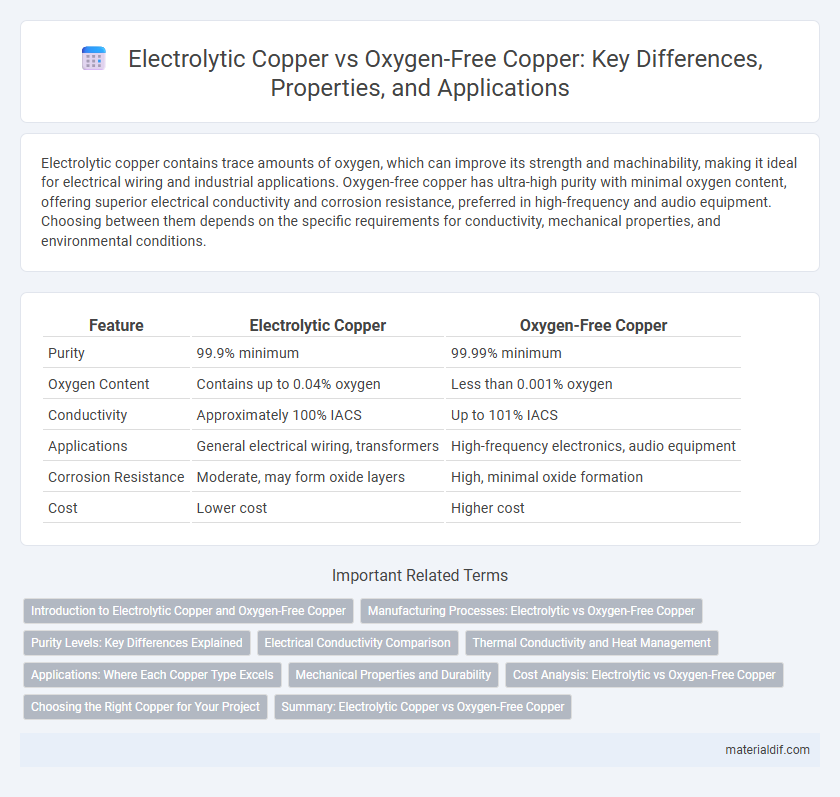

Electrolytic copper contains trace amounts of oxygen, which can improve its strength and machinability, making it ideal for electrical wiring and industrial applications. Oxygen-free copper has ultra-high purity with minimal oxygen content, offering superior electrical conductivity and corrosion resistance, preferred in high-frequency and audio equipment. Choosing between them depends on the specific requirements for conductivity, mechanical properties, and environmental conditions.

Table of Comparison

| Feature | Electrolytic Copper | Oxygen-Free Copper |

|---|---|---|

| Purity | 99.9% minimum | 99.99% minimum |

| Oxygen Content | Contains up to 0.04% oxygen | Less than 0.001% oxygen |

| Conductivity | Approximately 100% IACS | Up to 101% IACS |

| Applications | General electrical wiring, transformers | High-frequency electronics, audio equipment |

| Corrosion Resistance | Moderate, may form oxide layers | High, minimal oxide formation |

| Cost | Lower cost | Higher cost |

Introduction to Electrolytic Copper and Oxygen-Free Copper

Electrolytic copper is produced through the process of electrolytic refining, resulting in high-purity copper typically containing 99.9% copper with trace amounts of impurities, making it suitable for electrical wiring and industrial applications. Oxygen-free copper, manufactured by deoxidizing molten copper with hydrogen or vacuum melting, offers superior electrical conductivity and enhanced resistance to oxidation and hydrogen embrittlement. Both materials are essential for electronic components, but oxygen-free copper is preferred for high-frequency or sensitive electrical applications due to its minimal oxygen content.

Manufacturing Processes: Electrolytic vs Oxygen-Free Copper

Electrolytic copper is produced through an electrorefining process where impure copper anodes are dissolved and pure copper is deposited onto cathodes, ensuring high conductivity and consistent quality. Oxygen-free copper, on the other hand, undergoes a melting process in a controlled, oxygen-free atmosphere to minimize oxygen content and metallic impurities, enhancing thermal and electrical properties. The manufacturing differences result in electrolytic copper having trace oxygen levels while oxygen-free copper achieves superior conductivity and ductility due to its ultra-pure composition.

Purity Levels: Key Differences Explained

Electrolytic copper typically contains 99.9% purity with trace amounts of oxygen and other impurities, making it suitable for most electrical applications. Oxygen-Free Copper (OFC) achieves purity levels of 99.99% or higher, reducing oxygen content to less than 0.001%, which enhances electrical conductivity and minimizes oxidation risks. These purity differences critically impact performance in high-frequency transmission and sensitive electronic components requiring superior conductivity and corrosion resistance.

Electrical Conductivity Comparison

Electrolytic Copper typically contains trace amounts of oxygen, which can slightly reduce its electrical conductivity compared to Oxygen-Free Copper (OFC). Oxygen-Free Copper is refined to remove oxygen and impurities, resulting in higher purity above 99.99%, and thus superior electrical conductivity, often measured at approximately 101% IACS (International Annealed Copper Standard). This enhanced conductivity makes OFC ideal for high-performance electrical applications requiring minimal signal loss and optimal power transmission.

Thermal Conductivity and Heat Management

Electrolytic copper typically contains small amounts of oxygen, which can slightly reduce its thermal conductivity compared to oxygen-free copper, known for its purity exceeding 99.99%. Oxygen-free copper exhibits superior heat management properties due to its higher thermal conductivity, often above 390 W/m*K, making it ideal for applications requiring efficient heat dissipation. In contrast, electrolytic copper's slightly lower thermal performance remains suitable for general electrical uses but may underperform in high-precision thermal environments.

Applications: Where Each Copper Type Excels

Electrolytic copper is widely used in electrical wiring, power generation, and industrial machinery due to its high conductivity and cost-effectiveness. Oxygen-free copper excels in high-frequency and sensitive electronic applications such as audio equipment, aerospace components, and vacuum tubes because of its superior purity and enhanced thermal conductivity. Both types serve distinct roles, with electrolytic copper favored for bulk electrical infrastructure and oxygen-free copper preferred for precision electrical and thermal applications.

Mechanical Properties and Durability

Electrolytic copper, produced through electrorefining, typically contains trace oxygen levels that enhance tensile strength and hardness, making it suitable for structural applications requiring mechanical resilience. Oxygen-free copper, characterized by its high purity and minimal oxygen content, offers superior electrical conductivity and corrosion resistance, contributing to enhanced durability in high-performance electronic and vacuum environments. Mechanical properties of electrolytic copper generally favor strength, while oxygen-free copper excels in lifespan and reliability under oxidative stress.

Cost Analysis: Electrolytic vs Oxygen-Free Copper

Electrolytic copper typically costs less than oxygen-free copper due to its higher production volume and simpler refining process, making it economically favorable for large-scale industrial applications. Oxygen-free copper, with its superior purity and enhanced electrical conductivity, commands a higher price because of the additional refining steps involved to remove oxygen and impurities. Cost analysis must weigh the price differential against performance requirements, especially in high-frequency or sensitive electronic components where oxygen-free copper's properties justify the premium.

Choosing the Right Copper for Your Project

Electrolytic Copper offers high purity with minimal impurities, suitable for electrical wiring and industrial applications where cost efficiency and conductivity are crucial. Oxygen-Free Copper (OFC) provides superior electrical and thermal conductivity with enhanced corrosion resistance, ideal for high-end audio, electronics, and sensitive equipment. Choosing between Electrolytic Copper and OFC depends on project requirements for performance, durability, and budget constraints.

Summary: Electrolytic Copper vs Oxygen-Free Copper

Electrolytic copper contains trace amounts of oxygen and impurities, providing good electrical conductivity and cost-effectiveness suitable for general electrical wiring. Oxygen-free copper has extremely low oxygen content and impurities, resulting in superior conductivity, enhanced ductility, and improved corrosion resistance ideal for high-performance electronic applications. Choosing between electrolytic and oxygen-free copper depends on the required purity level, conductivity, and intended use in electrical or electronic components.

Electrolytic Copper vs Oxygen-Free Copper Infographic

materialdif.com

materialdif.com