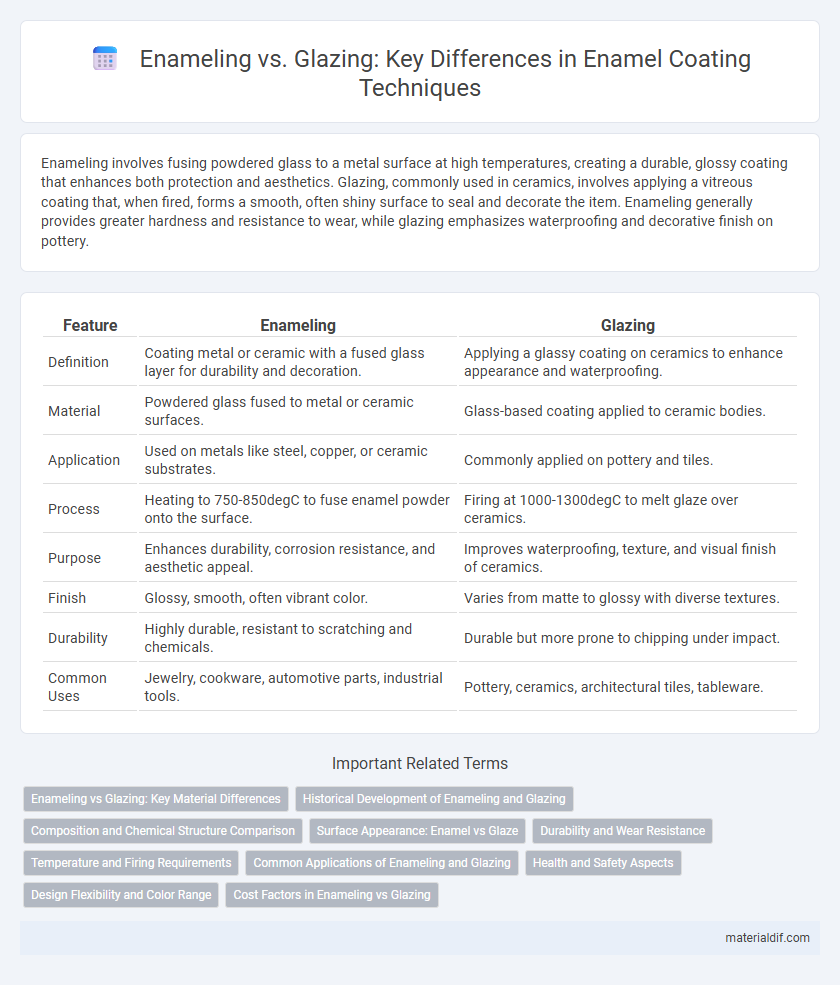

Enameling involves fusing powdered glass to a metal surface at high temperatures, creating a durable, glossy coating that enhances both protection and aesthetics. Glazing, commonly used in ceramics, involves applying a vitreous coating that, when fired, forms a smooth, often shiny surface to seal and decorate the item. Enameling generally provides greater hardness and resistance to wear, while glazing emphasizes waterproofing and decorative finish on pottery.

Table of Comparison

| Feature | Enameling | Glazing |

|---|---|---|

| Definition | Coating metal or ceramic with a fused glass layer for durability and decoration. | Applying a glassy coating on ceramics to enhance appearance and waterproofing. |

| Material | Powdered glass fused to metal or ceramic surfaces. | Glass-based coating applied to ceramic bodies. |

| Application | Used on metals like steel, copper, or ceramic substrates. | Commonly applied on pottery and tiles. |

| Process | Heating to 750-850degC to fuse enamel powder onto the surface. | Firing at 1000-1300degC to melt glaze over ceramics. |

| Purpose | Enhances durability, corrosion resistance, and aesthetic appeal. | Improves waterproofing, texture, and visual finish of ceramics. |

| Finish | Glossy, smooth, often vibrant color. | Varies from matte to glossy with diverse textures. |

| Durability | Highly durable, resistant to scratching and chemicals. | Durable but more prone to chipping under impact. |

| Common Uses | Jewelry, cookware, automotive parts, industrial tools. | Pottery, ceramics, architectural tiles, tableware. |

Enameling vs Glazing: Key Material Differences

Enameling involves fusing powdered glass to a metal surface at high temperatures, creating a durable, glossy coating resistant to corrosion and wear. Glazing typically refers to applying a vitreous layer to ceramics, enhancing aesthetic appeal and water resistance but lacking the metal adhesion seen in enameling. The key material difference lies in enameling's metallurgical bond and thermal fusion, whereas glazing relies on surface vitrification without chemical bonding to metals.

Historical Development of Enameling and Glazing

Enameling and glazing both evolved as ancient surface-coating techniques, with enameling dating back to the Bronze Age, prominently seen in Byzantine and Celtic artifacts where glassy substances fused to metal surfaces created durable, decorative finishes. Glazing, originating earlier in Mesopotamian and Egyptian pottery around 3000 BCE, involved applying silica-based vitreous coatings to ceramics, enhancing durability and aesthetic appeal. Over centuries, enameling advanced through European Renaissance metalwork, while glazing techniques diversified in Asian ceramics, reflecting distinct cultural innovations in material use and artistic expression.

Composition and Chemical Structure Comparison

Enameling involves fusing powdered glass mixed with metal oxides onto a substrate at high temperatures, creating a durable, glassy coating with a complex silica-based matrix bonded to metal ions. Glazing typically uses a vitreous coating composed mainly of silica, fluxes, and colorants that vitrify on ceramic surfaces, resulting in a smooth, non-metallic glass layer. The key chemical distinction lies in enameling's integration of metal ions into the silica network, enhancing hardness and adhesion, whereas glazing relies primarily on silica flux interactions forming a uniform, less chemically bonded glass film.

Surface Appearance: Enamel vs Glaze

Enamel creates a smooth, glossy surface with vibrant colors and high durability, making it ideal for decorative and protective coatings on metals and ceramics. In contrast, glaze forms a glass-like, often translucent layer that enhances texture and depth, commonly used on pottery to seal and waterproof. Differences in reflectivity and thickness between enamel and glaze significantly influence the finished product's surface appearance and tactile feel.

Durability and Wear Resistance

Enameling provides superior durability and wear resistance compared to glazing due to its glass-like coating that fuses directly to the metal surface during high-temperature firing. This process results in a hard, scratch-resistant finish ideal for utensils, jewelry, and industrial equipment. In contrast, glazing, commonly used on ceramics, forms a thinner, more porous layer that is more prone to chipping and wear over time.

Temperature and Firing Requirements

Enameling requires higher firing temperatures, typically between 1,350degF and 1,560degF (730degC to 850degC), to fuse powdered glass onto metal surfaces, ensuring a durable, glossy finish. In contrast, glazing ceramic involves firing at a broader range of temperatures, often between 1,800degF and 2,400degF (980degC to 1,300degC), depending on the clay body and glaze composition, to melt the glaze and form a smooth, glassy coating. The precise kiln temperature and duration directly influence the chemical bonding and surface quality unique to each technique.

Common Applications of Enameling and Glazing

Enameling is commonly applied in jewelry, decorative art, and cookware, providing a durable, glossy finish that resists corrosion and thermal shock. Glazing is primarily used in ceramics, pottery, and architectural tiles, creating a glass-like surface that enhances aesthetic appeal and improves waterproofing. Both techniques improve surface durability, but enameling suits metal substrates while glazing is ideal for clay-based materials.

Health and Safety Aspects

Enameling involves fusing powdered glass to metal at high temperatures, producing a durable, non-porous surface that resists bacteria and chemicals, thereby enhancing health and safety in applications like cookware and medical instruments. Glazing, commonly applied to ceramics, creates a smooth, glass-like coating that can contain lead or other toxic materials unless specifically formulated as food-safe, posing potential health risks if improperly used or fired. Proper ventilation and protective equipment during enameling prevent exposure to harmful fumes, while selecting lead-free glazes ensures safer ceramic products for consumer use.

Design Flexibility and Color Range

Enameling offers superior design flexibility compared to glazing, allowing for intricate patterns and a wider array of colors due to its ability to fuse powdered glass onto metal surfaces under high heat. The color range in enameling is vibrant and long-lasting, with the capability to layer multiple hues for nuanced effects. Glazing, typically applied to ceramics, provides a more limited palette and less variation in detail, making enameling the preferred choice for detailed, colorful designs.

Cost Factors in Enameling vs Glazing

Enameling typically incurs higher initial setup costs due to specialized equipment and high-temperature kilns, whereas glazing often requires less expensive materials and lower firing temperatures. Enameling's durability and resistance to wear can reduce long-term costs by minimizing the need for repairs or replacements. Glazing remains a budget-friendly option for decorative finishes but may lead to increased maintenance expenses over time.

Enameling vs Glazing Infographic

materialdif.com

materialdif.com