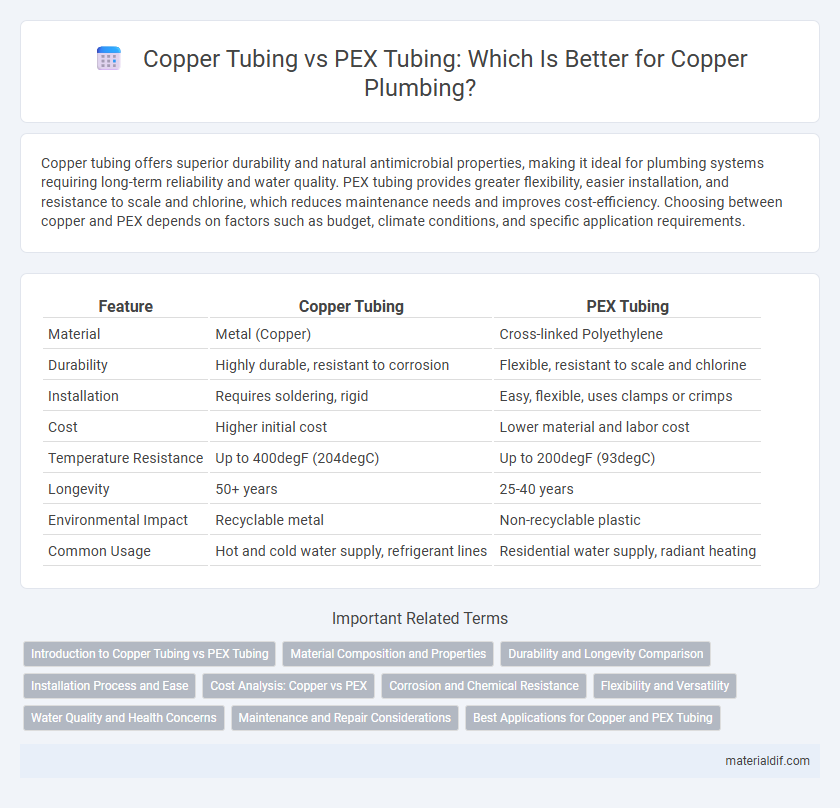

Copper tubing offers superior durability and natural antimicrobial properties, making it ideal for plumbing systems requiring long-term reliability and water quality. PEX tubing provides greater flexibility, easier installation, and resistance to scale and chlorine, which reduces maintenance needs and improves cost-efficiency. Choosing between copper and PEX depends on factors such as budget, climate conditions, and specific application requirements.

Table of Comparison

| Feature | Copper Tubing | PEX Tubing |

|---|---|---|

| Material | Metal (Copper) | Cross-linked Polyethylene |

| Durability | Highly durable, resistant to corrosion | Flexible, resistant to scale and chlorine |

| Installation | Requires soldering, rigid | Easy, flexible, uses clamps or crimps |

| Cost | Higher initial cost | Lower material and labor cost |

| Temperature Resistance | Up to 400degF (204degC) | Up to 200degF (93degC) |

| Longevity | 50+ years | 25-40 years |

| Environmental Impact | Recyclable metal | Non-recyclable plastic |

| Common Usage | Hot and cold water supply, refrigerant lines | Residential water supply, radiant heating |

Introduction to Copper Tubing vs PEX Tubing

Copper tubing offers superior durability and heat resistance, making it ideal for hot and cold water supply lines in residential and commercial plumbing. PEX tubing provides flexibility, cost-effectiveness, and ease of installation, which is advantageous for complex piping layouts and retrofit projects. Both materials comply with plumbing codes, but copper's antimicrobial properties and long lifespan contrast with PEX's resistance to freezing and chemical corrosion.

Material Composition and Properties

Copper tubing is composed of pure copper, known for its excellent thermal conductivity, corrosion resistance, and durability, making it ideal for high-temperature applications. PEX tubing consists of cross-linked polyethylene, a flexible plastic polymer that offers superior resistance to scale, chlorine, and freezing compared to copper. The rigid structure of copper provides strength and longevity, while PEX tubing's elasticity reduces joint failures and simplifies installation in complex plumbing systems.

Durability and Longevity Comparison

Copper tubing offers exceptional durability with a lifespan often exceeding 50 years, resisting corrosion and high temperatures better than most alternatives. PEX tubing provides flexibility and ease of installation but typically has a shorter lifespan, ranging from 25 to 40 years under optimal conditions. Copper's resistance to UV radiation, microbial growth, and mechanical damage contributes to its superior longevity compared to PEX tubing.

Installation Process and Ease

Copper tubing requires soldering, bending, and precise fitting, making the installation process labor-intensive and demanding specialized tools and skills. PEX tubing is flexible, easily cut, and joined with simple crimp or push-fit fittings, significantly reducing installation time and complexity. The ease of PEX installation often results in lower labor costs and faster project completion compared to copper tubing.

Cost Analysis: Copper vs PEX

Copper tubing typically costs between $2 and $4 per linear foot, making it more expensive upfront than PEX tubing, which ranges from $0.50 to $2 per linear foot. Installation costs for copper are elevated due to the need for specialized tools and soldering, whereas PEX installation is faster and requires fewer tools, lowering labor expenses significantly. Over time, PEX offers better cost efficiency in both material and labor, but copper's durability can justify higher initial investment in certain applications.

Corrosion and Chemical Resistance

Copper tubing exhibits excellent corrosion resistance in most water systems, resisting bacteria growth and maintaining structural integrity over time. PEX tubing offers superior chemical resistance, particularly against acidic or alkaline solutions, preventing degradation and extending lifespan in challenging environments. Both materials provide durability, but copper is prone to corrosion in highly acidic water, while PEX remains unaffected by most chemicals.

Flexibility and Versatility

Copper tubing offers limited flexibility compared to PEX tubing, which can bend easily around corners and obstacles without the need for fittings. PEX tubing's adaptability allows for quicker installation and fewer leak points, making it ideal for complex plumbing layouts. Copper is rigid and requires soldering or mechanical connections, reducing its versatility in various plumbing applications.

Water Quality and Health Concerns

Copper tubing offers natural antimicrobial properties that inhibit bacterial growth, ensuring higher water quality and reducing health risks. PEX tubing, made from cross-linked polyethylene, may leach trace chemicals over time but is generally certified safe for potable water; however, it lacks inherent antimicrobial benefits. Studies indicate that copper's ability to maintain a more sterile water environment gives it an edge in health safety compared to PEX, especially in long-term water storage scenarios.

Maintenance and Repair Considerations

Copper tubing offers durability with resistance to UV light and can withstand high temperatures, requiring minimal maintenance and straightforward repair using soldering techniques. PEX tubing, made from flexible plastic, demands less frequent repairs due to its resistance to scale and chlorine but requires specialized fittings and tools for repairs, which may complicate maintenance. Choosing between copper and PEX tubing involves weighing the ease and cost of repairs against the material's long-term performance in different plumbing environments.

Best Applications for Copper and PEX Tubing

Copper tubing excels in applications requiring durability, corrosion resistance, and high-temperature tolerance, making it ideal for hot water supply lines and HVAC systems. PEX tubing offers superior flexibility, ease of installation, and resistance to scale and chlorine, which is advantageous for radiant floor heating and cold water distribution. Both materials serve distinct purposes, with copper preferred for longevity and heat resistance, while PEX is favored for cost-effective, flexible plumbing solutions.

Copper Tubing vs PEX Tubing Infographic

materialdif.com

materialdif.com