Stenciling enamel involves applying enamel paste through a stencil to create precise and detailed patterns, offering vibrant colors and sharp designs perfect for decorative accents. Cloisonne enamel uses thin metal wires to form compartments that are filled with enamel, resulting in intricate, raised patterns with a rich texture and dimensionality. Both techniques showcase enamel's versatility but differ in texture, complexity, and the tactile experience they deliver.

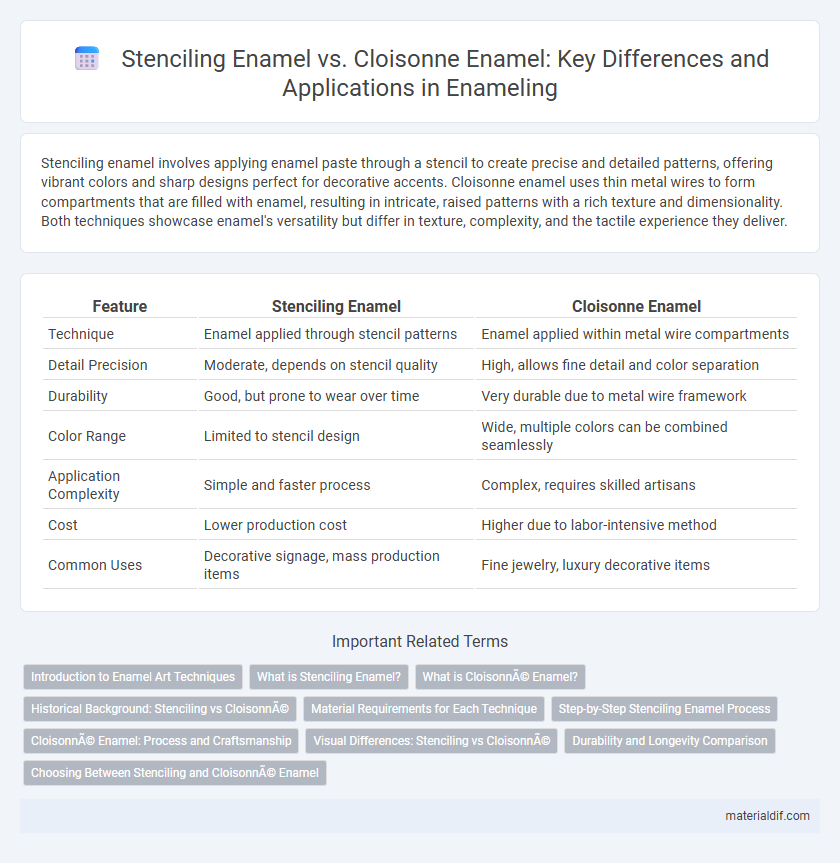

Table of Comparison

| Feature | Stenciling Enamel | Cloisonne Enamel |

|---|---|---|

| Technique | Enamel applied through stencil patterns | Enamel applied within metal wire compartments |

| Detail Precision | Moderate, depends on stencil quality | High, allows fine detail and color separation |

| Durability | Good, but prone to wear over time | Very durable due to metal wire framework |

| Color Range | Limited to stencil design | Wide, multiple colors can be combined seamlessly |

| Application Complexity | Simple and faster process | Complex, requires skilled artisans |

| Cost | Lower production cost | Higher due to labor-intensive method |

| Common Uses | Decorative signage, mass production items | Fine jewelry, luxury decorative items |

Introduction to Enamel Art Techniques

Stenciling enamel involves applying enamel paste through a carefully designed stencil, resulting in precise, repeatable patterns with sharp edges, ideal for mass production and graphic designs. Cloisonne enamel requires crafting delicate metal partitions (cloisons) to create compartments filled with enamel, allowing for intricate, multi-colored, and dimensional designs that highlight artisanal craftsmanship. Both techniques are fundamental in enamel art, offering unique textures and aesthetics suited for different artistic and commercial applications.

What is Stenciling Enamel?

Stenciling enamel is a decorative technique where enamel powder or paste is applied through a stencil onto a metal surface before being fired at high temperatures to create precise and intricate designs. Unlike cloisonne enamel, which involves filling metal compartments (cloisons) with enamel, stenciling enamel relies on a template to achieve detailed patterns without raised metal borders. This method allows for sharp, consistent imagery, often used in fine jewelry and decorative objects for its ability to produce vivid, graphic motifs.

What is Cloisonné Enamel?

Cloisonne enamel is a decorative art technique where thin metal wires are used to create compartments on a metal surface, which are then filled with vibrant enamel powders and fired to create a smooth, glassy finish. This method contrasts with stenciling enamel, which applies enamel through a cut-out design directly onto the surface without the raised metal borders. Cloisonne enamel is prized for its intricate detail, durability, and rich color depth achieved through multiple firings.

Historical Background: Stenciling vs Cloisonné

Stenciling enamel dates back to ancient civilizations where artisans used cut-out templates to apply colorful powdered glass designs before firing, allowing for rapid production of intricate patterns on jewelry and decorative objects. Cloisonne enamel originated in the Byzantine Empire and gained prominence in China during the Ming Dynasty, characterized by thin metal wires forming compartments (cloisons) filled with enamel, showcasing exquisite craftsmanship and complex imagery. Both techniques reflect distinct cultural heritages and technological advancements, with stenciling emphasizing efficiency and cloisonne exemplifying detailed, handcrafted artistry.

Material Requirements for Each Technique

Stenciling enamel requires finely ground enamel powders and a smooth base metal such as copper or silver to allow precise application through stencil patterns. Cloisonne enamel demands thin metal strips, typically gold or brass, soldered onto a metal base to create compartments that hold different enamel colors during firing. Both techniques necessitate careful selection of enamel types that can withstand multiple firings without cracking or discoloration, but cloisonne's compartmentalized structure requires more durable enamel consistency to prevent color blending.

Step-by-Step Stenciling Enamel Process

The Stenciling Enamel process begins by applying a fine metal or paper stencil onto a prepared metal surface, typically copper or silver, to create precise patterns. Enamel powders are then carefully sifted or brushed over the stencil openings before firing in a kiln at temperatures ranging from 750 to 850 degrees Celsius, causing the powder to melt and fuse seamlessly to the metal substrate. Repeated layers with intermittent firings enhance color depth and durability, distinguishing Stenciling Enamel with its sharp, graphic designs compared to the raised partitions of Cloisonne Enamel.

Cloisonné Enamel: Process and Craftsmanship

Cloisonne enamel involves creating intricate designs by soldering fine metal wires onto a metal base to form compartments, which are then meticulously filled with powdered glass enamel and fired at high temperatures to fuse the material. This traditional technique demands exceptional craftsmanship, precision, and patience, resulting in rich, colorful, and durable decorative art. The complexity of cloisonne distinguishes it from simpler stenciling enamel methods, showcasing superior texture and depth in jewelry, vases, and ornamental objects.

Visual Differences: Stenciling vs Cloisonné

Stenciling enamel creates sharp, flat, and graphic patterns with precise edges and uniform color application, resulting in a smooth surface finish. Cloisonne enamel features raised metal partitions (cloisons) that form distinct, segmented compartments filled with vibrant enamel, producing a textured and dimensional effect. The visual contrast lies in stenciling's planar, stencil-like imagery versus cloisonne's intricate metal borders enclosing varied enamel hues.

Durability and Longevity Comparison

Stenciling enamel, applied through a delicate layering process, tends to have moderate durability but is more susceptible to chipping and wear over time compared to cloisonne enamel. Cloisonne enamel features enamel applied within raised metal compartments, creating a thicker, more robust surface that offers superior scratch resistance and longevity. This structural difference results in cloisonne enamel often maintaining its vibrant colors and intricate designs for decades, outperforming the relatively fragile stenciling enamel in terms of durability and lifespan.

Choosing Between Stenciling and Cloisonné Enamel

Choosing between stenciling enamel and cloisonne enamel depends on the desired design complexity and texture. Stenciling enamel allows for precise, flat patterns with vibrant colors ideal for mass production, while cloisonne enamel creates intricate, raised designs separated by metal wires, offering a more luxurious and durable finish. Consider the project's budget, durability needs, and artistic detail to determine the most suitable enamel technique.

Stenciling Enamel vs Cloisonné Enamel Infographic

materialdif.com

materialdif.com