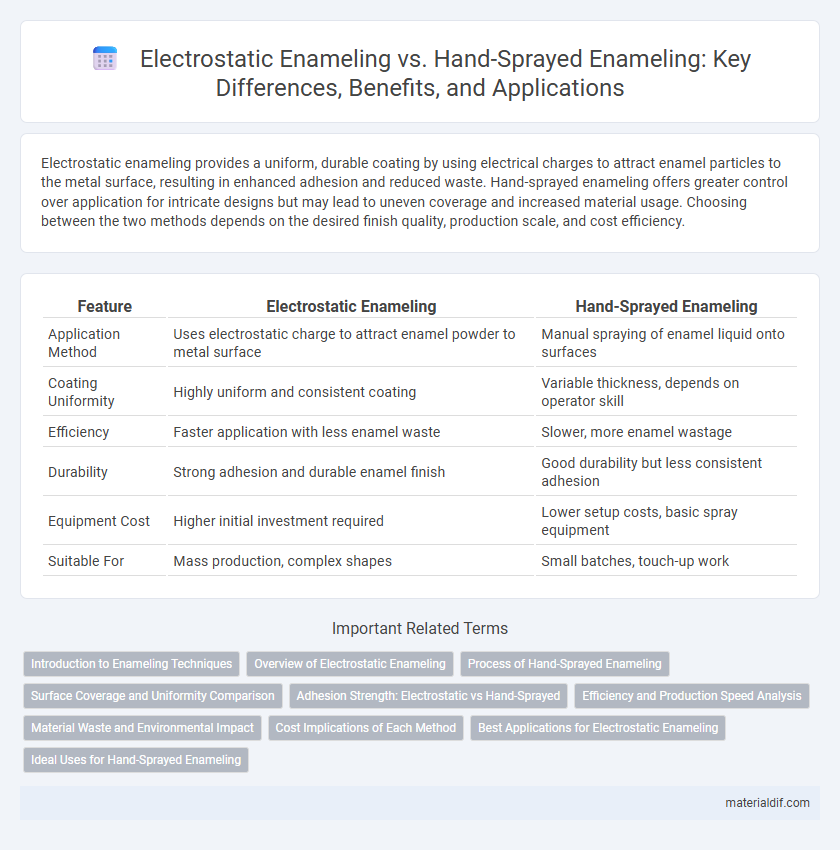

Electrostatic enameling provides a uniform, durable coating by using electrical charges to attract enamel particles to the metal surface, resulting in enhanced adhesion and reduced waste. Hand-sprayed enameling offers greater control over application for intricate designs but may lead to uneven coverage and increased material usage. Choosing between the two methods depends on the desired finish quality, production scale, and cost efficiency.

Table of Comparison

| Feature | Electrostatic Enameling | Hand-Sprayed Enameling |

|---|---|---|

| Application Method | Uses electrostatic charge to attract enamel powder to metal surface | Manual spraying of enamel liquid onto surfaces |

| Coating Uniformity | Highly uniform and consistent coating | Variable thickness, depends on operator skill |

| Efficiency | Faster application with less enamel waste | Slower, more enamel wastage |

| Durability | Strong adhesion and durable enamel finish | Good durability but less consistent adhesion |

| Equipment Cost | Higher initial investment required | Lower setup costs, basic spray equipment |

| Suitable For | Mass production, complex shapes | Small batches, touch-up work |

Introduction to Enameling Techniques

Electrostatic enameling utilizes charged particles to achieve a uniform and durable coating on metal surfaces, enhancing corrosion resistance and aesthetic appeal. Hand-sprayed enameling relies on manual application, offering greater control over design details but often resulting in less consistent coverage. Both techniques are essential in manufacturing and artistic industries, with electrostatic enameling favored for industrial-scale efficiency and hand-sprayed enameling preferred for custom or intricate finishes.

Overview of Electrostatic Enameling

Electrostatic enameling utilizes charged particles to ensure even coating application on metal surfaces, resulting in enhanced durability and uniform thickness. This process reduces overspray waste and improves adhesion compared to traditional hand-sprayed enameling. Industrial manufacturers favor electrostatic enameling for consistent quality and cost efficiency in high-volume production.

Process of Hand-Sprayed Enameling

Hand-sprayed enameling involves manually applying liquid enamel onto a surface using a spray gun, allowing precise control over thickness and coverage. This process is ideal for intricate designs and small-scale applications where detail and customization are critical. The technique requires skilled operators to ensure uniform coating and minimize overspray, resulting in a smooth, high-quality finish.

Surface Coverage and Uniformity Comparison

Electrostatic enameling provides superior surface coverage and uniformity compared to hand-sprayed enameling by using charged particles that evenly adhere to metal surfaces, minimizing overspray and thin spots. Hand-sprayed enameling often results in inconsistent coating thickness and patchy coverage due to manual application variability. The electrostatic process enhances durability and aesthetic appeal by creating a smooth, continuous enamel layer across complex geometries.

Adhesion Strength: Electrostatic vs Hand-Sprayed

Electrostatic enameling delivers superior adhesion strength by using electrical charges to attract enamel particles uniformly to the metal surface, resulting in a more consistent and durable coating. Hand-sprayed enameling often suffers from uneven layer thickness and weaker bonding due to manual application variability. The enhanced bonding of electrostatic enameling improves resistance to chipping, corrosion, and wear compared to traditional hand-sprayed methods.

Efficiency and Production Speed Analysis

Electrostatic enameling offers higher efficiency and faster production speeds compared to hand-sprayed enameling, due to its ability to uniformly coat complex surfaces with minimal overspray and material waste. This automated process reduces labor costs and ensures consistent enamel thickness, enhancing overall throughput in industrial applications. Hand-sprayed enameling, although flexible for small batches and detailed work, typically results in slower production and higher variability in coating quality.

Material Waste and Environmental Impact

Electrostatic enameling significantly reduces material waste by using charged particles that uniformly adhere to surfaces, minimizing overspray and excess enamel. Hand-sprayed enameling typically results in higher material waste due to uneven application and excess enamel falling off the target surface. The environmental impact of electrostatic enameling is lower, as it decreases volatile organic compound emissions and resource consumption compared to traditional hand-spraying methods.

Cost Implications of Each Method

Electrostatic enameling reduces paint waste by up to 30%, resulting in lower material costs compared to hand-sprayed enameling, which often leads to higher overspray and increased paint usage. The initial investment for electrostatic equipment ranges from $15,000 to $50,000 but offers long-term savings through faster application and less labor intensive processes. Hand-sprayed enameling has minimal upfront costs but incurs higher ongoing labor and material expenses, making it less cost-effective for large-scale production.

Best Applications for Electrostatic Enameling

Electrostatic enameling excels in coating metal surfaces with uniform, durable finishes, making it ideal for automotive parts, appliances, and industrial equipment where precision and consistency are critical. This method offers superior paint adhesion and reduced overspray, enhancing efficiency in high-volume production environments. Its ability to evenly cover complex shapes and recessed areas positions electrostatic enameling as the best choice for applications demanding both aesthetic quality and long-lasting protection.

Ideal Uses for Hand-Sprayed Enameling

Hand-sprayed enameling is ideal for custom, small-batch, or intricate projects requiring precise control over enamel thickness and coverage. It excels in repairing or touching up existing finishes and achieving unique decorative effects on irregular surfaces. This method suits artisanal work and applications where electrostatic enameling's uniformity and speed are less critical.

Electrostatic Enameling vs Hand-Sprayed Enameling Infographic

materialdif.com

materialdif.com