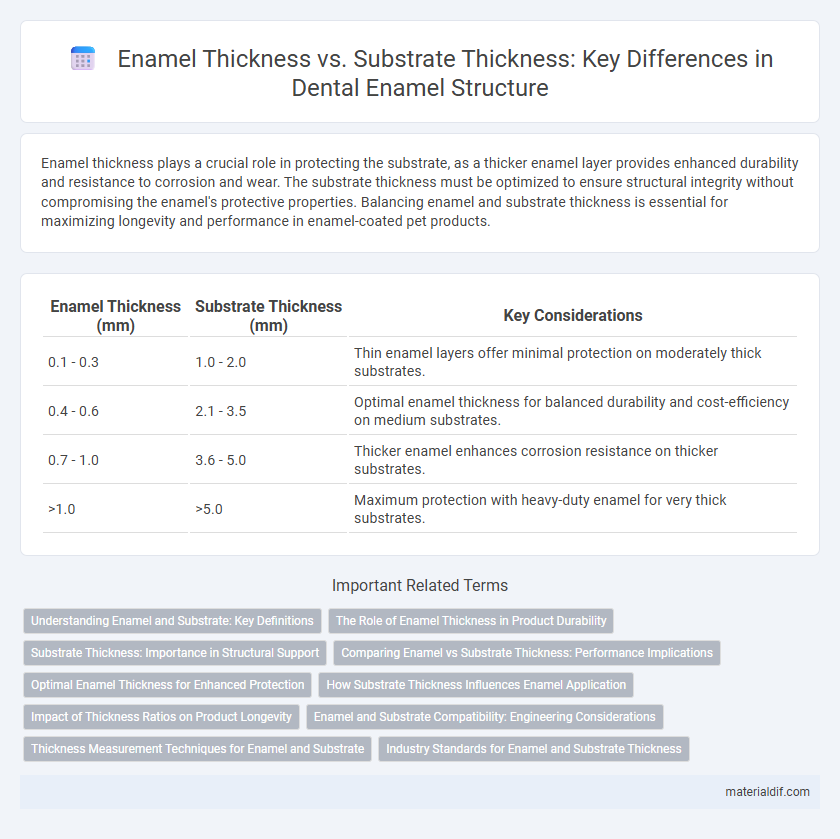

Enamel thickness plays a crucial role in protecting the substrate, as a thicker enamel layer provides enhanced durability and resistance to corrosion and wear. The substrate thickness must be optimized to ensure structural integrity without compromising the enamel's protective properties. Balancing enamel and substrate thickness is essential for maximizing longevity and performance in enamel-coated pet products.

Table of Comparison

| Enamel Thickness (mm) | Substrate Thickness (mm) | Key Considerations |

|---|---|---|

| 0.1 - 0.3 | 1.0 - 2.0 | Thin enamel layers offer minimal protection on moderately thick substrates. |

| 0.4 - 0.6 | 2.1 - 3.5 | Optimal enamel thickness for balanced durability and cost-efficiency on medium substrates. |

| 0.7 - 1.0 | 3.6 - 5.0 | Thicker enamel enhances corrosion resistance on thicker substrates. |

| >1.0 | >5.0 | Maximum protection with heavy-duty enamel for very thick substrates. |

Understanding Enamel and Substrate: Key Definitions

Enamel thickness typically ranges from 2 to 3 millimeters, providing a durable, protective outer layer that resists wear and acid erosion. Substrate thickness, often referring to the dentin or underlying material beneath enamel, varies more significantly depending on tooth anatomy and influences the overall strength and resilience of the tooth structure. Understanding the precise measurements of both enamel and substrate thickness is crucial for dental restorations, ensuring optimal bonding, longevity, and functional performance.

The Role of Enamel Thickness in Product Durability

Enamel thickness plays a crucial role in product durability by providing a protective barrier that resists chipping, scratching, and corrosion. Optimal enamel thickness must be balanced with substrate thickness to ensure structural integrity without compromising material performance. Thicker enamel layers enhance surface hardness and longevity, but excessive thickness relative to the substrate can lead to cracking or delamination under mechanical stress.

Substrate Thickness: Importance in Structural Support

Substrate thickness plays a critical role in providing structural support to enamel, directly influencing its durability and resistance to mechanical stress. A thicker substrate ensures a stable foundation, preventing enamel cracking or chipping under load. Optimal substrate thickness balances flexibility and strength, enhancing the overall performance of enamel-coated surfaces in various applications.

Comparing Enamel vs Substrate Thickness: Performance Implications

Enamel thickness significantly influences the durability and resistance to wear, often providing a protective barrier over the substrate material, which typically has a different mechanical strength. Thicker enamel layers enhance corrosion resistance and surface hardness, while the substrate thickness determines the overall structural integrity and load-bearing capacity. Balancing enamel and substrate thickness is crucial for optimizing product performance, as excessively thick enamel can crack under stress, whereas insufficient substrate thickness may lead to deformation or failure during use.

Optimal Enamel Thickness for Enhanced Protection

Optimal enamel thickness typically ranges between 2 to 3 millimeters, ensuring sufficient durability and resistance against mechanical wear and chemical erosion. Substrate thickness, such as metal or ceramic base materials, must complement enamel layers to provide structural support without compromising flexibility or causing stress fractures. Maintaining a balanced ratio between enamel and substrate thickness enhances overall protection, extending the lifespan of coated surfaces in industrial and dental applications.

How Substrate Thickness Influences Enamel Application

Substrate thickness significantly impacts enamel application by affecting the enamel's adhesion and durability. Thicker substrates provide a stable base that minimizes flexing, reducing the risk of enamel cracking or chipping. Optimal enamel thickness is adjusted according to substrate thickness to ensure uniform coverage and enhanced resistance to thermal and mechanical stresses.

Impact of Thickness Ratios on Product Longevity

Optimal enamel thickness relative to substrate thickness significantly influences product longevity by enhancing resistance to mechanical wear and chemical corrosion. A balanced enamel-to-substrate ratio prevents delamination and cracking, ensuring structural integrity over time. Excessive enamel thickness can induce internal stresses, while too thin enamel fails to provide adequate protection, reducing the lifespan of coated products.

Enamel and Substrate Compatibility: Engineering Considerations

Enamel thickness must be carefully engineered in relation to substrate thickness to prevent cracking and ensure optimal adhesion during thermal cycling. Compatibility between enamel and substrate materials involves matching coefficients of thermal expansion to reduce stress and enhance durability in applications such as cookware and industrial coatings. Precise control over enamel layer thickness supports structural integrity, improves corrosion resistance, and maintains aesthetic quality over the product's lifecycle.

Thickness Measurement Techniques for Enamel and Substrate

Accurate enamel thickness measurement utilizes techniques such as optical coherence tomography (OCT), ultrasound pulse-echo, and micro-CT scanning, providing non-destructive and precise data critical for dental diagnostics. Substrate thickness, often assessed via microhardness testing or cross-sectional imaging, influences enamel support and overall tooth integrity. Integrating digital radiography with advanced imaging algorithms enhances the correlation between enamel and substrate thickness, optimizing restorative dental treatments.

Industry Standards for Enamel and Substrate Thickness

Industry standards for enamel thickness typically range from 20 to 100 microns, ensuring optimal protection and aesthetic quality on metal substrates commonly used in cookware and industrial applications. Substrate thickness varies widely depending on the application, often falling between 0.3 mm to 2 mm for steel substrates, balancing mechanical strength and thermal conductivity. Adhering to these thickness specifications is critical for performance, durability, and coating adhesion in enamel-coated products.

Enamel thickness vs Substrate thickness Infographic

materialdif.com

materialdif.com