Low-carbon steel is preferred for enameling due to its excellent malleability and lower risk of cracking during the firing process, allowing for a smoother, more even enamel coating. High-carbon steel, though harder and stronger, tends to be more brittle and prone to warping or fracturing under the high temperatures required for enameling, which can compromise the integrity of the enamel layer. Selecting the appropriate steel type is crucial to achieving durable, high-quality enamel finishes that resist chipping and wear.

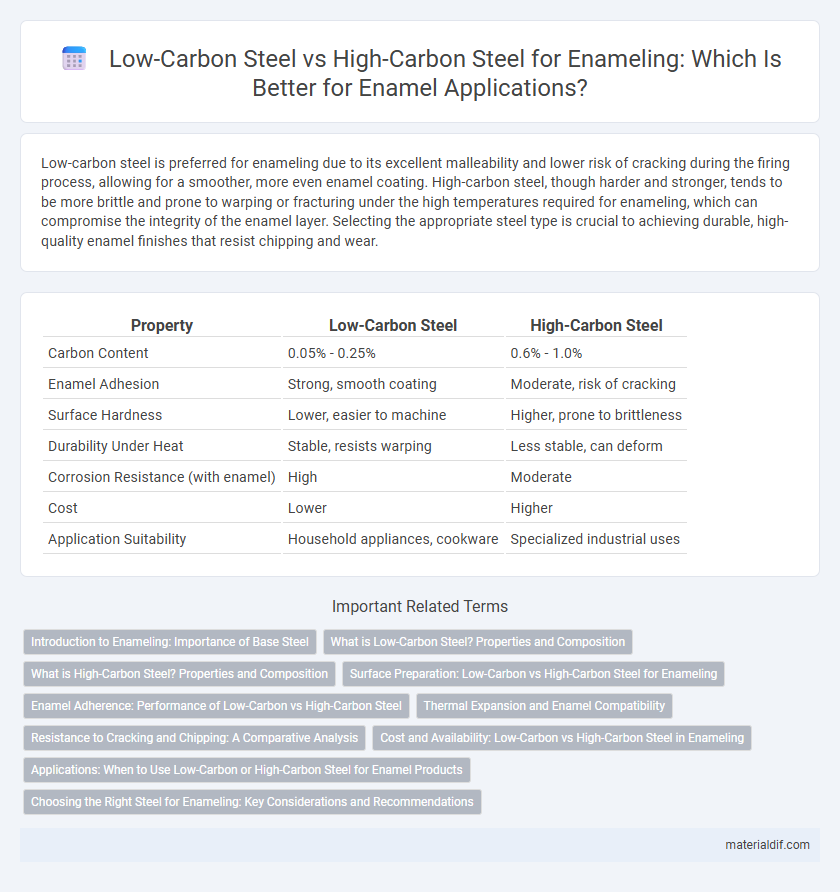

Table of Comparison

| Property | Low-Carbon Steel | High-Carbon Steel |

|---|---|---|

| Carbon Content | 0.05% - 0.25% | 0.6% - 1.0% |

| Enamel Adhesion | Strong, smooth coating | Moderate, risk of cracking |

| Surface Hardness | Lower, easier to machine | Higher, prone to brittleness |

| Durability Under Heat | Stable, resists warping | Less stable, can deform |

| Corrosion Resistance (with enamel) | High | Moderate |

| Cost | Lower | Higher |

| Application Suitability | Household appliances, cookware | Specialized industrial uses |

Introduction to Enameling: Importance of Base Steel

Low-carbon steel is preferred for enameling due to its superior weldability and reduced risk of cracking under high-temperature fusing processes. High-carbon steel, while stronger, often exhibits increased brittleness that can compromise enamel adhesion and durability during firing. Selecting the appropriate base steel directly impacts the enamel coating's longevity and resistance to chipping, making low-carbon steel the industry standard for enamel applications.

What is Low-Carbon Steel? Properties and Composition

Low-carbon steel, commonly used in enameling, contains approximately 0.05% to 0.25% carbon, making it more ductile and less brittle than high-carbon steel. Its lower carbon content results in improved weldability and better thermal conductivity, essential for achieving a smooth, defect-free enamel coating. These properties make low-carbon steel ideal for producing durable, corrosion-resistant enameled products with excellent adhesion.

What is High-Carbon Steel? Properties and Composition

High-carbon steel contains 0.6% to 1.0% carbon, giving it greater hardness and strength compared to low-carbon steel, which typically contains less than 0.3% carbon. This increased carbon content enhances its wear resistance and tensile strength, making it suitable for applications requiring durability, such as enameling surfaces exposed to frequent abrasion. The composition also includes small amounts of manganese and silicon, which improve its toughness and ability to form a strong bond with enamel coatings.

Surface Preparation: Low-Carbon vs High-Carbon Steel for Enameling

Low-carbon steel offers superior surface preparation for enameling due to its smoother texture and lower impurity content, enabling better enamel adhesion and reducing defects like blistering. High-carbon steel requires more intensive cleaning and etching processes to remove carbon residues and surface irregularities, which can compromise the enamel's durability and aesthetic quality. Proper surface treatment tailored to steel carbon content is critical for achieving optimal enamel coating performance and longevity.

Enamel Adherence: Performance of Low-Carbon vs High-Carbon Steel

Low-carbon steel demonstrates superior enamel adherence due to its lower carbon content, which promotes a smoother and more uniform oxide layer, enhancing enamel bonding. High-carbon steel's increased carbon content results in a more brittle surface prone to cracking, reducing enamel performance and durability. Enamel coatings on low-carbon steel exhibit better resistance to chipping and improved longevity compared to those on high-carbon steel.

Thermal Expansion and Enamel Compatibility

Low-carbon steel exhibits lower thermal expansion compared to high-carbon steel, making it more compatible with enamel coatings by reducing the risk of cracking during temperature fluctuations. High-carbon steel's higher thermal expansion can lead to enamel stress and potential detachment due to mismatch in expansion rates. Choosing low-carbon steel enhances enamel adherence, durability, and overall performance in enameled products.

Resistance to Cracking and Chipping: A Comparative Analysis

Low-carbon steel offers superior resistance to cracking and chipping in enameling due to its lower hardness and greater ductility, which allows the enamel coating to flex without fracturing. High-carbon steel, being harder and more brittle, tends to promote enamel cracking and chipping under thermal stress and mechanical impact. Thus, for applications requiring durable enamel finishes, low-carbon steel substrates significantly reduce failure rates related to enamel damage.

Cost and Availability: Low-Carbon vs High-Carbon Steel in Enameling

Low-carbon steel is more cost-effective and widely available for enameling applications compared to high-carbon steel, which tends to be pricier due to its increased hardness and alloy content. The abundance of low-carbon steel facilitates large-scale production of enameled products, making it the preferred choice in industries such as cookware and appliances. High-carbon steel's limited availability and higher cost restrict its use to specialized enameling tasks requiring enhanced durability and resistance.

Applications: When to Use Low-Carbon or High-Carbon Steel for Enamel Products

Low-carbon steel is ideal for enameling applications requiring excellent formability and weldability, such as cookware, appliances, and decorative panels, due to its softer, more ductile nature. High-carbon steel, with its increased hardness and wear resistance, is preferred for enamel-coated tools and industrial equipment where durability and impact resistance are critical. Selecting low-carbon steel enhances enamel adhesion and reduces cracking, while high-carbon steel supports enamel longevity in high-stress environments.

Choosing the Right Steel for Enameling: Key Considerations and Recommendations

Low-carbon steel is preferred for enameling due to its superior weldability and reduced risk of cracking during the firing process, making it ideal for intricate or large enameled surfaces. High-carbon steel offers greater hardness but poses challenges such as increased brittleness and higher susceptibility to thermal stress, which can lead to enamel chip-off and substrate deformation. Selecting low-carbon steel with a carbon content below 0.3% ensures better adhesion and durability of the enamel coating, optimizing both performance and aesthetic quality.

Low-carbon steel vs High-carbon steel (for enameling) Infographic

materialdif.com

materialdif.com