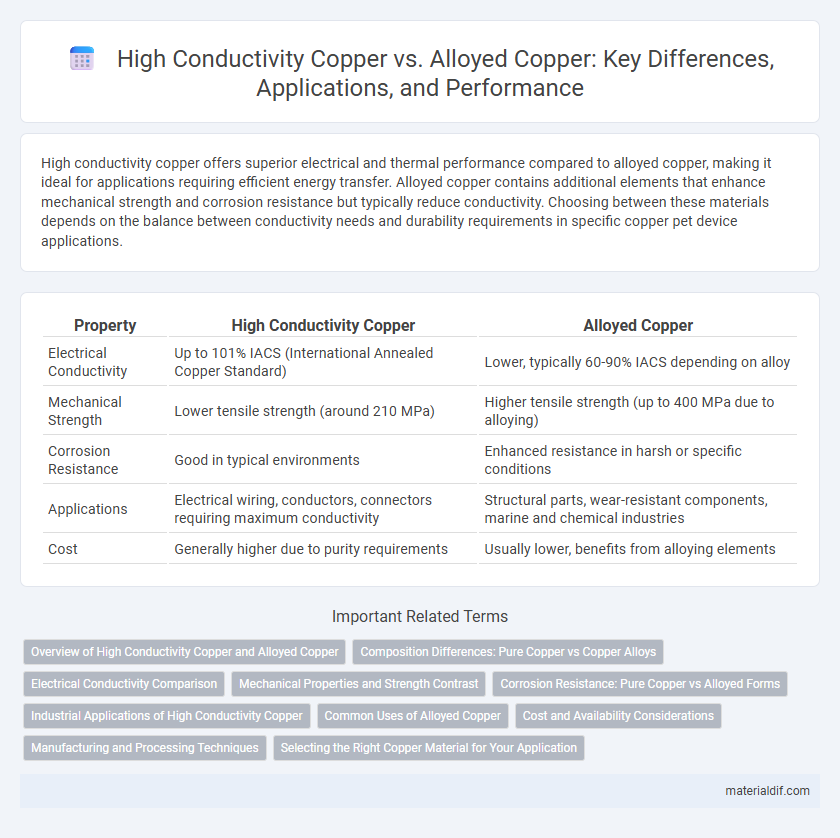

High conductivity copper offers superior electrical and thermal performance compared to alloyed copper, making it ideal for applications requiring efficient energy transfer. Alloyed copper contains additional elements that enhance mechanical strength and corrosion resistance but typically reduce conductivity. Choosing between these materials depends on the balance between conductivity needs and durability requirements in specific copper pet device applications.

Table of Comparison

| Property | High Conductivity Copper | Alloyed Copper |

|---|---|---|

| Electrical Conductivity | Up to 101% IACS (International Annealed Copper Standard) | Lower, typically 60-90% IACS depending on alloy |

| Mechanical Strength | Lower tensile strength (around 210 MPa) | Higher tensile strength (up to 400 MPa due to alloying) |

| Corrosion Resistance | Good in typical environments | Enhanced resistance in harsh or specific conditions |

| Applications | Electrical wiring, conductors, connectors requiring maximum conductivity | Structural parts, wear-resistant components, marine and chemical industries |

| Cost | Generally higher due to purity requirements | Usually lower, benefits from alloying elements |

Overview of High Conductivity Copper and Alloyed Copper

High conductivity copper is primarily composed of pure copper with minimal impurities, delivering excellent electrical and thermal conductivity ideal for electrical wiring and electronic components. Alloyed copper contains additional elements such as zinc, tin, or nickel, which enhance mechanical strength and corrosion resistance but reduce conductivity compared to pure copper. The choice between high conductivity copper and alloyed copper depends on the specific application requirements, balancing conductivity with durability and environmental resilience.

Composition Differences: Pure Copper vs Copper Alloys

High conductivity copper primarily consists of nearly 99.9% pure copper, ensuring minimal impurities that allow for maximum electrical and thermal conductivity. In contrast, alloyed copper incorporates elements such as zinc, tin, or nickel to enhance mechanical strength, corrosion resistance, and durability, but these additions reduce overall conductivity. The compositional trade-off between pure copper and copper alloys directly impacts their suitability for electrical wiring versus structural applications.

Electrical Conductivity Comparison

High conductivity copper, typically with a purity of 99.9% or higher, exhibits exceptional electrical conductivity, often around 58 MS/m, making it ideal for applications requiring minimal resistance and maximal current flow. Alloyed copper, containing elements such as silver, nickel, or tin, generally shows reduced conductivity, often ranging between 40 to 55 MS/m, due to increased electron scattering caused by impurities. This conductivity difference directly impacts efficiency in electrical systems, with high conductivity copper preferred for power transmission and sensitive electronic components.

Mechanical Properties and Strength Contrast

High conductivity copper exhibits superior electrical performance but lower mechanical strength and hardness compared to alloyed copper, which incorporates elements such as silver, nickel, or chromium to enhance tensile strength and wear resistance. Alloyed copper achieves improved mechanical properties through solid solution strengthening and precipitation hardening, making it suitable for demanding structural applications where durability is critical. The trade-off between electrical conductivity and mechanical strength is pivotal in selecting the appropriate copper type for specific engineering uses.

Corrosion Resistance: Pure Copper vs Alloyed Forms

Pure high conductivity copper exhibits superior corrosion resistance due to its homogeneous atomic structure, minimizing sites for corrosive attack and promoting the formation of a stable oxide layer. Alloyed copper, while offering enhanced mechanical strength, often introduces elements like nickel or tin that can create galvanic cells and increase susceptibility to localized corrosion. Selecting between pure and alloyed copper depends on balancing electrical performance and environmental durability requirements in specific applications.

Industrial Applications of High Conductivity Copper

High conductivity copper, characterized by its minimal electrical resistance and high purity, is extensively used in industrial applications such as electrical wiring, transformers, and electromagnets where efficient current flow is critical. In contrast to alloyed copper, which contains added elements to enhance durability or corrosion resistance but reduces conductivity, high conductivity copper ensures optimal performance in power transmission and sensitive electronic components. Industries relying on rapid and reliable electrical transmission prioritize high conductivity copper for its superior conductivity values typically exceeding 101% IACS (International Annealed Copper Standard).

Common Uses of Alloyed Copper

Alloyed copper, often combined with elements like tin, zinc, or nickel, is widely used in applications requiring enhanced strength and corrosion resistance, such as plumbing fittings, marine hardware, and electrical connectors. Its improved mechanical properties make it suitable for industrial machinery components and architectural elements exposed to harsh environments. Unlike high conductivity copper, which prioritizes electrical performance, alloyed copper balances conductivity with durability for practical, long-lasting use.

Cost and Availability Considerations

High conductivity copper, known for its superior electrical performance, typically commands a higher price due to its purity and demand in critical applications like electrical wiring and electronics. Alloyed copper, while offering enhanced mechanical strength and corrosion resistance, tends to be more cost-effective and widely available, making it suitable for structural and industrial uses. Cost considerations often favor alloyed copper in large-scale manufacturing, whereas availability of high conductivity copper can be limited by market fluctuations and refining capacities.

Manufacturing and Processing Techniques

High conductivity copper, primarily made of nearly pure copper, undergoes processes like electrorefining and annealing to maximize electrical conductivity, making it ideal for applications demanding low electrical resistance such as power transmission and electronics. Alloyed copper contains elements like zinc, tin, or nickel, which improve mechanical properties and corrosion resistance through casting, forging, or powder metallurgy techniques, but reduce conductivity compared to pure copper. Manufacturing high conductivity copper prioritizes minimizing impurities and precise thermal treatments, whereas alloyed copper emphasizes controlled alloying and complex shaping to balance strength and conductivity.

Selecting the Right Copper Material for Your Application

High conductivity copper offers superior electrical and thermal performance, making it ideal for applications requiring efficient energy transfer such as electrical wiring and heat exchangers. Alloyed copper, containing elements like nickel or tin, provides enhanced strength, corrosion resistance, and wear properties, suitable for mechanical parts and harsh environments. Selecting the right copper material depends on balancing conductivity needs with mechanical durability and environmental conditions of the intended application.

High Conductivity Copper vs Alloyed Copper Infographic

materialdif.com

materialdif.com