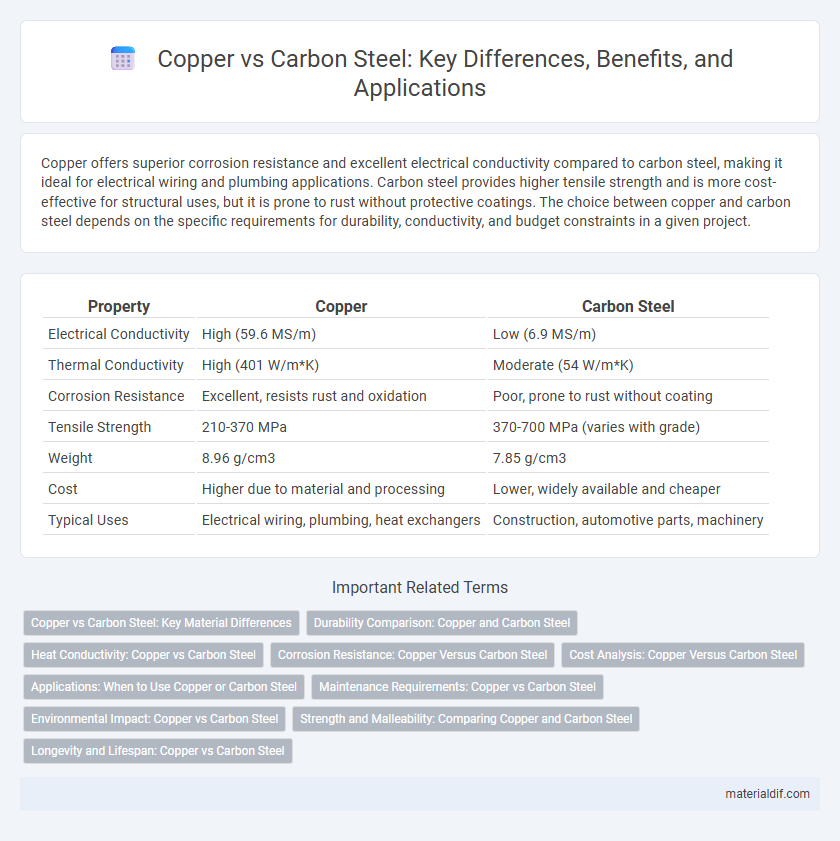

Copper offers superior corrosion resistance and excellent electrical conductivity compared to carbon steel, making it ideal for electrical wiring and plumbing applications. Carbon steel provides higher tensile strength and is more cost-effective for structural uses, but it is prone to rust without protective coatings. The choice between copper and carbon steel depends on the specific requirements for durability, conductivity, and budget constraints in a given project.

Table of Comparison

| Property | Copper | Carbon Steel |

|---|---|---|

| Electrical Conductivity | High (59.6 MS/m) | Low (6.9 MS/m) |

| Thermal Conductivity | High (401 W/m*K) | Moderate (54 W/m*K) |

| Corrosion Resistance | Excellent, resists rust and oxidation | Poor, prone to rust without coating |

| Tensile Strength | 210-370 MPa | 370-700 MPa (varies with grade) |

| Weight | 8.96 g/cm3 | 7.85 g/cm3 |

| Cost | Higher due to material and processing | Lower, widely available and cheaper |

| Typical Uses | Electrical wiring, plumbing, heat exchangers | Construction, automotive parts, machinery |

Copper vs Carbon Steel: Key Material Differences

Copper exhibits superior electrical and thermal conductivity compared to carbon steel, making it ideal for electrical wiring and heat exchangers. Carbon steel offers higher tensile strength and greater resistance to wear and impact, preferred in construction and heavy machinery. Corrosion resistance is notably better in copper, which naturally forms a protective patina, whereas carbon steel requires coatings to prevent rust.

Durability Comparison: Copper and Carbon Steel

Copper offers superior corrosion resistance compared to carbon steel, making it more durable in environments exposed to moisture and chemicals. Carbon steel is prone to rust and requires protective coatings for longevity, whereas copper naturally develops a protective patina that enhances its lifespan. The durability of copper in plumbing and electrical applications often surpasses carbon steel, reducing maintenance and replacement costs over time.

Heat Conductivity: Copper vs Carbon Steel

Copper exhibits significantly higher thermal conductivity than carbon steel, with values around 401 W/m*K compared to carbon steel's approximate 50 W/m*K. This superior heat conductivity enables copper to transfer heat more efficiently, making it ideal for applications requiring rapid heat dissipation or uniform temperature distribution. Carbon steel, with lower thermal conductivity, retains heat longer, which can be advantageous in scenarios where gradual heat transfer is desired.

Corrosion Resistance: Copper Versus Carbon Steel

Copper exhibits superior corrosion resistance compared to carbon steel due to its natural ability to form a protective oxide layer that prevents further degradation. Carbon steel, lacking this passive film, is prone to rust and requires coatings or treatments for durability in corrosive environments. Consequently, copper is often preferred in plumbing, marine, and industrial applications where long-term exposure to moisture and chemicals is common.

Cost Analysis: Copper Versus Carbon Steel

Copper generally has a higher initial cost compared to carbon steel due to its superior corrosion resistance and electrical conductivity. Carbon steel is more economical for large-scale structural applications but may incur additional maintenance expenses over time because of its susceptibility to rust. Long-term cost analysis favors copper in environments requiring durability and minimal upkeep, while carbon steel suits budget-sensitive projects with controlled exposure conditions.

Applications: When to Use Copper or Carbon Steel

Copper excels in applications requiring excellent electrical conductivity, corrosion resistance, and thermal performance, such as electrical wiring, plumbing, and HVAC systems. Carbon steel is preferred in structural, automotive, and heavy machinery industries due to its high strength, durability, and cost-effectiveness for load-bearing components. Choosing copper or carbon steel depends on the need for corrosion resistance and conductivity versus mechanical strength and budget constraints.

Maintenance Requirements: Copper vs Carbon Steel

Copper requires minimal maintenance due to its natural corrosion resistance and antimicrobial properties, reducing the need for frequent cleaning or protective treatments. Carbon steel demands regular maintenance, including rust prevention measures such as coating or painting, and periodic inspections to avoid corrosion-related damage. The long-term upkeep costs of carbon steel typically exceed those of copper, making copper more favorable for applications where low maintenance is crucial.

Environmental Impact: Copper vs Carbon Steel

Copper demonstrates a lower environmental impact compared to carbon steel due to its high recyclability rate of over 90%, which significantly reduces the need for virgin material extraction and energy consumption. Carbon steel production emits higher levels of CO2, contributing more substantially to greenhouse gas emissions and environmental degradation. The durability and corrosion resistance of copper also extend product lifespan, minimizing waste and resource use over time.

Strength and Malleability: Comparing Copper and Carbon Steel

Copper exhibits superior malleability, allowing it to be easily shaped and formed without breaking, which is ideal for intricate applications. Carbon steel offers significantly higher tensile strength, making it more suitable for structural and load-bearing uses. The balance between copper's flexibility and carbon steel's strength determines their respective industrial applications in construction, plumbing, and manufacturing.

Longevity and Lifespan: Copper vs Carbon Steel

Copper offers superior longevity compared to carbon steel due to its natural corrosion resistance and ability to withstand harsh environmental conditions without rusting. Carbon steel, while durable, is prone to oxidation and requires protective coatings to prevent degradation, limiting its lifespan. Typical copper components can last over 50 years in plumbing and electrical applications, whereas untreated carbon steel may only last 15-20 years before significant maintenance or replacement is needed.

Copper vs Carbon Steel Infographic

materialdif.com

materialdif.com