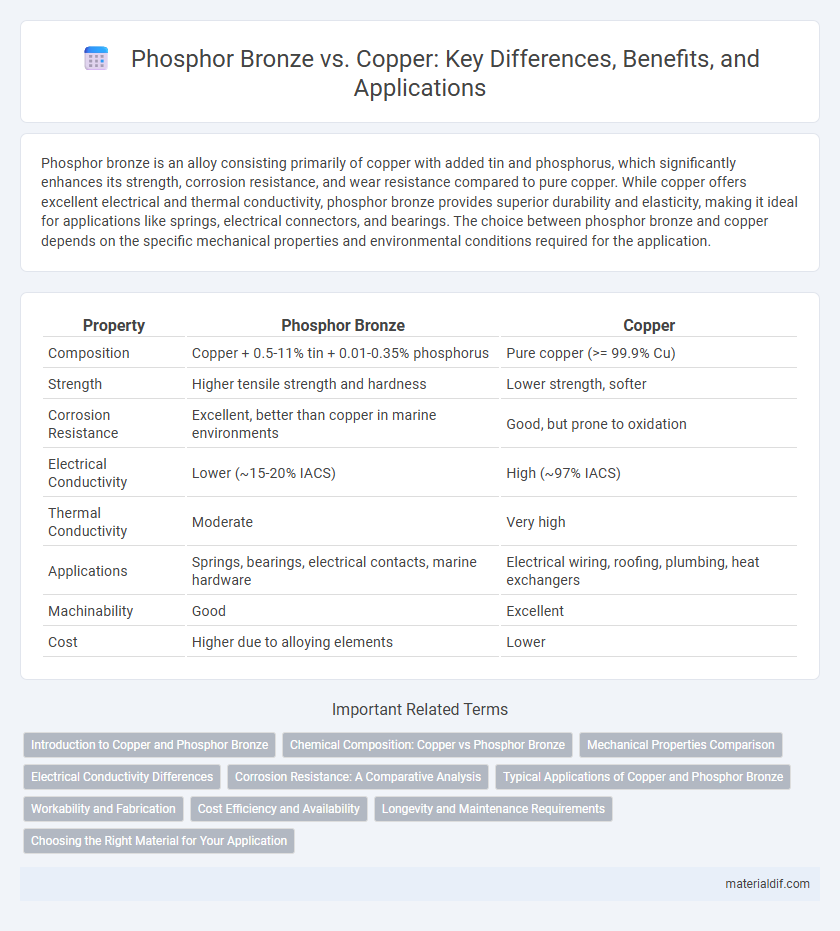

Phosphor bronze is an alloy consisting primarily of copper with added tin and phosphorus, which significantly enhances its strength, corrosion resistance, and wear resistance compared to pure copper. While copper offers excellent electrical and thermal conductivity, phosphor bronze provides superior durability and elasticity, making it ideal for applications like springs, electrical connectors, and bearings. The choice between phosphor bronze and copper depends on the specific mechanical properties and environmental conditions required for the application.

Table of Comparison

| Property | Phosphor Bronze | Copper |

|---|---|---|

| Composition | Copper + 0.5-11% tin + 0.01-0.35% phosphorus | Pure copper (>= 99.9% Cu) |

| Strength | Higher tensile strength and hardness | Lower strength, softer |

| Corrosion Resistance | Excellent, better than copper in marine environments | Good, but prone to oxidation |

| Electrical Conductivity | Lower (~15-20% IACS) | High (~97% IACS) |

| Thermal Conductivity | Moderate | Very high |

| Applications | Springs, bearings, electrical contacts, marine hardware | Electrical wiring, roofing, plumbing, heat exchangers |

| Machinability | Good | Excellent |

| Cost | Higher due to alloying elements | Lower |

Introduction to Copper and Phosphor Bronze

Copper, a highly conductive metal known for its excellent electrical and thermal properties, is widely used in electrical wiring and plumbing. Phosphor bronze, an alloy of copper with tin and a small amount of phosphorus, offers enhanced strength, corrosion resistance, and fatigue durability compared to pure copper. These attributes make phosphor bronze ideal for applications requiring superior mechanical properties while maintaining the advantageous conductivity of copper.

Chemical Composition: Copper vs Phosphor Bronze

Phosphor bronze is an alloy that primarily consists of copper combined with tin (usually 0.5-11%) and a small amount of phosphorus (0.01-0.35%), enhancing its strength, wear resistance, and corrosion resistance compared to pure copper. Pure copper contains 99.9% copper with minimal impurities, offering excellent electrical and thermal conductivity but lower mechanical strength. The addition of tin and phosphorus in phosphor bronze significantly alters its chemical composition, resulting in improved durability while sacrificing some of copper's inherent conductivity properties.

Mechanical Properties Comparison

Phosphor bronze exhibits higher tensile strength and improved fatigue resistance compared to pure copper, making it ideal for applications requiring durability under stress. Its enhanced hardness and wear resistance result from the addition of phosphorus and tin, which also contribute to better corrosion resistance. Copper, although more ductile and conductive, lacks the mechanical robustness of phosphor bronze in demanding environments.

Electrical Conductivity Differences

Phosphor bronze, an alloy of copper with tin and phosphorus, exhibits lower electrical conductivity compared to pure copper due to the presence of alloying elements that disrupt electron flow. Copper has an electrical conductivity of approximately 59.6 million Siemens per meter (MS/m), making it one of the best conductors, whereas phosphor bronze typically ranges between 7 to 15 MS/m. This significant difference makes pure copper the preferred choice for applications requiring high electrical conductivity, while phosphor bronze is utilized where strength and corrosion resistance are prioritized.

Corrosion Resistance: A Comparative Analysis

Phosphor bronze exhibits superior corrosion resistance compared to pure copper, primarily due to the addition of tin and phosphorus, which form a protective oxide layer that mitigates oxidation. In marine and industrial environments, phosphor bronze alloys outperform copper by resisting saltwater and chemical corrosion more effectively, thereby extending component lifespan. This enhanced durability makes phosphor bronze a preferred choice in applications requiring high corrosion resistance, such as bearings, springs, and electrical connectors.

Typical Applications of Copper and Phosphor Bronze

Copper is widely used in electrical wiring, plumbing, and electronics due to its excellent electrical conductivity and corrosion resistance, making it ideal for power generation and distribution systems. Phosphor bronze, an alloy of copper with tin and phosphorus, is commonly applied in manufacturing springs, bearings, and electrical connectors thanks to its superior strength, fatigue resistance, and wear properties. The choice between copper and phosphor bronze typically depends on the need for electrical conductivity or mechanical durability in various industrial and consumer applications.

Workability and Fabrication

Phosphor bronze offers superior workability compared to pure copper due to its increased strength and elasticity, enabling easier machining and forming without cracking. Fabrication processes such as stamping, bending, and welding are more efficient with phosphor bronze because of its enhanced resistance to fatigue and wear. Pure copper, while excellent for electrical conductivity, is softer and more prone to deformation, making phosphor bronze a preferred choice for components requiring durability and precise fabrication.

Cost Efficiency and Availability

Phosphor bronze generally has higher material costs compared to pure copper due to the addition of tin and phosphorus, which enhance its strength and corrosion resistance. Copper remains more cost-efficient and widely available, making it the preferred choice for large-scale electrical and plumbing applications where budget constraints are critical. Availability of copper is supported by extensive global mining operations, whereas phosphor bronze is produced in smaller quantities, impacting its overall cost and supply consistency.

Longevity and Maintenance Requirements

Phosphor Bronze offers superior longevity compared to pure copper due to its enhanced resistance to corrosion, wear, and fatigue, making it ideal for applications requiring extended durability. Maintenance requirements for phosphor bronze are lower than copper, as it resists tarnishing and degradation without frequent cleaning or protective coatings. Copper, while more malleable, tends to oxidize and corrode faster, necessitating more regular upkeep to maintain its appearance and structural integrity.

Choosing the Right Material for Your Application

Phosphor bronze, an alloy of copper with tin and phosphorus, offers enhanced strength, corrosion resistance, and fatigue durability compared to pure copper, making it ideal for applications requiring high mechanical performance and wear resistance. Pure copper excels in electrical and thermal conductivity, making it the preferred choice for electrical wiring, heat exchangers, and electronic components. Selecting between phosphor bronze and copper depends on balancing conductivity needs against mechanical strength and environmental conditions specific to your application's requirements.

Phosphor Bronze vs Copper Infographic

materialdif.com

materialdif.com