Copper mining involves extracting ore from the earth, which requires significant energy consumption and environmental disruption, including habitat destruction and soil erosion. Copper recycling significantly reduces environmental impact by conserving natural resources, decreasing energy use by up to 85%, and minimizing greenhouse gas emissions compared to mining. The growing emphasis on sustainable practices highlights recycling as a more eco-friendly and cost-effective method to meet global copper demand.

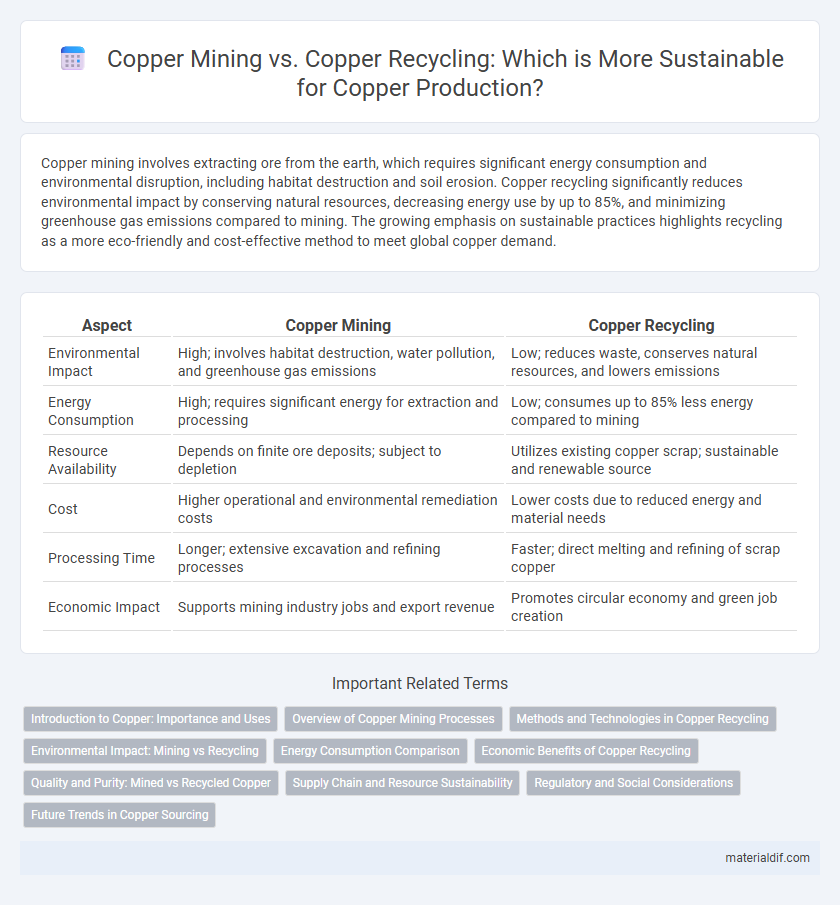

Table of Comparison

| Aspect | Copper Mining | Copper Recycling |

|---|---|---|

| Environmental Impact | High; involves habitat destruction, water pollution, and greenhouse gas emissions | Low; reduces waste, conserves natural resources, and lowers emissions |

| Energy Consumption | High; requires significant energy for extraction and processing | Low; consumes up to 85% less energy compared to mining |

| Resource Availability | Depends on finite ore deposits; subject to depletion | Utilizes existing copper scrap; sustainable and renewable source |

| Cost | Higher operational and environmental remediation costs | Lower costs due to reduced energy and material needs |

| Processing Time | Longer; extensive excavation and refining processes | Faster; direct melting and refining of scrap copper |

| Economic Impact | Supports mining industry jobs and export revenue | Promotes circular economy and green job creation |

Introduction to Copper: Importance and Uses

Copper is a vital metal extensively used in electrical wiring, plumbing, and electronics due to its excellent conductivity and corrosion resistance. Copper mining involves extracting copper ores from the earth, providing a primary source of raw material for industrial applications. Recycling copper significantly reduces environmental impact and energy consumption, making it a sustainable alternative in meeting global copper demand.

Overview of Copper Mining Processes

Copper mining involves extracting copper ore from open pits or underground mines followed by crushing, grinding, and flotation to concentrate the copper minerals. This ore concentrate undergoes smelting and refining to produce pure copper metal suitable for industrial use. Mining operations require extensive energy inputs and can have significant environmental impacts compared to copper recycling processes, which recover copper from scrap materials with less energy consumption.

Methods and Technologies in Copper Recycling

Copper recycling employs advanced methods such as hydrometallurgical processing and pyrometallurgical techniques that significantly reduce energy consumption compared to traditional copper mining. Technologies like solvent extraction and electrowinning enhance the recovery of high-purity copper from recycled materials, optimizing resource efficiency. These innovative recycling processes lower environmental impacts and conserve natural copper ore reserves while maintaining metal quality.

Environmental Impact: Mining vs Recycling

Copper mining generates significant environmental impacts including habitat destruction, soil erosion, and high energy consumption, leading to substantial carbon emissions and water pollution from tailings and acid mine drainage. Conversely, copper recycling drastically reduces environmental harm by lowering energy usage by up to 85%, decreasing greenhouse gas emissions, and minimizing the need for harmful mining processes. Recycling copper conserves natural resources and reduces the environmental footprint, making it a more sustainable approach compared to traditional mining methods.

Energy Consumption Comparison

Copper recycling consumes up to 85% less energy compared to primary copper mining, significantly reducing carbon emissions and environmental impact. Mining requires intensive processes like ore extraction, crushing, and smelting, which involve high energy consumption from fossil fuels. Recycling copper scrap involves melting and refining, which demand substantially lower energy input, making it a more sustainable and cost-effective option for meeting global copper demand.

Economic Benefits of Copper Recycling

Copper recycling significantly reduces production costs by requiring up to 85% less energy compared to copper mining, leading to lower operational expenses and increased profitability. Recycled copper's shorter supply chain decreases transportation and processing costs, enhancing economic efficiency in the copper market. This sustainable approach also fosters job creation in recycling industries, contributing positively to local economies while conserving natural resources.

Quality and Purity: Mined vs Recycled Copper

Copper mining produces high-purity copper typically above 99.9%, which is essential for electrical and industrial applications demanding superior conductivity and strength. Recycled copper may contain impurities from alloying elements or contaminants, often requiring additional refining to meet quality standards comparable to freshly mined copper. Advances in recycling technology have significantly improved the purity of recycled copper, making it a sustainable alternative without compromising material performance.

Supply Chain and Resource Sustainability

Copper mining primarily relies on extraction from ore deposits, involving extensive supply chain activities such as mining operations, ore transportation, and smelting processes, which contribute to significant environmental impacts and resource depletion. Copper recycling reduces dependency on primary mining by recovering valuable metals from scrap, minimizing energy consumption by up to 85%, and streamlining supply chains through shorter material loops and reduced logistical requirements. Emphasizing copper recycling enhances resource sustainability by conserving natural ore reserves, lowering greenhouse gas emissions, and promoting circular economy practices within the global copper industry.

Regulatory and Social Considerations

Copper mining faces stringent regulatory frameworks aimed at minimizing environmental impacts, such as habitat disruption and water contamination, often requiring extensive environmental impact assessments and community consultations. Copper recycling benefits from less regulatory complexity, fostering socially responsible practices by reducing waste and conserving natural resources, which aligns with growing consumer and governmental demands for sustainable sourcing. Both sectors must navigate evolving policies and social expectations, with mining industries increasingly investing in community development and recycling operations emphasizing transparency and ethical supply chains.

Future Trends in Copper Sourcing

Future trends in copper sourcing emphasize increased recycling rates to reduce environmental impact and conserve ore reserves. Technological advancements in copper mining focus on automation and digitalization to improve efficiency and reduce operational costs. The integration of circular economy principles drives investments toward urban mining and secondary copper production to meet growing global demand sustainably.

Copper Mining vs Copper Recycling Infographic

materialdif.com

materialdif.com