C11000 copper, also known as electrolytic tough pitch (ETP) copper, contains a small amount of oxygen, enhancing its electrical conductivity and making it ideal for electrical wiring and components. In contrast, C10100 copper is oxygen-free, offering superior ductility and corrosion resistance, which is crucial for applications requiring high purity and strength. Both types serve distinct purposes, with C11000 favored for electrical applications and C10100 preferred in environments demanding greater material integrity.

Table of Comparison

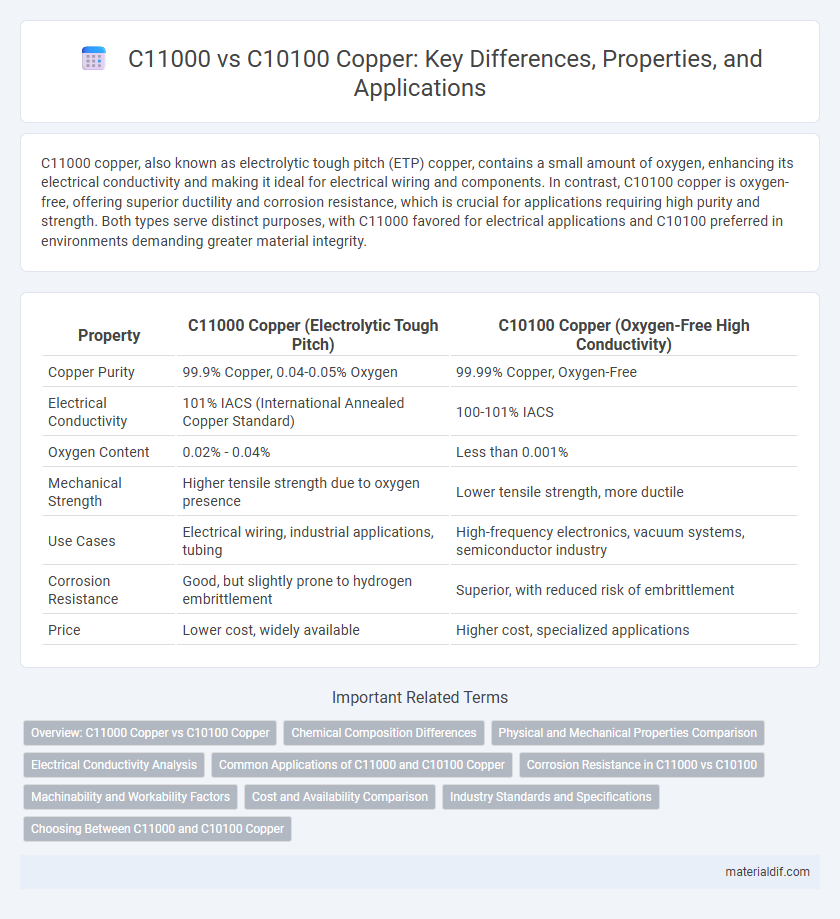

| Property | C11000 Copper (Electrolytic Tough Pitch) | C10100 Copper (Oxygen-Free High Conductivity) |

|---|---|---|

| Copper Purity | 99.9% Copper, 0.04-0.05% Oxygen | 99.99% Copper, Oxygen-Free |

| Electrical Conductivity | 101% IACS (International Annealed Copper Standard) | 100-101% IACS |

| Oxygen Content | 0.02% - 0.04% | Less than 0.001% |

| Mechanical Strength | Higher tensile strength due to oxygen presence | Lower tensile strength, more ductile |

| Use Cases | Electrical wiring, industrial applications, tubing | High-frequency electronics, vacuum systems, semiconductor industry |

| Corrosion Resistance | Good, but slightly prone to hydrogen embrittlement | Superior, with reduced risk of embrittlement |

| Price | Lower cost, widely available | Higher cost, specialized applications |

Overview: C11000 Copper vs C10100 Copper

C11000 copper, also known as electrolytic tough pitch (ETP) copper, offers excellent electrical conductivity of approximately 101% IACS and is widely used in electrical wiring and components. C10100 copper, or oxygen-free electronic (OFE) copper, provides higher purity with over 99.99% copper content, resulting in superior electrical and thermal conductivity ideal for high-performance electronic applications. Both alloys serve distinct purposes, with C11000 preferred for cost-effective electrical solutions and C10100 used in scenarios demanding maximum conductivity and minimal impurities.

Chemical Composition Differences

C11000 copper, known as electrolytic tough pitch (ETP) copper, contains approximately 99.9% pure copper with oxygen levels around 0.02% to 0.04%, enhancing electrical conductivity and forming copper oxide inclusions. In contrast, C10100 copper, or oxygen-free electronic (OFE) copper, maintains an even higher purity level of 99.99% copper with oxygen content less than 0.0005%, which prevents oxide formation and offers superior ductility and corrosion resistance. The key chemical composition differences lie in oxygen content and purity, influencing physical properties critical in electrical and electronic applications.

Physical and Mechanical Properties Comparison

C11000 copper, also known as electrolytic tough pitch (ETP) copper, contains oxygen around 0.02-0.04%, resulting in higher electrical conductivity up to 100% IACS and tensile strength typically between 210-240 MPa. C10100 copper, or oxygen-free copper (OFC), has oxygen content less than 0.001%, offering superior ductility and thermal conductivity slightly above 101% IACS, along with tensile strength around 220 MPa. The mechanical properties show C10100 with enhanced cold working ability and corrosion resistance, while C11000 excels in cost-effective electrical applications requiring high conductivity but lower mechanical performance.

Electrical Conductivity Analysis

C11000 copper, known as electrolytic tough pitch (ETP) copper, typically exhibits electrical conductivity around 101% IACS (International Annealed Copper Standard), making it ideal for electrical applications requiring excellent conductivity. In contrast, C10100 copper, also called oxygen-free copper (OFC), offers slightly higher purity and can reach conductivity levels above 100% IACS with reduced oxygen content, enhancing performance in high-frequency or sensitive electronic components. The minimal oxygen presence in C10100 copper reduces the risk of hydrogen embrittlement and improves conductivity stability, especially under thermal cycling conditions.

Common Applications of C11000 and C10100 Copper

C11000 copper, known as electrolytic tough pitch (ETP) copper, is commonly used in electrical wiring, busbars, and motor windings due to its excellent electrical conductivity and machinability. C10100 copper, or oxygen-free high conductivity (OFHC) copper, is preferred in high-performance electrical and electronic applications such as vacuum tubes, semiconductors, and cryogenics, where superior purity and minimal oxygen content are critical. Both grades serve crucial roles in the electrical industry, with C11000 favored for general-purpose conductors and C10100 specialized for environments demanding enhanced conductivity and corrosion resistance.

Corrosion Resistance in C11000 vs C10100

C11000 copper, also known as Electrolytic Tough Pitch (ETP) copper, contains oxygen levels around 0.02%-0.05%, which enhances its corrosion resistance compared to C10100 copper, a High-Purity Oxygen-Free Copper with oxygen levels below 0.001%. The presence of oxygen in C11000 improves its resistance to atmospheric corrosion and stress-corrosion cracking, making it suitable for electrical and architectural applications where durability is critical. C10100 copper offers superior electrical conductivity but is more prone to dezincification and certain corrosive environments due to its minimal oxygen content.

Machinability and Workability Factors

C11000 copper, containing 99.9% pure copper, exhibits excellent machinability due to its moderate strength and softness, making it ideal for precision machining and intricate components. In contrast, C10100 copper, also known as electrolytic tough pitch (ETP) copper, offers superior electrical conductivity but lower machinability due to higher purity and reduced silicon content, resulting in increased ductility but less ease in cutting operations. Workability in C11000 allows for better forming and shaping with less risk of cracking, while C10100 is preferred for applications requiring high conductivity and thermal performance despite slightly more challenging machining processes.

Cost and Availability Comparison

C11000 copper, also known as electrolytic tough pitch (ETP) copper, is generally more affordable and widely available compared to C10100 copper, which is oxygen-free high conductivity (OFHC) copper with higher purity. The increased purity of C10100 copper results in higher production costs and limited supply, making it more expensive and less readily obtainable. For applications where cost efficiency and standard conductivity are priorities, C11000 copper is the preferred choice due to its balance of price and availability.

Industry Standards and Specifications

C11000 copper, known as Electrolytic Tough Pitch (ETP) copper, conforms to ASTM B187 and ASTM B170 industry standards, ensuring excellent electrical conductivity and strength for general electrical applications. C10100 copper, also called Oxygen-Free Electronic (OFE) copper, meets ASTM B170 and ASTM B241 specifications, offering superior purity with minimal oxygen content for enhanced thermal and electrical conductivity in high-reliability electronics. These differing standards reflect their typical industrial uses, with C11000 favored in power distribution and wiring, while C10100 is preferred in specialized electronic and aerospace components.

Choosing Between C11000 and C10100 Copper

Choosing between C11000 and C10100 copper depends on specific application requirements, where C11000 offers higher electrical conductivity around 101% IACS, making it ideal for electrical wiring and components needing excellent conductivity. C10100 copper, with a slightly lower conductivity near 100% IACS but superior corrosion resistance and mechanical strength, suits environments exposed to harsh conditions or where durability is critical. Cost considerations also influence the choice, as C11000 generally provides a more economical option for high-conductivity needs, while C10100 justifies its price premium through enhanced performance in challenging applications.

C11000 Copper vs C10100 Copper Infographic

materialdif.com

materialdif.com