smoothness of the enamel finish. This method reduces the risk of overheating or uneven melting, resulting in fewer defects like bubbling or cracking. Kiln firing also allows for the simultaneous firing of multiple pieces, increasing production efficiency and uniform quality in enamel artworks or jewelry.

Benefits of Torch Firing Enamel

Torch firing enamel offers precise control over heat application, enabling artists to target small areas without exposing the entire piece to high temperatures, which reduces the risk of warping. It is portable and convenient, allowing for on-site enameling without the need for a bulky kiln setup. The instant heat from a torch also accelerates the firing process, shortening production time while maintaining vibrant, glass-like finishes.

Safety Considerations for Each Method

Kiln firing enamel offers controlled temperatures and consistent heat distribution, significantly reducing risks such as burns and toxic fumes compared to torch firing, which requires close proximity to an open flame and poses higher chances of accidental fires or overheating. Proper ventilation is essential in both methods, but torch firing demands more rigorous safety measures due to direct flame use and rapid temperature changes. Personal protective equipment like heat-resistant gloves and safety glasses is critical to prevent injury, with kiln firing generally providing a safer, more stable environment for enamel work.

Choosing the Best Firing Method for Your Enamel Work

Kiln firing offers consistent, controlled heat essential for achieving uniform enamel coatings and is ideal for complex or multiple pieces requiring precise temperature regulation. Torch firing provides targeted heat and greater mobility, making it suitable for small-scale or detailed enamel applications but may risk uneven heating and inconsistent results. Selecting the best firing method depends on the enamel type, project complexity, and desired finish quality to ensure optimal fusion and durability.

Kiln Firing vs Torch Firing (Enamel) Infographic

materialdif.com

materialdif.com