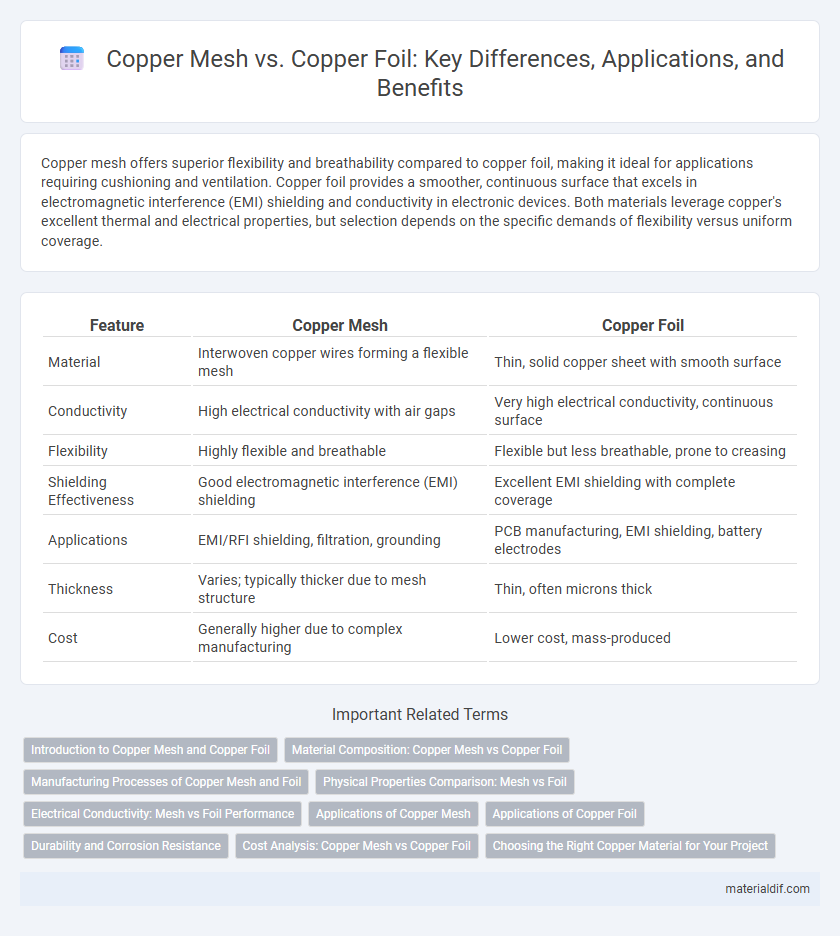

Copper mesh offers superior flexibility and breathability compared to copper foil, making it ideal for applications requiring cushioning and ventilation. Copper foil provides a smoother, continuous surface that excels in electromagnetic interference (EMI) shielding and conductivity in electronic devices. Both materials leverage copper's excellent thermal and electrical properties, but selection depends on the specific demands of flexibility versus uniform coverage.

Table of Comparison

| Feature | Copper Mesh | Copper Foil |

|---|---|---|

| Material | Interwoven copper wires forming a flexible mesh | Thin, solid copper sheet with smooth surface |

| Conductivity | High electrical conductivity with air gaps | Very high electrical conductivity, continuous surface |

| Flexibility | Highly flexible and breathable | Flexible but less breathable, prone to creasing |

| Shielding Effectiveness | Good electromagnetic interference (EMI) shielding | Excellent EMI shielding with complete coverage |

| Applications | EMI/RFI shielding, filtration, grounding | PCB manufacturing, EMI shielding, battery electrodes |

| Thickness | Varies; typically thicker due to mesh structure | Thin, often microns thick |

| Cost | Generally higher due to complex manufacturing | Lower cost, mass-produced |

Introduction to Copper Mesh and Copper Foil

Copper mesh features a woven or knitted grid of fine copper wires, offering high flexibility and breathability ideal for electromagnetic shielding and grounding applications. Copper foil is a thin, solid sheet of copper providing excellent conductivity and a smooth surface, commonly used in printed circuit boards and EMI shielding. Both forms leverage copper's superior electrical and thermal properties but serve distinct roles based on their structural composition and application requirements.

Material Composition: Copper Mesh vs Copper Foil

Copper mesh consists of woven or knitted strands of pure copper, creating a flexible, breathable structure ideal for electromagnetic interference (EMI) shielding and filtration. Copper foil is made from thin sheets of highly conductive copper, offering uniform thickness and smooth surfaces suited for printed circuit boards (PCBs) and heat dissipation applications. Both materials utilize high-purity copper but differ significantly in form and mechanical properties, influencing their specific industrial uses.

Manufacturing Processes of Copper Mesh and Foil

Copper mesh is manufactured by weaving fine copper wires into a grid-like pattern, providing flexibility and breathability ideal for filtration and shielding applications. Copper foil is produced through a rolling process that compresses copper slabs into thin, uniform sheets with high conductivity and smooth surface finish, commonly used in electronics and batteries. Both processes require precise control of temperature and mechanical forces to achieve desired thickness, strength, and electrical properties.

Physical Properties Comparison: Mesh vs Foil

Copper mesh exhibits a porous, flexible structure with better ventilation and higher tensile strength, making it ideal for electromagnetic interference (EMI) shielding and filtration applications. Copper foil offers a smooth, continuous surface with uniform thickness and excellent conductivity, suited for printed circuit boards (PCBs) and thermal management. The mesh's physical properties allow for airflow and mechanical durability, while copper foil provides superior surface contact and electrical performance.

Electrical Conductivity: Mesh vs Foil Performance

Copper mesh offers enhanced electrical conductivity due to its three-dimensional structure, which allows better airflow and heat dissipation compared to copper foil. Copper foil, while providing a uniform and continuous conductive surface, may experience slightly higher resistance because of its thin and flat form factor. For applications demanding efficient current flow and thermal management, copper mesh often outperforms foil in maintaining stable electrical conductivity.

Applications of Copper Mesh

Copper mesh is widely used in electromagnetic interference (EMI) shielding for electronic devices due to its excellent conductivity and flexibility, allowing it to conform to irregular surfaces. Its porous structure makes it ideal for filtration and ventilation in industrial applications, effectively blocking contaminants while maintaining airflow. Copper mesh also finds applications in architectural design for decorative and functional purposes, benefiting from its corrosion resistance and aesthetic appeal.

Applications of Copper Foil

Copper foil is widely used in flexible printed circuit boards (FPCBs), electromagnetic interference (EMI) shielding, and lithium-ion battery electrodes due to its excellent conductivity and malleability. Its thin, uniform thickness allows precise layering in microelectronics and advanced packaging technologies. Copper foil's superior heat dissipation and corrosion resistance make it ideal for power electronics and automotive applications where durability is crucial.

Durability and Corrosion Resistance

Copper mesh offers enhanced durability due to its woven structure, which provides flexibility and resistance to wear under physical stress. Copper foil, while thinner and less robust, excels in corrosion resistance because of its smooth surface that minimizes exposure to environmental elements. Both materials resist oxidation effectively, but copper mesh is preferred in applications requiring mechanical resilience, whereas copper foil suits environments demanding superior corrosion protection.

Cost Analysis: Copper Mesh vs Copper Foil

Copper mesh generally incurs higher initial costs compared to copper foil due to its complex manufacturing process and material density. Copper foil offers a more cost-effective solution for large-scale applications with its thinner gauge and easier production methods, reducing raw material usage and waste. When evaluating projects with budget constraints, copper foil provides significant savings in material costs and handling, while copper mesh justifies its expense through enhanced durability and mechanical stability.

Choosing the Right Copper Material for Your Project

Copper mesh offers superior flexibility and breathability, making it ideal for applications requiring ventilation or filtration, while copper foil provides a smooth, conductive surface preferred in electronics and shielding projects. When choosing between copper mesh and copper foil, consider factors such as conductivity, flexibility, thickness, and the specific demands of your project environment. Copper foil typically excels in electromagnetic interference (EMI) shielding, whereas copper mesh is favored for grounding and static dissipation due to its porous structure.

Copper Mesh vs Copper Foil Infographic

materialdif.com

materialdif.com