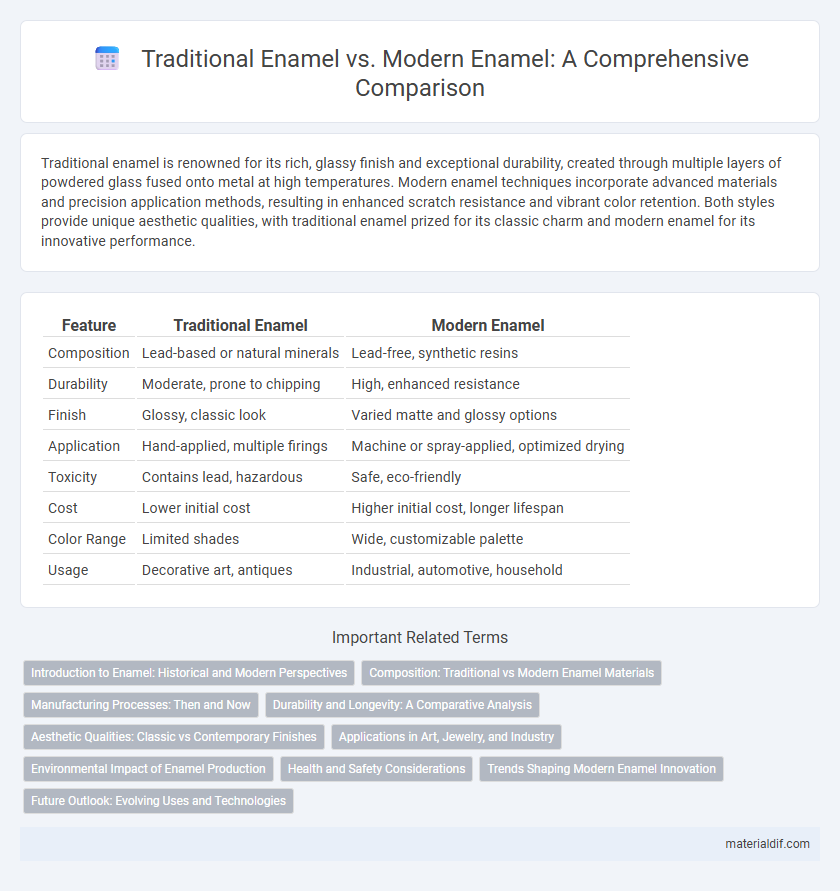

Traditional enamel is renowned for its rich, glassy finish and exceptional durability, created through multiple layers of powdered glass fused onto metal at high temperatures. Modern enamel techniques incorporate advanced materials and precision application methods, resulting in enhanced scratch resistance and vibrant color retention. Both styles provide unique aesthetic qualities, with traditional enamel prized for its classic charm and modern enamel for its innovative performance.

Table of Comparison

| Feature | Traditional Enamel | Modern Enamel |

|---|---|---|

| Composition | Lead-based or natural minerals | Lead-free, synthetic resins |

| Durability | Moderate, prone to chipping | High, enhanced resistance |

| Finish | Glossy, classic look | Varied matte and glossy options |

| Application | Hand-applied, multiple firings | Machine or spray-applied, optimized drying |

| Toxicity | Contains lead, hazardous | Safe, eco-friendly |

| Cost | Lower initial cost | Higher initial cost, longer lifespan |

| Color Range | Limited shades | Wide, customizable palette |

| Usage | Decorative art, antiques | Industrial, automotive, household |

Introduction to Enamel: Historical and Modern Perspectives

Traditional enamel, known for its use in ancient jewelry and decorative arts, is created by fusing powdered glass to metal at high temperatures, resulting in a vibrant, durable surface. Modern enamel techniques incorporate advanced materials and precision technologies that enhance durability, color variety, and application methods for industrial and artistic purposes. Both historical and contemporary enamel processes highlight the material's unique combination of beauty and resilience in design.

Composition: Traditional vs Modern Enamel Materials

Traditional enamel is primarily composed of powdered glass fused with a mix of metal oxides like silica, boron, and soda to create a durable, glossy surface. Modern enamel incorporates advanced synthetic materials including vitreous enamel combined with polymers or ceramic composites, enhancing flexibility, impact resistance, and color retention. The evolution from purely glass-based to hybrid compositions allows modern enamels to better withstand environmental stress and offer improved adhesion on diverse substrates.

Manufacturing Processes: Then and Now

Traditional enamel manufacturing involved manually applying powdered glass onto metal surfaces, followed by firing at high temperatures in wood-fired or coal-fired kilns, resulting in thicker, less uniform coatings. Modern enamel production utilizes advanced techniques such as automated spraying and controlled electric kilns to achieve precise thickness and uniformity, enhancing durability and aesthetic appeal. Innovations in material formulations and firing technologies have significantly reduced defects and improved consistency compared to historical processes.

Durability and Longevity: A Comparative Analysis

Traditional enamel, often composed of powdered glass fused at high temperatures, offers excellent hardness but can be prone to chipping and cracking over time, affecting its durability. Modern enamel formulations incorporate advanced resins and improved curing techniques, significantly enhancing resistance to wear, impact, and environmental factors. Comparative studies reveal that modern enamel coatings exhibit superior longevity, maintaining aesthetic and functional integrity far longer than traditional enamel in both domestic and industrial applications.

Aesthetic Qualities: Classic vs Contemporary Finishes

Traditional enamel offers rich, glossy finishes characterized by deep, vibrant hues and a timeless appeal rooted in handcrafted techniques. Modern enamel, by contrast, provides a wider range of matte, satin, and textured finishes achieved through advanced chemical formulations and precision coating technologies. The aesthetic qualities of classic enamel emphasize durability and warmth, while contemporary enamel focuses on sleek, customizable surfaces suited for modern interior design trends.

Applications in Art, Jewelry, and Industry

Traditional enamel techniques, such as cloisonne and champleve, are prized in art and jewelry for their vibrant colors and intricate designs, creating durable decorative surfaces. Modern enamel formulations incorporate advanced materials and firing processes to enhance hardness and chemical resistance, making them suitable for industrial applications like automotive coatings and electronic components. Both traditional and modern enamels offer unique benefits, with artisans favoring handcrafted aesthetics while industries prioritize performance and longevity.

Environmental Impact of Enamel Production

Traditional enamel production involves high-temperature kiln firing processes that consume substantial energy and emit significant CO2 levels, contributing to environmental pollution. Modern enamel techniques utilize advanced energy-efficient kilns and eco-friendly raw materials, reducing greenhouse gas emissions and minimizing waste by-products. Innovations in recycling enamel scrap and using low-VOC (volatile organic compounds) coatings further decrease the overall environmental footprint of enamel manufacturing.

Health and Safety Considerations

Traditional enamel often contains lead or other heavy metals that pose significant health risks, especially when used for food containers or cookware. Modern enamel formulations utilize non-toxic, lead-free materials that comply with strict safety regulations, minimizing exposure to hazardous substances. Advances in manufacturing techniques ensure modern enamel products offer superior durability and safety for everyday use.

Trends Shaping Modern Enamel Innovation

Modern enamel innovation is driven by trends such as enhanced durability, vibrant color options, and eco-friendly production methods, contrasting with traditional enamel's reliance on classical firing techniques and limited pigment range. Advances in nanotechnology and hybrid formulations have allowed modern enamel coatings to achieve superior resistance to chipping, UV exposure, and chemical corrosion. Sustainable sourcing of raw materials and low-energy curing processes are increasingly prioritized, aligning modern enamel products with contemporary environmental standards.

Future Outlook: Evolving Uses and Technologies

Traditional enamel, known for its durability and rich colors, continues to influence modern enamel techniques that integrate advanced materials such as nano-coatings and UV-resistant formulations. Future outlook indicates growing applications of enamel in electronics, automotive coatings, and sustainable architecture due to enhanced corrosion resistance and environmental adaptability. Emerging technologies are expected to further optimize enamel's performance by improving adhesion, flexibility, and eco-friendly production methods.

Traditional enamel vs modern enamel Infographic

materialdif.com

materialdif.com