Copper plates offer a flat, uniform surface ideal for precise metalworking and electrical applications, while copper discs provide a rounded shape suited for crafting coins, medallions, and decorative items. The choice between copper plate and copper disc depends on the project's requirements for shape, thickness, and surface area. Copper plates are typically easier to cut and shape into custom forms, whereas copper discs are pre-cut for specific uses requiring symmetrical design.

Table of Comparison

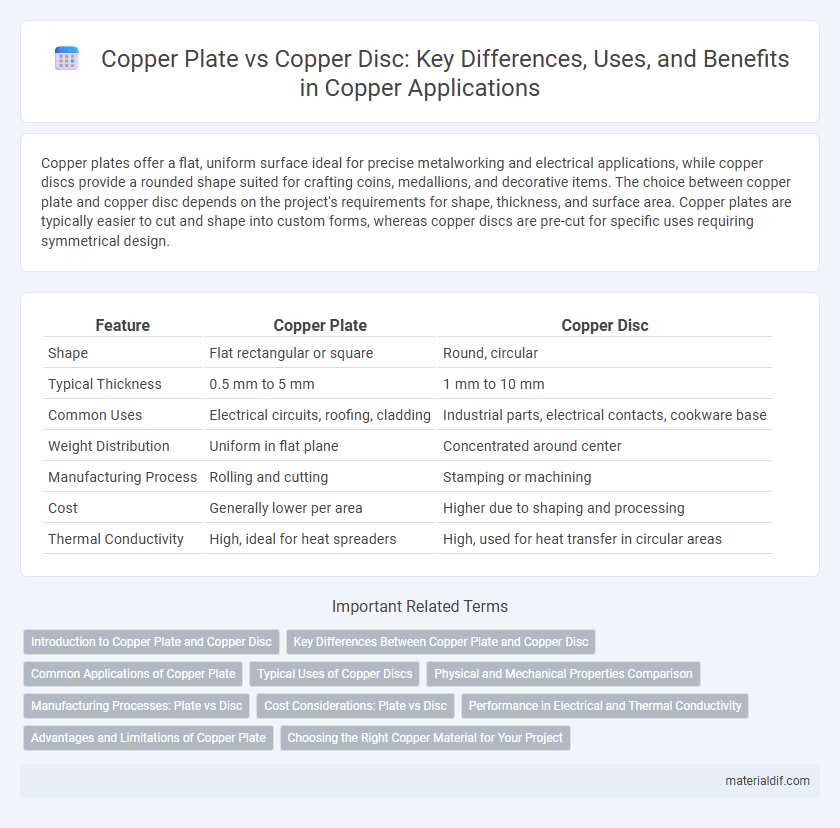

| Feature | Copper Plate | Copper Disc |

|---|---|---|

| Shape | Flat rectangular or square | Round, circular |

| Typical Thickness | 0.5 mm to 5 mm | 1 mm to 10 mm |

| Common Uses | Electrical circuits, roofing, cladding | Industrial parts, electrical contacts, cookware base |

| Weight Distribution | Uniform in flat plane | Concentrated around center |

| Manufacturing Process | Rolling and cutting | Stamping or machining |

| Cost | Generally lower per area | Higher due to shaping and processing |

| Thermal Conductivity | High, ideal for heat spreaders | High, used for heat transfer in circular areas |

Introduction to Copper Plate and Copper Disc

Copper plates and copper discs are essential materials in various industrial and artisanal applications due to their excellent electrical conductivity and corrosion resistance. Copper plates typically offer a flat, uniform surface ideal for fabrication, electrical components, and heat exchangers, whereas copper discs provide a compact, rounded form suited for specialized uses like coinage, electronics, and laboratory experiments. Differences in thickness, diameter, and manufacturing processes influence their suitability for specific technical and decorative purposes.

Key Differences Between Copper Plate and Copper Disc

Copper plates feature flat, rectangular surfaces ideal for large-area applications and uniform heat distribution, while copper discs are typically circular, suited for precision tasks and compact designs. The thickness and purity of copper plates allow for robust structural uses, whereas copper discs often emphasize conductivity and quick thermal response in electronics. Manufacturing techniques differ, with plates usually produced by rolling and discs by cutting or stamping, influencing their respective material grain and mechanical properties.

Common Applications of Copper Plate

Copper plates are commonly utilized in electrical circuit boards, heat exchangers, and roofing due to their excellent conductivity and corrosion resistance. Their flat, thin form makes them ideal for precise industrial applications such as printed circuit boards and architectural cladding. Unlike copper discs, copper plates offer easier integration into layered manufacturing and large surface-area projects.

Typical Uses of Copper Discs

Copper discs are commonly used in electrical and thermal applications due to their excellent conductivity and uniform shape, making them ideal for heat sinks, electrodes, and precision components in electronics. Their flat, consistent surface allows for reliable contact in electrical terminals and efficient heat dissipation in thermal management systems. Copper discs also find use in scientific experiments and industrial manufacturing processes where precise metal properties and dimensional accuracy are required.

Physical and Mechanical Properties Comparison

Copper plates exhibit higher structural rigidity and tensile strength compared to copper discs due to their uniform thickness and larger surface area, making them ideal for applications requiring enhanced load-bearing capacity. Copper discs, with their compact and rounded geometry, typically offer superior thermal conductivity and ease of machining, beneficial for precision components. The physical density of copper remains consistent across both forms, but mechanical performance varies significantly based on shape, thickness, and manufacturing processes.

Manufacturing Processes: Plate vs Disc

Copper plates are typically produced through continuous casting followed by rolling to achieve uniform thickness, making them ideal for applications requiring high structural integrity and flatness. Copper discs, on the other hand, are often manufactured by blanking or stamping from copper sheets, allowing precise circular shapes suitable for electrical contacts or decorative elements. The plate manufacturing process emphasizes thickness control and surface finish, while disc production focuses on dimensional accuracy and edge quality.

Cost Considerations: Plate vs Disc

Copper plates generally offer a more cost-effective option for large-scale applications due to lower production complexity and material waste compared to copper discs. Copper discs often involve higher manufacturing costs because of precision cutting and shaping requirements, which can increase overall expenses for small or specialized projects. Evaluating project scale and precision needs helps determine whether the affordability of copper plates outweighs the enhanced customization and performance benefits of copper discs.

Performance in Electrical and Thermal Conductivity

Copper plates exhibit superior electrical and thermal conductivity due to their larger surface area and uniform thickness, enabling efficient current flow and heat dissipation. Copper discs, while compact, often have slightly reduced performance caused by edge effects and potential grain boundary scattering. For applications demanding maximum conductivity, copper plates generally outperform copper discs.

Advantages and Limitations of Copper Plate

Copper plates offer superior surface uniformity and higher conductivity compared to copper discs, enhancing their effectiveness in electrical and thermal applications. They provide a larger, more stable contact area, reducing resistance and wear over time, but their rigidity limits flexibility in complex or curved installations. Cost and manufacturing complexity pose limitations, as producing thin copper plates can be more expensive and time-consuming than stamping copper discs.

Choosing the Right Copper Material for Your Project

Copper plates offer a flat, uniform surface ideal for applications requiring precise dimensional stability and consistent electrical conductivity. Copper discs provide enhanced versatility for crafting, stamping, and heat dissipation due to their compact, rounded shape and ease of handling. Selecting between copper plate and copper disc depends on project requirements such as surface area, thermal conductivity, and fabrication methods.

Copper Plate vs Copper Disc Infographic

materialdif.com

materialdif.com