Lead-free copper offers superior environmental safety and compliance with modern regulations by eliminating toxic lead content, making it ideal for plumbing and potable water systems. Leaded copper, while historically favored for its machinability and corrosion resistance, poses health risks due to lead leaching, limiting its use in residential and food-related applications. Choosing lead-free copper ensures enhanced durability and safer water quality, aligning with sustainable building practices.

Table of Comparison

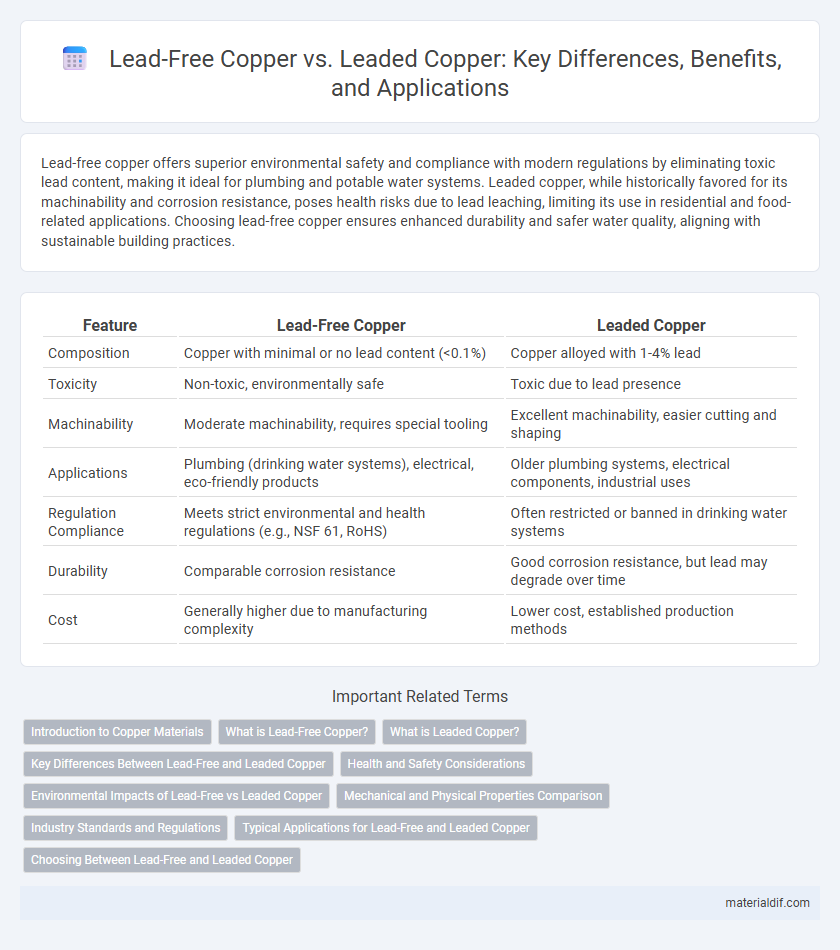

| Feature | Lead-Free Copper | Leaded Copper |

|---|---|---|

| Composition | Copper with minimal or no lead content (<0.1%) | Copper alloyed with 1-4% lead |

| Toxicity | Non-toxic, environmentally safe | Toxic due to lead presence |

| Machinability | Moderate machinability, requires special tooling | Excellent machinability, easier cutting and shaping |

| Applications | Plumbing (drinking water systems), electrical, eco-friendly products | Older plumbing systems, electrical components, industrial uses |

| Regulation Compliance | Meets strict environmental and health regulations (e.g., NSF 61, RoHS) | Often restricted or banned in drinking water systems |

| Durability | Comparable corrosion resistance | Good corrosion resistance, but lead may degrade over time |

| Cost | Generally higher due to manufacturing complexity | Lower cost, established production methods |

Introduction to Copper Materials

Lead-free copper offers enhanced environmental safety and improved conductivity compared to traditional leaded copper, which contains small amounts of lead to increase machinability. Lead-free variants are increasingly preferred in plumbing and electronic applications to meet stringent regulatory standards such as RoHS and reduce health risks associated with lead exposure. The shift to lead-free copper materials supports sustainable manufacturing while maintaining essential physical and chemical properties for industrial use.

What is Lead-Free Copper?

Lead-free copper is a type of copper alloy that contains little to no lead content, making it safer for applications requiring minimal toxicity, such as plumbing and potable water systems. This copper variant complies with stringent environmental and health regulations, reducing the risk of lead contamination in water supplies. Lead-free copper maintains excellent thermal and electrical conductivity while promoting healthier and more sustainable practices in manufacturing and construction.

What is Leaded Copper?

Leaded copper is an alloy composed primarily of copper with a small percentage of lead, typically ranging from 0.5% to 4%, added to improve machinability and ease of processing. This addition enhances chip formation during machining, reduces tool wear, and lowers manufacturing costs, making it ideal for components requiring precise shaping. Despite these advantages, leaded copper is less suitable for applications demanding high electrical conductivity or strict environmental compliance due to lead's toxic properties.

Key Differences Between Lead-Free and Leaded Copper

Lead-free copper contains minimal to no lead content, enhancing its environmental safety and compliance with strict regulations such as RoHS, while leaded copper includes lead to improve machinability and reduce tool wear. Leaded copper typically offers better mechanical properties for complex manufacturing processes but poses higher health and environmental risks due to lead toxicity. Key differences focus on composition, regulatory compliance, machinability, and environmental impact.

Health and Safety Considerations

Lead-free copper significantly reduces health risks linked to lead exposure, such as neurological damage and lead poisoning, making it safer for potable water systems. In contrast, leaded copper poses contamination hazards due to potential lead leaching, particularly in acidic or soft water environments. Regulatory standards like the Safe Drinking Water Act promote the use of lead-free copper to ensure safer water quality and protect public health.

Environmental Impacts of Lead-Free vs Leaded Copper

Lead-free copper significantly reduces environmental contamination risks compared to leaded copper, as it eliminates toxic lead leaching into soil and water systems during corrosion or disposal. Leaded copper components contribute to hazardous waste streams, increasing soil and groundwater pollution sources that threaten ecosystems and human health. Transitioning to lead-free copper supports safer recycling processes and aligns with global environmental regulations aimed at minimizing heavy metal pollution.

Mechanical and Physical Properties Comparison

Lead-free copper exhibits superior mechanical properties such as higher tensile strength and improved ductility compared to leaded copper, which contains small amounts of lead to enhance machinability but reduces overall structural integrity. Physically, lead-free copper offers better corrosion resistance and electrical conductivity, making it more suitable for applications requiring durability and efficient current flow. The absence of lead also aligns with environmental regulations, promoting safer recycling and reduced toxicity in end-use products.

Industry Standards and Regulations

Lead-free copper complies with stringent environmental regulations such as RoHS and REACH, which restrict lead content to reduce toxic exposure in plumbing and electrical applications. Industry standards like ASTM B16 and ISO 9459 specify lead content limits to ensure safety and performance, promoting wider adoption of lead-free alternatives in potable water systems. Leaded copper, although historically prevalent for its machinability, faces increasing phase-out due to health concerns and tightening regulatory frameworks worldwide.

Typical Applications for Lead-Free and Leaded Copper

Lead-free copper is typically used in plumbing systems, food and beverage processing equipment, and electrical wiring due to its superior environmental compliance and health safety standards. Leaded copper is often found in industrial applications, such as marine hardware, electrical connectors, and automotive components, where enhanced machinability and mechanical strength are required. Both types serve essential roles, with lead-free copper favored in potable water systems and leaded copper preferred in high-wear or corrosion-resistant environments.

Choosing Between Lead-Free and Leaded Copper

Choosing between lead-free and leaded copper depends on the application's regulatory requirements and environmental considerations. Lead-free copper offers improved safety and compliance with stringent health standards, making it ideal for plumbing and drinking water systems. Leaded copper, while easier to machine and often more cost-effective, is increasingly restricted due to lead's toxicity and environmental impact.

Lead-Free Copper vs Leaded Copper Infographic

materialdif.com

materialdif.com