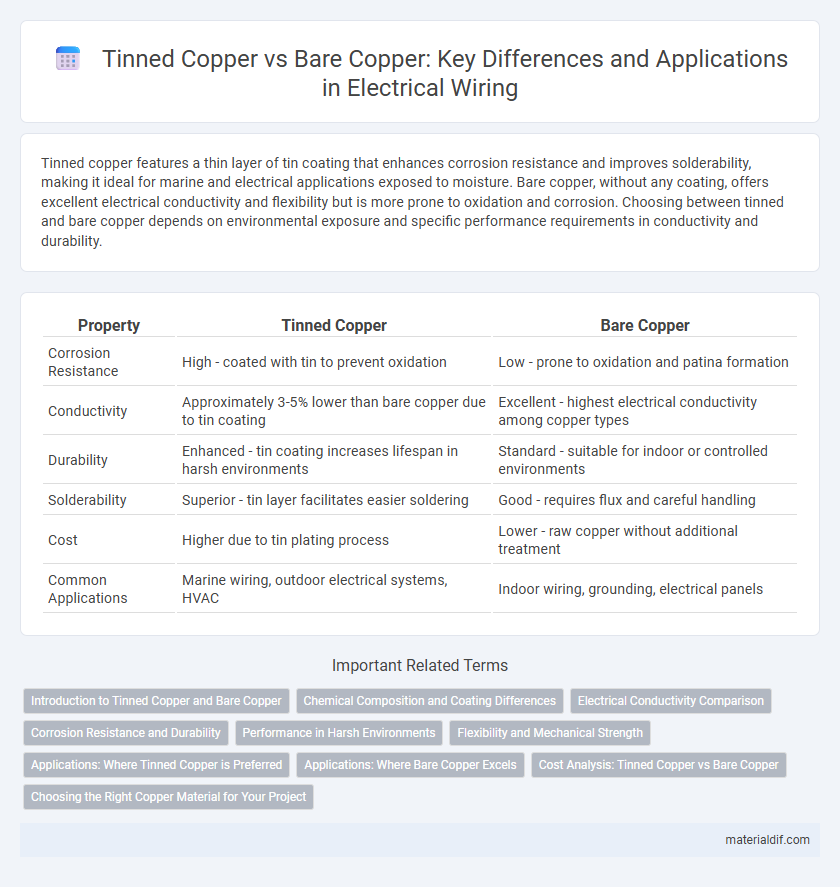

Tinned copper features a thin layer of tin coating that enhances corrosion resistance and improves solderability, making it ideal for marine and electrical applications exposed to moisture. Bare copper, without any coating, offers excellent electrical conductivity and flexibility but is more prone to oxidation and corrosion. Choosing between tinned and bare copper depends on environmental exposure and specific performance requirements in conductivity and durability.

Table of Comparison

| Property | Tinned Copper | Bare Copper |

|---|---|---|

| Corrosion Resistance | High - coated with tin to prevent oxidation | Low - prone to oxidation and patina formation |

| Conductivity | Approximately 3-5% lower than bare copper due to tin coating | Excellent - highest electrical conductivity among copper types |

| Durability | Enhanced - tin coating increases lifespan in harsh environments | Standard - suitable for indoor or controlled environments |

| Solderability | Superior - tin layer facilitates easier soldering | Good - requires flux and careful handling |

| Cost | Higher due to tin plating process | Lower - raw copper without additional treatment |

| Common Applications | Marine wiring, outdoor electrical systems, HVAC | Indoor wiring, grounding, electrical panels |

Introduction to Tinned Copper and Bare Copper

Tinned copper consists of copper wire coated with a thin layer of tin to enhance corrosion resistance and prevent oxidation, making it ideal for marine and electrical applications. Bare copper, on the other hand, is uncoated copper known for its excellent electrical conductivity and flexibility, commonly used in building wiring and electrical equipment. The choice between tinned and bare copper depends largely on environmental exposure and performance requirements in specific industries.

Chemical Composition and Coating Differences

Tinned copper consists of bare copper wire coated with a thin layer of tin, which provides enhanced corrosion resistance and oxidation prevention, making it suitable for marine or industrial environments. The chemical composition of tinned copper retains the high conductivity of pure copper while the tin coating, typically 99.9% pure, acts as a protective barrier against environmental factors. Bare copper, composed purely of uncoated high-purity copper (approximately 99.9% copper), offers superior electrical conductivity but is more susceptible to corrosion and tarnishing over time without protective coating.

Electrical Conductivity Comparison

Tinned copper features a thin layer of tin coating that provides enhanced corrosion resistance while maintaining excellent electrical conductivity, typically around 97% of the conductivity of bare copper. Bare copper, being uncoated, offers maximum electrical conductivity, approximately 59.6 million Siemens per meter (MS/m), which is superior for pure electrical performance. Although bare copper exhibits slightly higher conductivity, tinned copper is preferred in environments requiring corrosion protection without significantly compromising electrical efficiency.

Corrosion Resistance and Durability

Tinned copper offers superior corrosion resistance compared to bare copper due to its thin layer of tin coating, which protects against oxidation and environmental factors such as moisture and chemicals. This enhanced protection extends the lifespan of tinned copper in harsh or marine environments, making it more durable for long-term applications. Bare copper, while naturally conductive, is more prone to corrosion and requires additional protective measures in corrosive settings.

Performance in Harsh Environments

Tinned copper offers superior corrosion resistance compared to bare copper, making it ideal for harsh environments with high moisture or chemical exposure. The thin tin coating prevents oxidation, enhancing conductivity and longevity in marine, industrial, and outdoor applications. Bare copper, while cost-effective, is more susceptible to tarnishing and degradation under extreme environmental conditions.

Flexibility and Mechanical Strength

Tinned copper offers enhanced corrosion resistance while maintaining similar flexibility to bare copper, making it suitable for applications requiring frequent movement or bending. Bare copper typically exhibits higher mechanical strength, providing greater durability under mechanical stress and resisting deformation in structural uses. Choosing between tinned and bare copper depends on balancing the need for flexibility with the environmental protection versus mechanical robustness.

Applications: Where Tinned Copper is Preferred

Tinned copper is preferred in marine and outdoor electrical applications due to its enhanced resistance to corrosion and oxidation compared to bare copper. It is commonly used in wiring for ships, coastal installations, and HVAC systems where exposure to moisture and harsh environments is frequent. Tinned copper's durability in these conditions extends the lifespan of electrical components and ensures reliable conductivity.

Applications: Where Bare Copper Excels

Bare copper excels in grounding systems, electrical wiring, and applications requiring high conductivity due to its excellent electrical and thermal properties. It is widely used in building wiring, transformers, and motors where corrosion resistance is less critical, and cost efficiency is essential. Industries such as construction and electrical manufacturing prefer bare copper for its superior conductivity and mechanical strength in exposed or indoor environments.

Cost Analysis: Tinned Copper vs Bare Copper

Tinned copper typically incurs higher upfront costs compared to bare copper due to the additional tinning process, which enhances corrosion resistance and lifespan. However, tinned copper's durability reduces long-term maintenance and replacement expenses, making it cost-effective in harsh or marine environments. Bare copper offers lower initial investment but may require more frequent replacement, increasing total lifecycle costs in corrosive conditions.

Choosing the Right Copper Material for Your Project

Tinned copper offers superior corrosion resistance and enhanced solderability, making it ideal for marine or outdoor electrical applications. Bare copper provides excellent electrical conductivity and is generally more cost-effective, suitable for indoor or protected environments. Evaluating environmental exposure, conductivity requirements, and budget constraints ensures the selection of the appropriate copper type for your project.

Tinned Copper vs Bare Copper Infographic

materialdif.com

materialdif.com