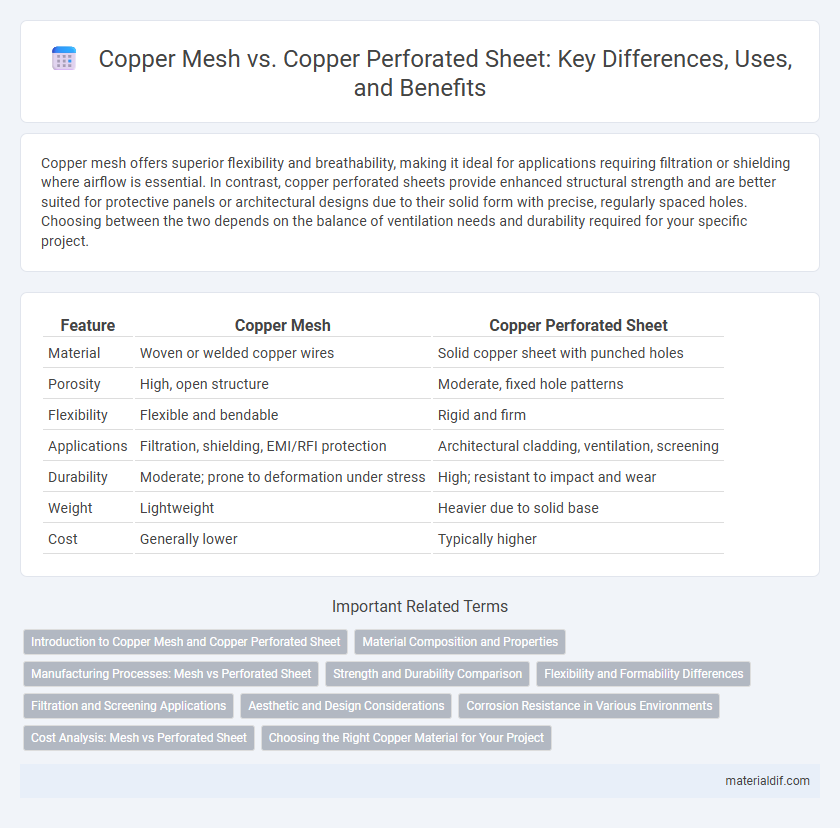

Copper mesh offers superior flexibility and breathability, making it ideal for applications requiring filtration or shielding where airflow is essential. In contrast, copper perforated sheets provide enhanced structural strength and are better suited for protective panels or architectural designs due to their solid form with precise, regularly spaced holes. Choosing between the two depends on the balance of ventilation needs and durability required for your specific project.

Table of Comparison

| Feature | Copper Mesh | Copper Perforated Sheet |

|---|---|---|

| Material | Woven or welded copper wires | Solid copper sheet with punched holes |

| Porosity | High, open structure | Moderate, fixed hole patterns |

| Flexibility | Flexible and bendable | Rigid and firm |

| Applications | Filtration, shielding, EMI/RFI protection | Architectural cladding, ventilation, screening |

| Durability | Moderate; prone to deformation under stress | High; resistant to impact and wear |

| Weight | Lightweight | Heavier due to solid base |

| Cost | Generally lower | Typically higher |

Introduction to Copper Mesh and Copper Perforated Sheet

Copper mesh consists of finely woven copper wires forming a flexible, breathable material ideal for electromagnetic shielding, filtration, and crafting applications. Copper perforated sheets are solid copper panels with precise, uniform holes punched to allow airflow, light passage, or drainage while maintaining structural integrity. Both materials leverage copper's high conductivity, corrosion resistance, and antimicrobial properties but serve distinct industrial and architectural functions based on their differing forms.

Material Composition and Properties

Copper mesh is composed of fine copper wires woven or knitted together, offering high flexibility, excellent electrical conductivity, and enhanced surface area for filtration and shielding applications. In contrast, copper perforated sheets are solid copper plates mechanically punched with uniform holes, providing superior structural strength, rigidity, and consistent perforation patterns for ventilation or decorative use. Both materials benefit from copper's innate corrosion resistance, thermal conductivity, and antimicrobial properties, but mesh excels in pliability while perforated sheets deliver enhanced durability.

Manufacturing Processes: Mesh vs Perforated Sheet

Copper mesh is manufactured through weaving or welding fine copper wires into a grid pattern, offering flexibility and breathability ideal for filtration and electromagnetic shielding. Copper perforated sheets are produced by punching precise round, square, or decorative holes into solid copper sheets using mechanical or CNC punching machines, providing durability and structural integrity for architectural and industrial applications. Both processes influence the material's mechanical properties, with mesh emphasizing flexibility and perforated sheets delivering strength and rigidity.

Strength and Durability Comparison

Copper mesh exhibits superior flexibility and tensile strength due to its woven structure, allowing it to withstand bending and impact without deforming. Copper perforated sheets offer enhanced durability and rigidity, providing consistent resistance against corrosion and mechanical wear in demanding environments. Both materials demonstrate excellent conductivity, but the choice depends on the application's need for structural strength versus malleability.

Flexibility and Formability Differences

Copper mesh exhibits superior flexibility due to its woven structure, allowing it to easily conform to irregular shapes and be bent without breaking. In contrast, copper perforated sheets, composed of solid metal with patterned holes, offer limited formability and are more prone to deformation or cracking when subjected to bending. This inherent difference makes copper mesh ideal for applications requiring adaptable shaping, while perforated sheets suit structural uses needing rigidity and strength.

Filtration and Screening Applications

Copper Mesh offers superior filtration efficiency due to its fine weave, providing enhanced particle retention and airflow compared to Copper Perforated Sheets, which feature larger, uniform holes ideal for screening and robust particle separation. The mesh's flexibility enables it to adapt to complex filtering systems, whereas perforated sheets excel in applications requiring structural strength and easy cleaning. Both materials utilize copper's natural antimicrobial properties, improving hygiene in filtration and screening processes across industrial and environmental applications.

Aesthetic and Design Considerations

Copper mesh offers a delicate, intricate texture ideal for decorative applications requiring transparency and light filtration, enhancing aesthetic appeal through its fine grid pattern. Copper perforated sheets provide a bolder, more industrial look with customizable hole sizes and patterns, allowing designers to create striking visual effects and structural accents. Both materials contribute unique design flexibility, with copper mesh lending itself to subtle elegance and copper perforated sheets serving as statement pieces in architectural and interior design.

Corrosion Resistance in Various Environments

Copper mesh exhibits superior corrosion resistance in highly humid and marine environments due to its flexible structure allowing better ventilation and moisture evaporation. Copper perforated sheets, while robust and structurally stronger, tend to retain moisture in their recessed areas, increasing the risk of localized corrosion in acidic or salty conditions. Both materials offer excellent durability, but copper mesh is preferred for applications requiring enhanced corrosion resistance in aggressive environments.

Cost Analysis: Mesh vs Perforated Sheet

Copper mesh generally offers a lower cost compared to copper perforated sheets due to less complex manufacturing processes and reduced material waste. The production of copper perforated sheets involves precise punching and patterning, increasing labor and machinery expenses. Budget-conscious projects often prefer copper mesh for its affordability, although the choice depends on application-specific performance requirements.

Choosing the Right Copper Material for Your Project

Copper mesh offers superior flexibility and excellent filtration capabilities, ideal for applications requiring airflow and particle screening. Copper perforated sheets provide increased structural strength and precise hole patterns, making them suitable for decorative facades, soundproofing, and protective screens. Selecting the right copper material depends on project requirements such as filtration efficiency, durability, and aesthetic preferences.

Copper Mesh vs Copper Perforated Sheet Infographic

materialdif.com

materialdif.com