Beryllium copper offers exceptional strength and hardness combined with excellent electrical conductivity, making it ideal for applications requiring durability and high performance. Oxygen-free copper, known for its high purity and superior electrical and thermal conductivity, is preferred in sensitive electronic components and high-frequency equipment. Choosing between beryllium copper and oxygen-free copper depends on the specific demand for mechanical strength versus electrical purity in the intended application.

Table of Comparison

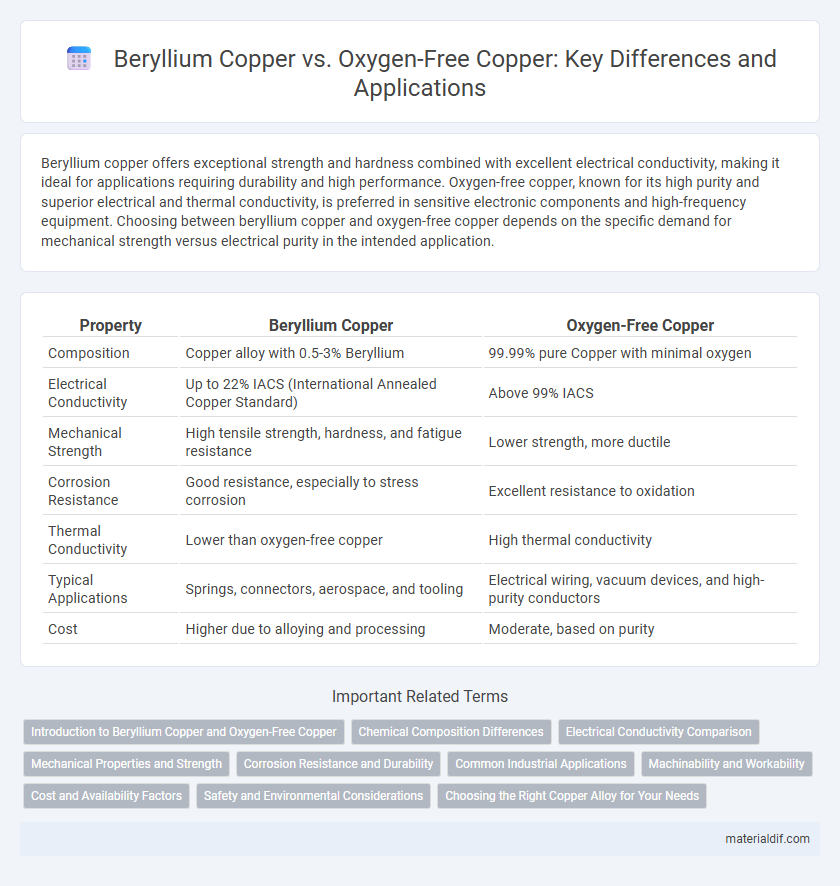

| Property | Beryllium Copper | Oxygen-Free Copper |

|---|---|---|

| Composition | Copper alloy with 0.5-3% Beryllium | 99.99% pure Copper with minimal oxygen |

| Electrical Conductivity | Up to 22% IACS (International Annealed Copper Standard) | Above 99% IACS |

| Mechanical Strength | High tensile strength, hardness, and fatigue resistance | Lower strength, more ductile |

| Corrosion Resistance | Good resistance, especially to stress corrosion | Excellent resistance to oxidation |

| Thermal Conductivity | Lower than oxygen-free copper | High thermal conductivity |

| Typical Applications | Springs, connectors, aerospace, and tooling | Electrical wiring, vacuum devices, and high-purity conductors |

| Cost | Higher due to alloying and processing | Moderate, based on purity |

Introduction to Beryllium Copper and Oxygen-Free Copper

Beryllium Copper is a high-strength copper alloy known for its exceptional hardness, conductivity, and corrosion resistance, making it ideal for aerospace and electronic applications. Oxygen-Free Copper is a highly pure copper variant with minimal oxygen content, offering superior electrical and thermal conductivity used primarily in critical electrical components and audio equipment. Both materials serve specialized roles where performance and reliability are paramount, with beryllium copper emphasizing mechanical strength and oxygen-free copper optimizing purity and conductivity.

Chemical Composition Differences

Beryllium Copper contains approximately 0.5-3% beryllium along with copper, enhancing its strength and hardness through the addition of this alloying element. Oxygen-Free Copper is characterized by a high purity level with minimal oxygen content, typically less than 0.001%, to improve electrical conductivity and prevent oxidation. The key chemical composition difference lies in Beryllium Copper's alloyed nature versus the near-pure elemental state of Oxygen-Free Copper.

Electrical Conductivity Comparison

Beryllium copper offers moderate electrical conductivity, typically around 20-25% IACS (International Annealed Copper Standard), making it suitable for applications requiring strength and durability alongside conductivity. Oxygen-free copper (OFC), with a conductivity of about 101% IACS, provides superior electrical performance due to its high purity and low oxygen content. Choosing between beryllium copper and oxygen-free copper depends on the balance of conductivity needs and mechanical properties required in specific electrical applications.

Mechanical Properties and Strength

Beryllium Copper exhibits superior mechanical properties with tensile strength ranging from 1,200 to 1,400 MPa, making it highly resistant to wear and fatigue, while oxygen-free copper generally has a tensile strength of around 210 to 250 MPa. The alloying of beryllium enhances hardness and elasticity, enabling Beryllium Copper to maintain excellent strength at elevated temperatures, unlike oxygen-free copper, which is softer and more ductile but lacks comparable mechanical robustness. This makes Beryllium Copper ideal for high-stress applications requiring durability and resilience, whereas oxygen-free copper excels in conductivity but has limited mechanical strength.

Corrosion Resistance and Durability

Beryllium copper exhibits superior corrosion resistance and durability due to its alloy composition, which enhances strength and resistance to environmental degradation compared to oxygen-free copper. Oxygen-free copper, known for its high electrical conductivity, is more prone to oxidation and corrosion over time, especially in harsh or marine environments. The enhanced mechanical properties of beryllium copper make it ideal for applications requiring long-term durability and resistance to wear and corrosion.

Common Industrial Applications

Beryllium copper is widely used in industrial applications requiring high strength, excellent conductivity, and resistance to fatigue and corrosion, such as aerospace components, precision instruments, and electrical connectors. Oxygen-free copper, known for superior electrical and thermal conductivity, finds common application in high-performance electronic wiring, vacuum tubes, and audio equipment where low oxygen content enhances signal transmission and durability. Both materials serve critical roles in manufacturing sectors depending on specific mechanical properties and conductivity needs.

Machinability and Workability

Beryllium copper offers superior machinability due to its high strength and hardness, making it ideal for precision components requiring tight tolerances, whereas oxygen-free copper excels in electrical conductivity but is softer and less suitable for complex machining. The exceptional workability of oxygen-free copper allows it to be easily formed and shaped with minimal risk of cracking, beneficial for applications demanding excellent ductility. Beryllium copper combines strength and moderate workability, providing a balanced solution for parts needing both durability and manufacturability.

Cost and Availability Factors

Beryllium copper commands a higher price due to its specialized alloy composition and limited production volume compared to oxygen-free copper, which is more readily available and cost-effective for general electrical and thermal applications. The scarcity of beryllium in supply chains increases its market cost, while oxygen-free copper benefits from widespread manufacturing processes and abundant raw material sources. Cost-conscious industries often opt for oxygen-free copper for bulk use, reserving beryllium copper for niche applications requiring superior mechanical strength and corrosion resistance.

Safety and Environmental Considerations

Beryllium copper contains trace amounts of beryllium, which can pose significant health risks such as chronic beryllium disease if proper handling and protective measures are not followed during manufacturing and machining processes. Oxygen-free copper, being purer and free from harmful impurities and additives, offers a safer alternative with minimal environmental impact during recycling and use. Both materials require responsible management, but oxygen-free copper's environmental footprint is typically lower due to its reduced toxicity and improved recyclability.

Choosing the Right Copper Alloy for Your Needs

Beryllium copper offers exceptional strength and hardness combined with excellent electrical conductivity, making it ideal for applications requiring durability and wear resistance such as aerospace components and precision instruments. Oxygen-free copper, characterized by its high purity and superior electrical and thermal conductivity, is preferred for high-fidelity audio equipment and sensitive electronic devices where minimizing signal loss is critical. Selecting between beryllium copper and oxygen-free copper depends on balancing mechanical strength versus conductivity requirements to match specific industrial or electronic performance needs.

Beryllium Copper vs Oxygen-Free Copper Infographic

materialdif.com

materialdif.com