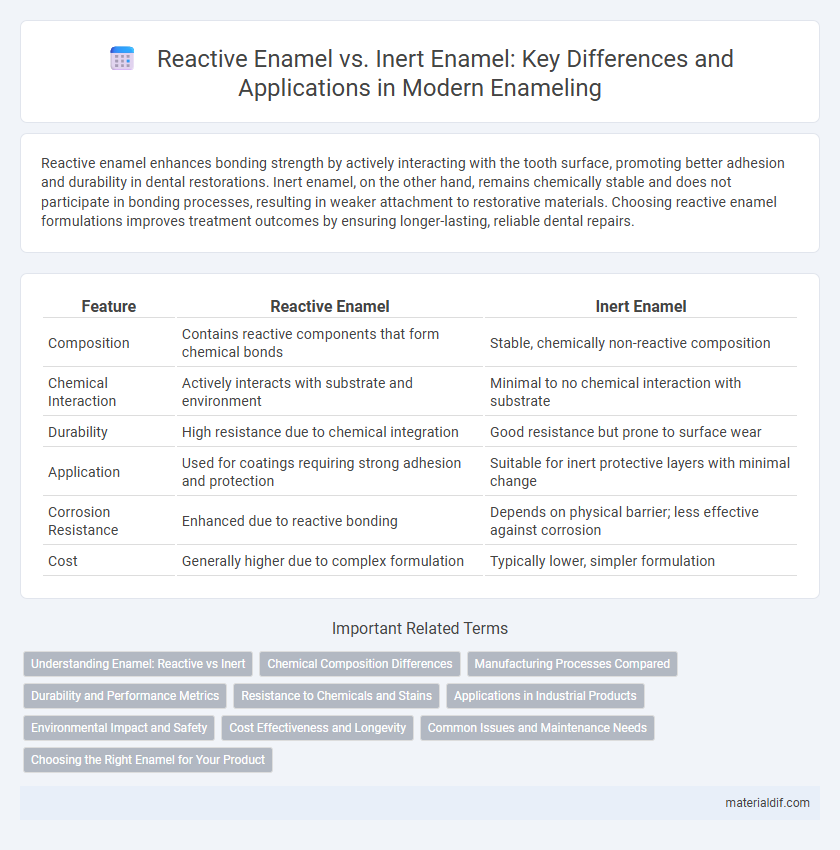

Reactive enamel enhances bonding strength by actively interacting with the tooth surface, promoting better adhesion and durability in dental restorations. Inert enamel, on the other hand, remains chemically stable and does not participate in bonding processes, resulting in weaker attachment to restorative materials. Choosing reactive enamel formulations improves treatment outcomes by ensuring longer-lasting, reliable dental repairs.

Table of Comparison

| Feature | Reactive Enamel | Inert Enamel |

|---|---|---|

| Composition | Contains reactive components that form chemical bonds | Stable, chemically non-reactive composition |

| Chemical Interaction | Actively interacts with substrate and environment | Minimal to no chemical interaction with substrate |

| Durability | High resistance due to chemical integration | Good resistance but prone to surface wear |

| Application | Used for coatings requiring strong adhesion and protection | Suitable for inert protective layers with minimal change |

| Corrosion Resistance | Enhanced due to reactive bonding | Depends on physical barrier; less effective against corrosion |

| Cost | Generally higher due to complex formulation | Typically lower, simpler formulation |

Understanding Enamel: Reactive vs Inert

Reactive enamel contains oxides that interact chemically during firing to create vibrant colors and textures, making it ideal for artistic and decorative applications. Inert enamel remains chemically stable throughout the firing process, ensuring durability and resistance to corrosion, commonly used in industrial and functional coatings. Understanding these differences helps in selecting the appropriate enamel type for specific aesthetic or protective purposes.

Chemical Composition Differences

Reactive enamel contains active oxides such as calcium oxide and sodium oxide that facilitate chemical bonding with the substrate, enhancing adhesion and durability. Inert enamel primarily consists of stable silica-based compounds with minimal reactive oxides, resulting in a more resistant but less chemically interactive surface. The distinct chemical compositions influence the enamel's performance in various applications, with reactive enamel promoting stronger integration and inert enamel offering greater chemical stability.

Manufacturing Processes Compared

Reactive enamel undergoes manufacturing processes involving chemical reactions that enhance adhesion and durability, typically through the inclusion of fluxing agents and metal oxides that promote bonding with substrates. Inert enamel manufacturing focuses on producing stable, non-reactive coatings by melting and fusing finely ground glass particles, resulting in a smooth, corrosion-resistant surface without altering substrate properties. The choice between reactive and inert enamel processes directly affects application suitability, with reactive enamels favored for metal surfaces requiring strong chemical bonds and inert enamels preferred for protective, decorative finishes.

Durability and Performance Metrics

Reactive enamel exhibits higher durability due to its ability to chemically bond with the substrate, resulting in enhanced resistance to chipping and corrosion. Inert enamel, while providing a stable and visually consistent coating, typically shows lower adhesion strength and reduced performance under mechanical stress. Performance metrics such as abrasion resistance and lifespan consistently favor reactive enamel in demanding industrial applications.

Resistance to Chemicals and Stains

Reactive enamel forms a strong chemical bond with the substrate, enhancing its resistance to chemicals and stains by preventing penetration and degradation. Inert enamel, lacking chemical interaction, relies solely on its physical barrier properties, which can be less effective against aggressive agents. Studies show that reactive enamels maintain color and integrity longer under exposure to acids, alkalis, and organic solvents compared to inert counterparts.

Applications in Industrial Products

Reactive enamel, characterized by its chemical reactivity and ability to bond with substrates, is widely used in industrial products requiring strong adhesion and corrosion resistance, such as cookware coatings and automotive parts. Inert enamel offers excellent durability and resistance to chemical attack, making it ideal for applications like electrical insulators and protective coatings in chemical processing equipment. The choice between reactive and inert enamel depends on the specific performance requirements, including temperature tolerance, mechanical strength, and environmental exposure.

Environmental Impact and Safety

Reactive enamel interacts chemically with substrate materials, which can improve adhesion but may release volatile organic compounds (VOCs) during application, raising environmental and health concerns. Inert enamel, composed of stable, non-reactive compounds, minimizes emissions and reduces risks to applicators and surrounding ecosystems. Choosing inert enamel formulations supports safer handling and lowers the environmental footprint by limiting hazardous substance release.

Cost Effectiveness and Longevity

Reactive enamel offers superior cost effectiveness by enhancing adhesion and durability, reducing maintenance and replacement frequency compared to inert enamel. Inert enamel, while often less expensive initially, typically lacks the reactive properties that extend coating longevity, potentially increasing long-term costs due to more frequent recoating. Selection of reactive enamel is advantageous for environments demanding high performance and extended service life, balancing upfront investment with overall durability.

Common Issues and Maintenance Needs

Reactive enamel often experiences chemical changes when exposed to moisture or acids, leading to discoloration, etching, and increased wear, which requires frequent cleaning and protective coatings to maintain durability. Inert enamel, being chemically stable, resists these issues but may develop surface cracks or chips due to physical impact, necessitating periodic inspections and gentle cleaning to preserve integrity. Both types demand tailored maintenance strategies to address their specific vulnerabilities and extend lifespan.

Choosing the Right Enamel for Your Product

Reactive enamel chemically bonds with the substrate, enhancing adhesion and durability, making it ideal for products exposed to high stress or environmental factors. Inert enamel forms a physical barrier without chemical interaction, providing excellent corrosion resistance and color stability, suitable for decorative or low-impact applications. Selecting the right enamel depends on product requirements such as durability, exposure conditions, and desired finish quality.

Reactive enamel vs Inert enamel Infographic

materialdif.com

materialdif.com