Copper wire offers superior flexibility and conductivity, making it ideal for electrical wiring and precise connections. Copper strips provide enhanced durability and a larger surface area, which benefits grounding, shielding, and structural applications. Choosing between copper wire and copper strip depends on the specific conductivity, flexibility, and mechanical strength requirements of the project.

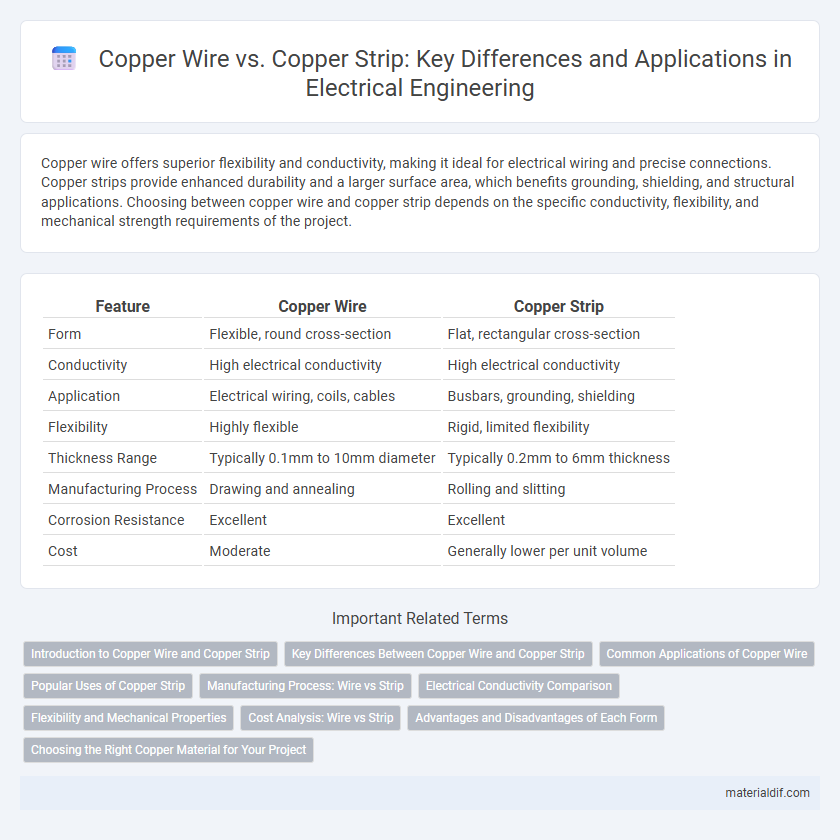

Table of Comparison

| Feature | Copper Wire | Copper Strip |

|---|---|---|

| Form | Flexible, round cross-section | Flat, rectangular cross-section |

| Conductivity | High electrical conductivity | High electrical conductivity |

| Application | Electrical wiring, coils, cables | Busbars, grounding, shielding |

| Flexibility | Highly flexible | Rigid, limited flexibility |

| Thickness Range | Typically 0.1mm to 10mm diameter | Typically 0.2mm to 6mm thickness |

| Manufacturing Process | Drawing and annealing | Rolling and slitting |

| Corrosion Resistance | Excellent | Excellent |

| Cost | Moderate | Generally lower per unit volume |

Introduction to Copper Wire and Copper Strip

Copper wire consists of thin, flexible strands of copper used primarily in electrical wiring due to its excellent conductivity and durability. Copper strips are flat, rectangular pieces of copper commonly utilized in applications requiring structural strength and efficient current distribution, such as electrical busbars and grounding. Both forms leverage copper's high thermal and electrical conductivity but differ in shape and specific industrial uses.

Key Differences Between Copper Wire and Copper Strip

Copper wire is typically cylindrical and highly flexible, designed for efficient electrical conductivity in wiring applications, while copper strip is flat, offering greater surface area for heat dissipation and mechanical strength in industrial uses. The diameter of copper wire ranges from very thin gauges for electronics to thicker sizes for power transmission, whereas copper strips vary in width and thickness tailored for busbars, connectors, and grounding systems. Electrical resistance, flexibility, and application environment serve as key differentiators, with copper wire excelling in versatility and copper strip favored for structural and thermal performance.

Common Applications of Copper Wire

Copper wire is widely used in electrical wiring for residential, commercial, and industrial applications due to its excellent conductivity and flexibility. It is essential in power transmission, telecommunications, and electronic devices, enabling efficient signal and power transfer. Copper wire also plays a crucial role in winding for motors, transformers, and electromagnets, where precise conductivity and durability are required.

Popular Uses of Copper Strip

Copper strips are widely used in electrical grounding, transformer windings, and busbar applications due to their excellent conductivity and flexibility. Their flat, thin shape makes them ideal for applications requiring tight spaces and precise electrical paths, unlike copper wire which is typically round and used for general wiring. Copper strips also find common use in electromagnetic shielding and circuit board connections due to their durability and corrosion resistance.

Manufacturing Process: Wire vs Strip

Copper wire manufacturing involves continuous drawing of copper rods through dies to reduce diameter and increase length, ensuring high tensile strength and flexibility. Copper strip production utilizes hot rolling or cold rolling processes, where copper slabs are passed through rollers to achieve a flat, thin, and wide shape suitable for electrical and industrial applications. Precision control in wire drawing ensures uniform conductivity, while strip rolling emphasizes surface finish and dimensional accuracy for lamination and circuitry uses.

Electrical Conductivity Comparison

Copper wire offers superior electrical conductivity due to its cylindrical shape, which allows electrons to flow with minimal resistance, making it ideal for high-current applications. Copper strip, while still conductive, has a larger surface area that can increase resistance slightly and is often used where mechanical strength and heat dissipation are prioritized over maximum conductivity. The choice between copper wire and copper strip depends on balancing electrical performance with physical requirements in electrical and electronic components.

Flexibility and Mechanical Properties

Copper wire exhibits high flexibility due to its slender, round cross-section, making it ideal for applications requiring frequent bending and twisting without breaking. In contrast, copper strips offer superior mechanical strength and rigidity, providing enhanced durability and resistance to deformation under mechanical stress. The choice between copper wire and copper strip depends on balancing flexibility needs against mechanical stability in electrical and industrial applications.

Cost Analysis: Wire vs Strip

Copper wire typically incurs higher manufacturing costs due to the specialized processes required for drawing and insulating, whereas copper strip production benefits from simpler rolling and cutting techniques, resulting in lower expenses. The price difference is also influenced by material thickness and application-specific requirements, with strips often offering cost efficiency in larger, flat conductive components. In industrial settings, choosing copper strip over wire can reduce overall project costs when electrical conductivity and mechanical strength meet design specifications.

Advantages and Disadvantages of Each Form

Copper wire offers superior flexibility and ease of installation, making it ideal for intricate electrical applications, while its high conductivity ensures efficient power transmission. Copper strip provides enhanced mechanical strength and better heat dissipation, suited for busbars and grounding systems, but its rigidity limits use in complex wiring layouts. The choice between copper wire and copper strip depends on specific needs for flexibility versus structural durability in electrical and industrial settings.

Choosing the Right Copper Material for Your Project

Copper wire offers superior flexibility and conductivity, making it ideal for electrical wiring, telecommunications, and intricate coil designs. Copper strips provide enhanced durability and surface area, suitable for grounding, bus bars, and structural applications where stability is critical. Selecting the right copper material depends on project requirements such as current capacity, mechanical strength, and installation environment.

Copper Wire vs Copper Strip Infographic

materialdif.com

materialdif.com