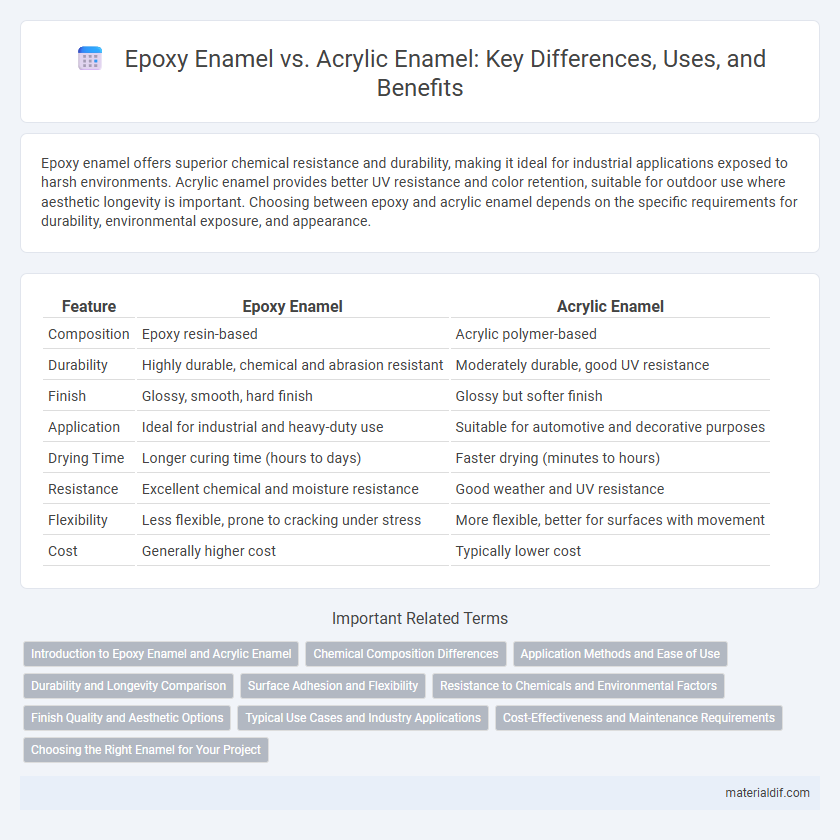

Epoxy enamel offers superior chemical resistance and durability, making it ideal for industrial applications exposed to harsh environments. Acrylic enamel provides better UV resistance and color retention, suitable for outdoor use where aesthetic longevity is important. Choosing between epoxy and acrylic enamel depends on the specific requirements for durability, environmental exposure, and appearance.

Table of Comparison

| Feature | Epoxy Enamel | Acrylic Enamel |

|---|---|---|

| Composition | Epoxy resin-based | Acrylic polymer-based |

| Durability | Highly durable, chemical and abrasion resistant | Moderately durable, good UV resistance |

| Finish | Glossy, smooth, hard finish | Glossy but softer finish |

| Application | Ideal for industrial and heavy-duty use | Suitable for automotive and decorative purposes |

| Drying Time | Longer curing time (hours to days) | Faster drying (minutes to hours) |

| Resistance | Excellent chemical and moisture resistance | Good weather and UV resistance |

| Flexibility | Less flexible, prone to cracking under stress | More flexible, better for surfaces with movement |

| Cost | Generally higher cost | Typically lower cost |

Introduction to Epoxy Enamel and Acrylic Enamel

Epoxy enamel is a durable coating known for its superior chemical resistance and strong adhesion, commonly used in industrial applications to protect metal surfaces from corrosion. Acrylic enamel offers excellent color retention and a glossy finish, favored for automotive and decorative uses due to its quick drying time and weather resistance. Both epoxy and acrylic enamels provide effective surface protection but differ in their formulation and ideal application environments.

Chemical Composition Differences

Epoxy enamel contains epoxy resins that provide superior chemical resistance and adhesion, making it ideal for industrial applications. Acrylic enamel is formulated with acrylic polymers, offering faster drying times and better UV resistance for outdoor use. The distinct chemical structures of epoxy and acrylic resins influence their durability, flexibility, and compatibility with various surfaces.

Application Methods and Ease of Use

Epoxy enamel is commonly applied using spray guns or brushes, providing a durable, chemical-resistant finish ideal for industrial surfaces, but it requires thorough surface preparation and precise mixing of resin and hardener. Acrylic enamel offers greater ease of use with simpler brush or spray applications and faster drying times, making it suitable for automotive and decorative purposes without extensive surface treatment. Both coatings demand careful handling, but acrylic enamel is often preferred for its user-friendly application and quicker curing process.

Durability and Longevity Comparison

Epoxy enamel offers superior durability and chemical resistance, making it ideal for industrial environments with heavy wear and exposure to harsh chemicals. Acrylic enamel provides moderate durability with enhanced UV resistance and color retention, suitable for exterior applications where weather resistance is critical. Epoxy enamel typically lasts longer in high-impact or corrosive settings, whereas acrylic enamel excels in maintaining appearance under prolonged sunlight exposure.

Surface Adhesion and Flexibility

Epoxy enamel exhibits superior surface adhesion due to its strong chemical bonding with substrates, making it ideal for metal surfaces requiring durability and resistance to abrasion. Acrylic enamel, while offering moderate adhesion, excels in flexibility, allowing painted surfaces to expand and contract without cracking, which is beneficial for materials exposed to temperature fluctuations. The choice between epoxy and acrylic enamel depends on the specific application needs, balancing the demand for adhesion strength against the requirement for surface flexibility.

Resistance to Chemicals and Environmental Factors

Epoxy enamel demonstrates superior resistance to chemicals such as acids, alkalis, and solvents, making it ideal for industrial and marine environments where exposure to harsh substances is frequent. Acrylic enamel offers good resistance to environmental factors like UV rays and weathering, maintaining gloss and color retention over time, but it is less effective against aggressive chemicals compared to epoxy. For applications requiring maximum chemical durability and corrosion protection, epoxy enamel provides a more robust solution, while acrylic enamel excels in outdoor aesthetic longevity.

Finish Quality and Aesthetic Options

Epoxy enamel offers a highly durable, glossy finish resistant to chemicals and moisture, making it ideal for industrial applications requiring long-lasting protection. Acrylic enamel provides a smoother, more vibrant aesthetic with superior color retention and faster drying times, preferred for automotive and decorative uses. The choice between epoxy and acrylic enamel hinges on balancing finish durability against a wider range of aesthetic options and color vibrancy.

Typical Use Cases and Industry Applications

Epoxy enamel is widely used in industrial applications requiring strong chemical resistance and durability, such as coatings for metal pipes, machinery, and marine equipment. Acrylic enamel is preferred in automotive and consumer goods industries due to its superior gloss, color retention, and UV resistance. Typical use cases for epoxy enamel include protective coatings in heavy industry, while acrylic enamel is favored for decorative finishes and exterior surfaces exposed to sunlight.

Cost-Effectiveness and Maintenance Requirements

Epoxy enamel offers superior cost-effectiveness due to its durable chemical resistance and longer lifespan, reducing the need for frequent repainting in industrial and marine environments. Acrylic enamel requires more regular maintenance because it is less resistant to chipping and UV degradation, leading to higher long-term upkeep costs. Choosing epoxy enamel minimizes overall maintenance expenses and extends coating longevity, especially where exposure to harsh conditions is a concern.

Choosing the Right Enamel for Your Project

Epoxy enamel offers superior chemical resistance and durability, making it ideal for industrial and heavy-duty applications where protection against corrosion and wear is essential. Acrylic enamel provides excellent color retention and UV resistance, perfect for automotive and decorative projects where a glossy, long-lasting finish is desired. Selecting the right enamel depends on the specific exposure conditions and performance requirements of your project.

Epoxy enamel vs Acrylic enamel Infographic

materialdif.com

materialdif.com