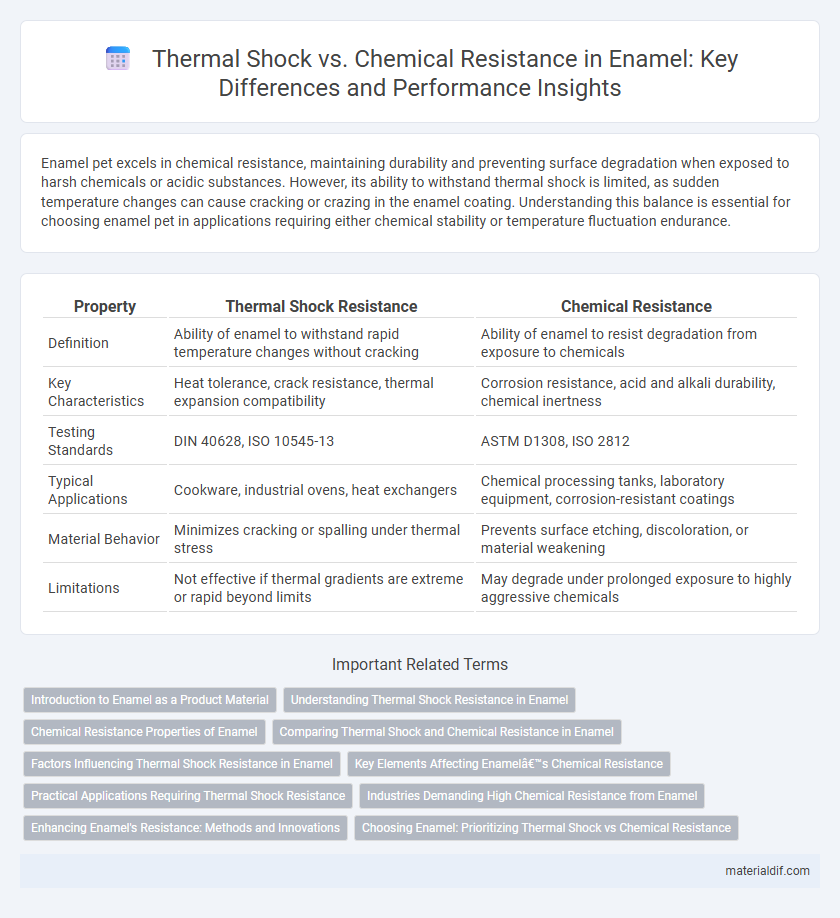

Enamel pet excels in chemical resistance, maintaining durability and preventing surface degradation when exposed to harsh chemicals or acidic substances. However, its ability to withstand thermal shock is limited, as sudden temperature changes can cause cracking or crazing in the enamel coating. Understanding this balance is essential for choosing enamel pet in applications requiring either chemical stability or temperature fluctuation endurance.

Table of Comparison

| Property | Thermal Shock Resistance | Chemical Resistance |

|---|---|---|

| Definition | Ability of enamel to withstand rapid temperature changes without cracking | Ability of enamel to resist degradation from exposure to chemicals |

| Key Characteristics | Heat tolerance, crack resistance, thermal expansion compatibility | Corrosion resistance, acid and alkali durability, chemical inertness |

| Testing Standards | DIN 40628, ISO 10545-13 | ASTM D1308, ISO 2812 |

| Typical Applications | Cookware, industrial ovens, heat exchangers | Chemical processing tanks, laboratory equipment, corrosion-resistant coatings |

| Material Behavior | Minimizes cracking or spalling under thermal stress | Prevents surface etching, discoloration, or material weakening |

| Limitations | Not effective if thermal gradients are extreme or rapid beyond limits | May degrade under prolonged exposure to highly aggressive chemicals |

Introduction to Enamel as a Product Material

Enamel exhibits excellent chemical resistance due to its glass-like coating, which protects underlying materials from corrosion and staining caused by acids, alkalis, and solvents. While enamel demonstrates moderate thermal shock resistance, rapid temperature changes can cause cracking or crazing due to its brittle nature. Selecting enamel as a product material requires balancing its superior chemical durability with careful management of thermal stresses to ensure longevity.

Understanding Thermal Shock Resistance in Enamel

Thermal shock resistance in enamel refers to its ability to withstand rapid temperature changes without cracking or damage, which is critical for applications involving extreme heat fluctuations such as cookware or industrial equipment. This resistance depends on the enamel's composition, thickness, and the compatibility between the enamel coating and the substrate material. Chemical resistance, while important, primarily relates to the enamel's durability against corrosive substances rather than temperature-induced stress, making thermal shock resistance a distinct and vital property for maintaining enamel integrity under thermal cycling conditions.

Chemical Resistance Properties of Enamel

Enamel exhibits exceptional chemical resistance due to its dense, non-porous glassy surface, making it highly resistant to acids, alkalis, and solvents commonly encountered in industrial and household applications. This chemical stability ensures long-term durability and protection against corrosion and staining, preserving both aesthetic and functional qualities. Its ability to withstand harsh chemical exposure without degradation makes enamel a preferred coating material for cookware, laboratory equipment, and chemical storage tanks.

Comparing Thermal Shock and Chemical Resistance in Enamel

Enamel exhibits superior chemical resistance due to its non-porous, glassy surface that prevents corrosion and chemical degradation. Thermal shock resistance in enamel varies depending on its formulation and thickness, with some enamels capable of withstanding rapid temperature changes without cracking. Comparing both, chemical resistance remains a consistent advantage for enamel, while thermal shock resistance can be more variable and sensitive to specific application conditions.

Factors Influencing Thermal Shock Resistance in Enamel

Thermal shock resistance in enamel is primarily influenced by factors such as the coefficient of thermal expansion, substrate compatibility, and enamel thickness. Variations in thermal expansion between the enamel coating and underlying metal can cause stress, leading to cracking or delamination. Proper formulation and controlled cooling rates enhance enamel's ability to withstand rapid temperature changes, optimizing durability against thermal shock.

Key Elements Affecting Enamel’s Chemical Resistance

Enamel's chemical resistance is primarily influenced by its glassy matrix composition, firing temperature, and the presence of specific oxides like silica and alumina that enhance durability against corrosive agents. Thermal shock resistance depends on the enamel's coefficient of thermal expansion and the compatibility between the enamel layer and substrate material, minimizing cracking under rapid temperature changes. Optimizing key elements such as flux content and balance of alkaline earth metals ensures enhanced resistance to chemical degradation while maintaining structural integrity under thermal stress.

Practical Applications Requiring Thermal Shock Resistance

Enamel coatings used in high-temperature environments demonstrate exceptional thermal shock resistance, making them ideal for applications in heat exchangers, cookware, and furnace linings where rapid temperature changes occur. Their ability to withstand sudden thermal fluctuations prevents cracking and extends the lifespan of industrial equipment exposed to repeated heating and cooling cycles. Thermal shock resistance in enamel is critical for maintaining structural integrity and performance in sectors such as metallurgy, chemical processing, and household appliance manufacturing.

Industries Demanding High Chemical Resistance from Enamel

Enamel's superior chemical resistance makes it indispensable in industries such as chemical processing, pharmaceuticals, and food manufacturing, where exposure to corrosive substances is frequent. While thermal shock resistance is vital for applications involving rapid temperature changes, sectors requiring longevity against harsh chemicals prioritize enamel formulations with enhanced acid and alkali resistance. These industries benefit from enamel coatings that protect equipment surfaces, ensuring durability and compliance with strict safety standards.

Enhancing Enamel's Resistance: Methods and Innovations

Enhancing enamel's resistance to thermal shock involves optimizing its composition by incorporating alumina and zirconia, which improve toughness and reduce crack propagation. Innovations in chemical resistance focus on surface treatments such as fluoropolymer coatings and nanocomposite layers that create impermeable barriers against corrosive agents. Advanced curing techniques like rapid thermal processing enhance enamel adhesion and durability, resulting in a more resilient and long-lasting protective finish.

Choosing Enamel: Prioritizing Thermal Shock vs Chemical Resistance

Choosing enamel for applications requiring durability involves balancing thermal shock resistance and chemical resistance. Enamels with high thermal shock resistance, such as those formulated with borosilicate glass, withstand rapid temperature changes without cracking. In contrast, chemically resistant enamels, often containing fluoropolymer coatings, provide superior protection against acids, alkalis, and solvents but may have lower tolerance to sudden thermal stress.

Thermal shock vs Chemical resistance Infographic

materialdif.com

materialdif.com