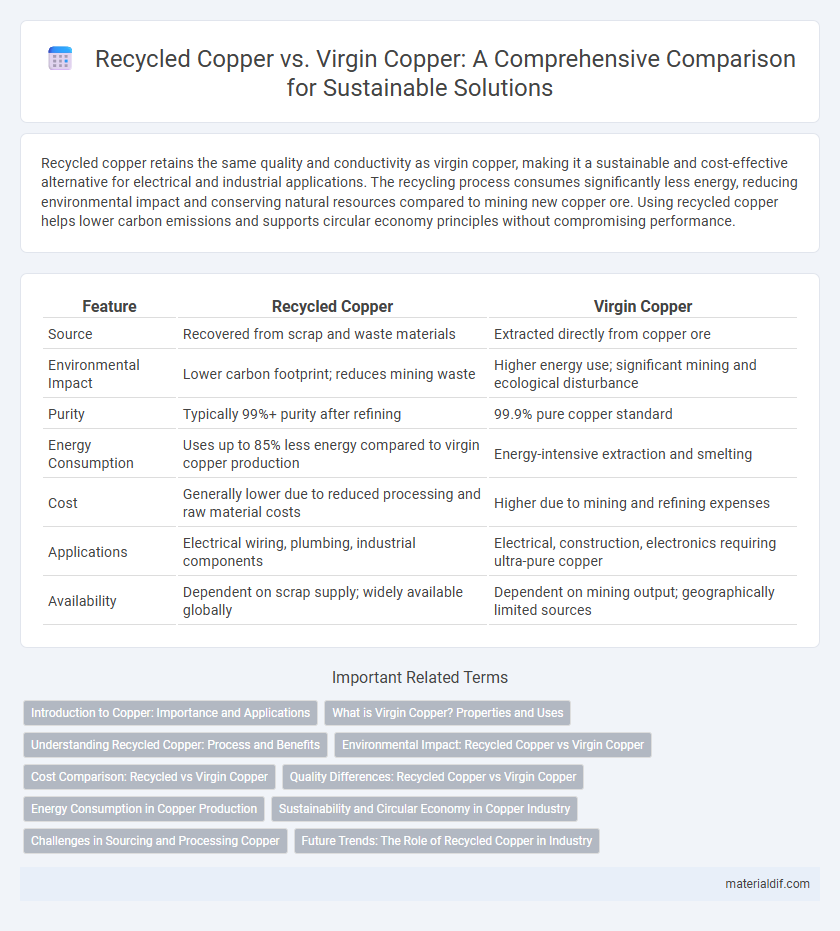

Recycled copper retains the same quality and conductivity as virgin copper, making it a sustainable and cost-effective alternative for electrical and industrial applications. The recycling process consumes significantly less energy, reducing environmental impact and conserving natural resources compared to mining new copper ore. Using recycled copper helps lower carbon emissions and supports circular economy principles without compromising performance.

Table of Comparison

| Feature | Recycled Copper | Virgin Copper |

|---|---|---|

| Source | Recovered from scrap and waste materials | Extracted directly from copper ore |

| Environmental Impact | Lower carbon footprint; reduces mining waste | Higher energy use; significant mining and ecological disturbance |

| Purity | Typically 99%+ purity after refining | 99.9% pure copper standard |

| Energy Consumption | Uses up to 85% less energy compared to virgin copper production | Energy-intensive extraction and smelting |

| Cost | Generally lower due to reduced processing and raw material costs | Higher due to mining and refining expenses |

| Applications | Electrical wiring, plumbing, industrial components | Electrical, construction, electronics requiring ultra-pure copper |

| Availability | Dependent on scrap supply; widely available globally | Dependent on mining output; geographically limited sources |

Introduction to Copper: Importance and Applications

Copper, a highly conductive metal, is essential in electrical wiring, plumbing, and renewable energy systems due to its excellent thermal and electrical properties. Recycled copper maintains the same quality as virgin copper, reducing energy consumption by up to 85% and minimizing environmental impact in manufacturing processes. The increasing demand for sustainable materials drives the preference for recycled copper across industries such as construction, electronics, and transportation.

What is Virgin Copper? Properties and Uses

Virgin copper refers to copper extracted directly from natural ore deposits through mining, offering high purity and superior conductivity critical in electrical wiring and electronics. This metal exhibits excellent malleability, corrosion resistance, and thermal conductivity, making it valuable in construction, plumbing, and industrial machinery. Compared to recycled copper, virgin copper provides consistent chemical composition and mechanical strength essential for high-performance applications.

Understanding Recycled Copper: Process and Benefits

Recycled copper undergoes a multi-step process involving collection, sorting, melting, and refining to restore its purity, making it nearly indistinguishable from virgin copper in quality and performance. This sustainable method significantly reduces energy consumption by up to 85% compared to extracting and processing virgin copper from ore, lowering environmental impact and greenhouse gas emissions. Utilizing recycled copper supports resource conservation, decreases waste in landfills, and promotes a circular economy within the copper industry.

Environmental Impact: Recycled Copper vs Virgin Copper

Recycled copper significantly reduces environmental impact by lowering energy consumption by up to 85% compared to virgin copper extraction, which involves extensive mining and smelting processes that release large amounts of greenhouse gases. The recycling process minimizes habitat destruction and conserves natural resources by reusing existing copper, thereby reducing mining waste and associated soil and water pollution. Utilizing recycled copper supports circular economy principles, decreasing the overall carbon footprint and contributing to sustainable metal supply chains.

Cost Comparison: Recycled vs Virgin Copper

Recycled copper typically costs 20-30% less than virgin copper due to lower energy consumption and reduced mining expenses. The price advantage of recycled copper is influenced by global scrap availability and market demand fluctuations. This cost efficiency makes recycled copper a preferred choice in industries aiming to reduce production expenses and environmental impact.

Quality Differences: Recycled Copper vs Virgin Copper

Recycled copper maintains nearly the same conductivity and strength levels as virgin copper, making it highly suitable for electrical and industrial applications. While virgin copper offers slightly higher purity, modern recycling processes effectively eliminate most contaminants, resulting in minimal quality differences. The choice between recycled and virgin copper depends largely on specific industry standards and environmental considerations rather than significant performance gaps.

Energy Consumption in Copper Production

Recycled copper requires up to 85% less energy compared to virgin copper production, significantly reducing the carbon footprint associated with copper manufacturing. The energy-intensive mining, smelting, and refining processes of virgin copper contribute to higher greenhouse gas emissions. Utilizing recycled copper enhances sustainability by conserving natural resources and minimizing environmental impact.

Sustainability and Circular Economy in Copper Industry

Recycled copper significantly reduces environmental impact by lowering energy consumption and decreasing mining waste compared to virgin copper extraction. Embracing recycled copper enhances sustainability by conserving natural resources and minimizing greenhouse gas emissions throughout the circular economy in the copper industry. Increasing the use of recycled copper supports closed-loop systems, promoting efficient resource utilization and extending the lifespan of copper materials.

Challenges in Sourcing and Processing Copper

Sourcing recycled copper faces challenges such as contamination from mixed metals and varying alloy compositions, which complicate sorting and refining processes. Virgin copper extraction involves extensive mining operations that demand significant energy consumption and generate environmental impacts like habitat disruption and tailings disposal. Both recycled and virgin copper processing require advanced technologies to maintain purity standards essential for high-performance applications in electronics and construction.

Future Trends: The Role of Recycled Copper in Industry

Recycled copper is projected to constitute over 40% of global copper supply by 2030, driven by increasing demand for sustainable materials in electrical and construction sectors. Advances in refining technologies are enhancing the quality of recycled copper, making it virtually indistinguishable from virgin copper and expanding its industrial applications. Industry trends emphasize circular economy models, with recycled copper playing a pivotal role in reducing carbon footprints and conserving natural resources.

Recycled Copper vs Virgin Copper Infographic

materialdif.com

materialdif.com