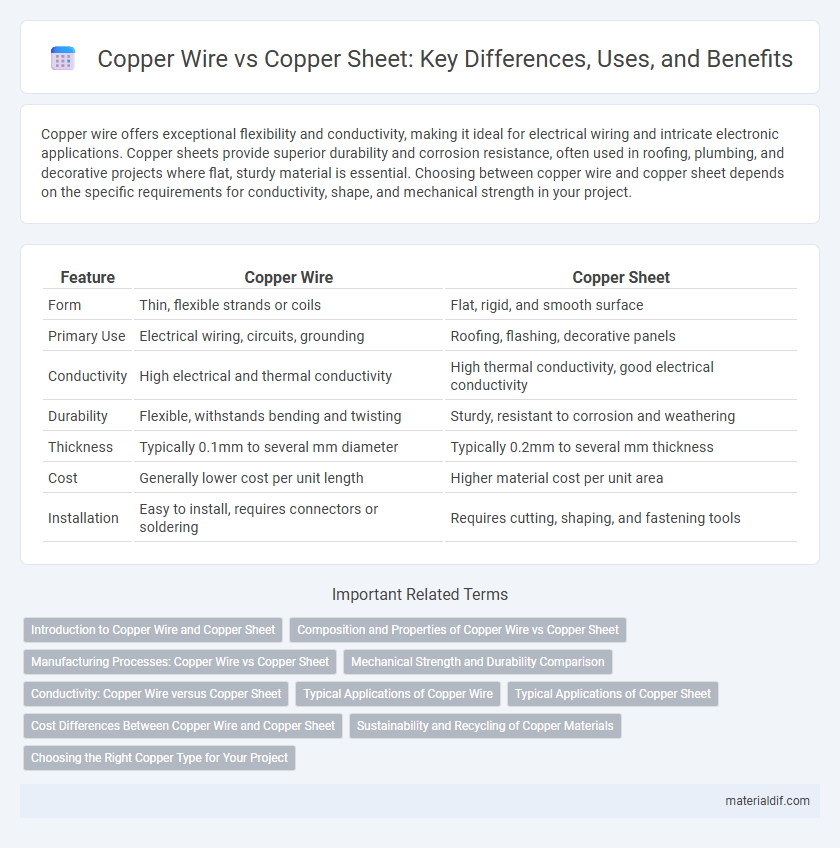

Copper wire offers exceptional flexibility and conductivity, making it ideal for electrical wiring and intricate electronic applications. Copper sheets provide superior durability and corrosion resistance, often used in roofing, plumbing, and decorative projects where flat, sturdy material is essential. Choosing between copper wire and copper sheet depends on the specific requirements for conductivity, shape, and mechanical strength in your project.

Table of Comparison

| Feature | Copper Wire | Copper Sheet |

|---|---|---|

| Form | Thin, flexible strands or coils | Flat, rigid, and smooth surface |

| Primary Use | Electrical wiring, circuits, grounding | Roofing, flashing, decorative panels |

| Conductivity | High electrical and thermal conductivity | High thermal conductivity, good electrical conductivity |

| Durability | Flexible, withstands bending and twisting | Sturdy, resistant to corrosion and weathering |

| Thickness | Typically 0.1mm to several mm diameter | Typically 0.2mm to several mm thickness |

| Cost | Generally lower cost per unit length | Higher material cost per unit area |

| Installation | Easy to install, requires connectors or soldering | Requires cutting, shaping, and fastening tools |

Introduction to Copper Wire and Copper Sheet

Copper wire, renowned for its exceptional electrical conductivity, is essential in electrical wiring, telecommunications, and electronics due to its flexibility and tensile strength. Copper sheet, characterized by its flat, malleable form, serves critical roles in roofing, automotive parts, and industrial applications where durability and corrosion resistance are paramount. Both copper wire and copper sheet showcase copper's versatility, catering to distinct functional requirements in various industries.

Composition and Properties of Copper Wire vs Copper Sheet

Copper wire and copper sheet both predominantly consist of high-purity copper, typically above 99.9%, ensuring excellent electrical conductivity and corrosion resistance. Copper wire is drawn into fine strands to enhance flexibility and tensile strength, making it suitable for electrical applications, while copper sheet undergoes rolling processes that maintain its malleability and surface uniformity for use in roofing, cladding, and fabrication. The distinct mechanical properties arise from their forms: copper wire exhibits higher ductility and tensile strength due to cold working, whereas copper sheet offers superior surface smoothness and structural rigidity.

Manufacturing Processes: Copper Wire vs Copper Sheet

Copper wire manufacturing involves drawing copper billets through a series of dies to reduce diameter and increase length, ensuring high tensile strength and conductivity. Copper sheet production utilizes continuous casting followed by rolling and annealing processes to achieve uniform thickness and smooth surface finish, suited for roofing and electrical applications. Both processes emphasize precise temperature control and quality assurance to optimize the copper's physical properties for industrial use.

Mechanical Strength and Durability Comparison

Copper wire exhibits higher tensile strength and flexibility compared to copper sheets, making it ideal for applications requiring mechanical endurance under bending and twisting stresses. Copper sheets provide superior compressive strength and resistance to impact, supporting structural stability in flat or rigid formations. Durability-wise, copper wire withstands cyclic loading better due to its ductility, while copper sheets resist corrosion and wear more effectively in exposed environments.

Conductivity: Copper Wire versus Copper Sheet

Copper wire exhibits superior electrical conductivity due to its elongated structure that minimizes resistance and enhances electron flow, making it ideal for electrical transmission. Copper sheets offer slightly lower conductivity compared to wires because their flat surface and greater cross-sectional area can introduce minor resistance variations. Both forms maintain excellent conductivity inherent to copper, but wire's geometry optimizes performance in applications requiring efficient current flow.

Typical Applications of Copper Wire

Copper wire is primarily used in electrical wiring due to its excellent conductivity and flexibility, making it essential for power transmission, telecommunications, and electronics. It is commonly found in household wiring, circuit boards, and motor windings where efficient current flow and durability are crucial. Copper wire also serves in grounding systems and electromagnetic applications, leveraging its corrosion resistance and tensile strength.

Typical Applications of Copper Sheet

Copper sheet is widely used in roofing, flashing, and architectural cladding due to its durability, corrosion resistance, and aesthetic appeal. It also finds applications in electrical components, heat exchangers, and industrial machinery where flat, malleable copper surfaces are required. Unlike copper wire that excels in conductivity for electrical wiring, copper sheets provide structural support and protective barriers in construction and manufacturing.

Cost Differences Between Copper Wire and Copper Sheet

Copper wire generally costs more per pound than copper sheet due to the additional manufacturing processes such as drawing and annealing required to achieve its shape and flexibility. Copper sheets, produced by rolling, are less labor-intensive and often available at lower prices, making them a cost-effective choice for applications needing flat or embossed metal. Market prices for copper fluctuate based on purity, thickness, and market demand, but the complexity of wire production typically drives its higher cost compared to copper sheets.

Sustainability and Recycling of Copper Materials

Copper wire offers higher recycling efficiency due to its continuous, uniform shape, enabling easier separation and remelting compared to copper sheets, which often contain coatings or laminates that complicate recycling. The sustainability of copper materials is enhanced by copper wire's longer lifecycle and superior conductivity, reducing energy consumption in electrical applications. Both forms benefit from copper's inherent recyclability, as recycled copper retains full conductivity without degradation, minimizing the need for newly mined copper and associated environmental impacts.

Choosing the Right Copper Type for Your Project

Copper wire offers excellent flexibility and conductivity, making it ideal for electrical wiring and intricate crafting projects. Copper sheets provide superior strength and durability, perfect for roofing, flashing, and sculptural work requiring rigid material. Selecting the right copper type depends on the project's specific electrical, mechanical, and aesthetic requirements to maximize performance and longevity.

Copper Wire vs Copper Sheet Infographic

materialdif.com

materialdif.com