Copper offers superior thermal and electrical conductivity compared to stainless steel, making it ideal for applications requiring efficient heat transfer and electrical performance. While stainless steel provides enhanced corrosion resistance and durability, copper's antimicrobial properties and malleability make it favorable for plumbing and decorative uses. Despite copper's higher cost and susceptibility to oxidation, its unique combination of conductivity and antimicrobial benefits often outweighs these drawbacks in specific industries.

Table of Comparison

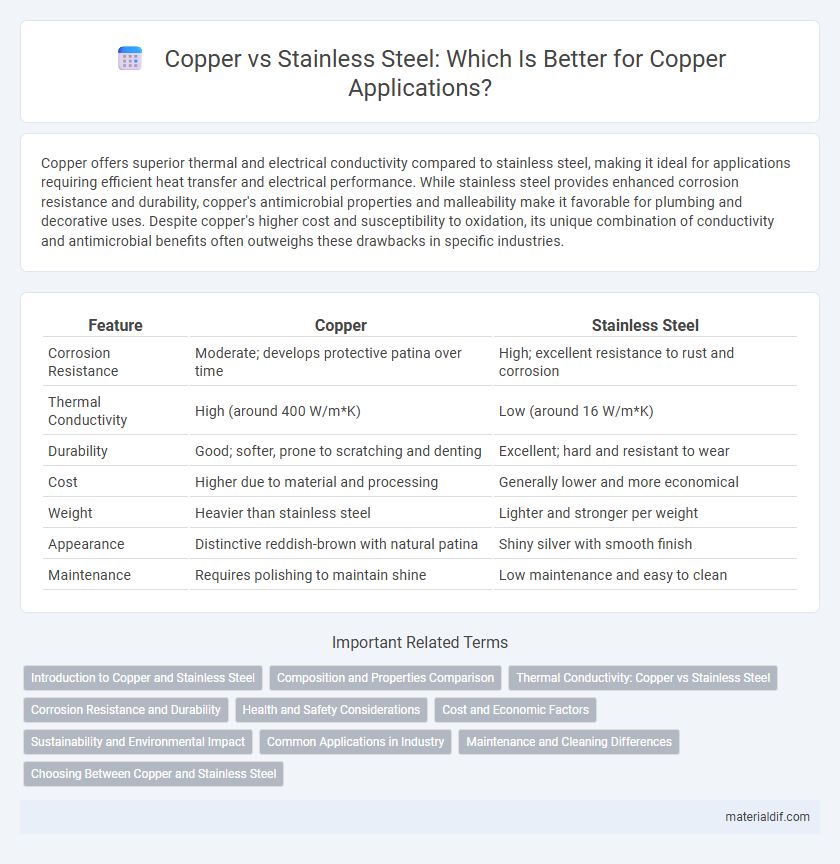

| Feature | Copper | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Moderate; develops protective patina over time | High; excellent resistance to rust and corrosion |

| Thermal Conductivity | High (around 400 W/m*K) | Low (around 16 W/m*K) |

| Durability | Good; softer, prone to scratching and denting | Excellent; hard and resistant to wear |

| Cost | Higher due to material and processing | Generally lower and more economical |

| Weight | Heavier than stainless steel | Lighter and stronger per weight |

| Appearance | Distinctive reddish-brown with natural patina | Shiny silver with smooth finish |

| Maintenance | Requires polishing to maintain shine | Low maintenance and easy to clean |

Introduction to Copper and Stainless Steel

Copper, a highly conductive metal known for its excellent thermal and electrical properties, is widely used in electrical wiring and plumbing applications. Stainless steel, an alloy primarily composed of iron, chromium, and nickel, offers exceptional corrosion resistance and strength, making it ideal for kitchenware and industrial equipment. Comparing copper and stainless steel highlights copper's superior conductivity versus stainless steel's durability and corrosion resistance.

Composition and Properties Comparison

Copper consists primarily of pure copper with trace impurities, offering excellent electrical and thermal conductivity, while stainless steel is an alloy composed mainly of iron, chromium (typically 10.5-20%), and nickel, providing superior corrosion resistance and mechanical strength. Copper's softness and high malleability contrast with the hardness and durability of stainless steel, making stainless steel more suitable for structural applications. The natural antimicrobial properties of copper differ significantly from stainless steel's inert surface, influencing their use in healthcare and food industries.

Thermal Conductivity: Copper vs Stainless Steel

Copper exhibits a thermal conductivity of approximately 400 W/m*K, significantly higher than stainless steel's range of 15-25 W/m*K, making copper ideal for efficient heat transfer applications. This substantial difference allows copper to rapidly conduct and dissipate heat, whereas stainless steel's lower conductivity results in slower heat distribution and retention. Industries requiring high thermal performance, such as electronics cooling and heat exchangers, often favor copper due to its superior thermal conductivity properties.

Corrosion Resistance and Durability

Copper exhibits excellent corrosion resistance due to its natural patina formation, which protects the metal from further oxidation and environmental damage. Stainless steel offers superior durability and resistance to mechanical wear, maintaining structural integrity in harsh conditions, but may be prone to pitting corrosion in chloride-rich environments. When selecting materials, copper is ideal for applications requiring antimicrobial properties and superior corrosion resistance, while stainless steel suits scenarios demanding higher strength and impact resistance.

Health and Safety Considerations

Copper offers natural antimicrobial properties that can reduce the growth of harmful bacteria on surfaces, enhancing health safety in environments like kitchens and hospitals. Stainless steel, while durable and corrosion-resistant, lacks inherent antimicrobial qualities and may require frequent cleaning to maintain hygienic conditions. Both materials are non-toxic, but copper's ability to inhibit microbial contamination provides a distinct advantage in health-sensitive applications.

Cost and Economic Factors

Copper generally has a higher upfront cost compared to stainless steel due to its raw material price and extraction expenses. However, copper offers superior thermal and electrical conductivity, reducing energy costs in specific applications. Stainless steel tends to be more cost-effective for projects requiring corrosion resistance and structural strength, balancing initial investment with long-term durability.

Sustainability and Environmental Impact

Copper exhibits superior sustainability compared to stainless steel due to its 100% recyclability and lower energy requirements for recycling processes, significantly reducing carbon emissions. Copper's natural antimicrobial properties reduce the need for chemical cleaning agents, minimizing environmental pollution. In contrast, stainless steel production involves higher energy consumption and mining impacts, contributing to greater ecological footprint and resource depletion.

Common Applications in Industry

Copper is widely used in electrical wiring, plumbing, and heat exchangers due to its excellent conductivity and corrosion resistance. Stainless steel finds application in food processing, chemical containers, and medical instruments because of its durability and resistance to high temperatures and chemicals. Both materials are essential in manufacturing, with copper favored for electrical and thermal applications, while stainless steel is preferred for structural and sanitary uses.

Maintenance and Cleaning Differences

Copper requires regular polishing to prevent tarnish and maintain its natural shine, whereas stainless steel is low-maintenance and resists corrosion and staining without frequent care. Cleaning copper involves gentle, acidic solutions such as lemon juice or vinegar to remove patina, while stainless steel can be cleaned with standard detergents and mild abrasives without damage. Copper's reactive surface demands more attentive maintenance, making stainless steel the preferred choice for ease of cleaning and durability in busy environments.

Choosing Between Copper and Stainless Steel

Choosing between copper and stainless steel depends on factors such as electrical conductivity, corrosion resistance, and aesthetic appeal. Copper offers superior electrical and thermal conductivity, making it ideal for electrical wiring and heat exchangers, while stainless steel excels in corrosion resistance and durability, especially in harsh environments. Consider the specific application requirements, budget, and maintenance needs to determine the most suitable material.

Copper vs Stainless Steel Infographic

materialdif.com

materialdif.com