Electrolytic copper offers superior purity, typically around 99.99%, achieved through an electrochemical refining process that removes impurities more effectively than fire-refined copper. Fire-refined copper undergoes melting and oxidation to eliminate most contaminants but generally contains higher levels of impurities, making it less suitable for high conductivity applications. The choice between electrolytic and fire-refined copper depends on the required electrical conductivity and purity standards in industrial uses.

Table of Comparison

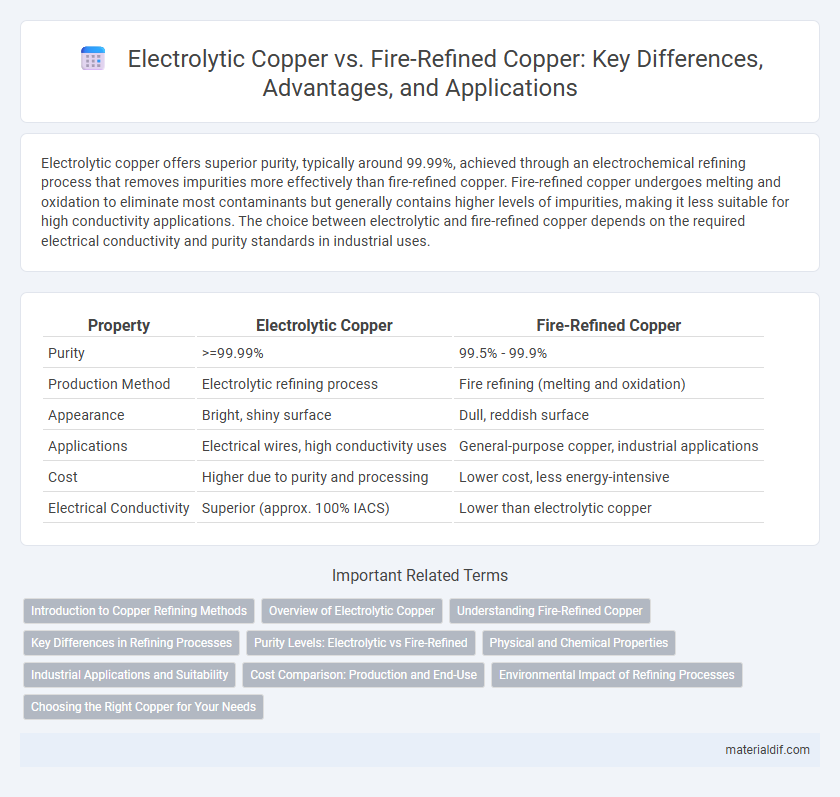

| Property | Electrolytic Copper | Fire-Refined Copper |

|---|---|---|

| Purity | >=99.99% | 99.5% - 99.9% |

| Production Method | Electrolytic refining process | Fire refining (melting and oxidation) |

| Appearance | Bright, shiny surface | Dull, reddish surface |

| Applications | Electrical wires, high conductivity uses | General-purpose copper, industrial applications |

| Cost | Higher due to purity and processing | Lower cost, less energy-intensive |

| Electrical Conductivity | Superior (approx. 100% IACS) | Lower than electrolytic copper |

Introduction to Copper Refining Methods

Electrolytic copper undergoes purification through an electrochemical process that produces extremely high purity levels, typically exceeding 99.99%, making it ideal for electrical applications. Fire-refined copper is produced by melting and oxidizing blister copper to remove impurities, yielding a purity of around 99.5% to 99.9%, commonly used in applications where ultra-high purity is less critical. Both refining methods transform raw copper into usable forms but differ significantly in purity, cost, and specific industrial applications.

Overview of Electrolytic Copper

Electrolytic copper is produced through an electrolytic refining process that ensures a purity level exceeding 99.99%, making it ideal for electrical applications requiring superior conductivity. This process involves dissolving impure copper anodes in an acidic solution and depositing pure copper onto cathodes, resulting in a highly uniform and contaminant-free metal. Compared to fire-refined copper, electrolytic copper exhibits enhanced mechanical properties and superior corrosion resistance, which are critical in high-performance electrical wiring and electronic components.

Understanding Fire-Refined Copper

Fire-refined copper is produced by melting blister copper and removing impurities through oxidation, resulting in improved purity compared to raw copper but lower than electrolytic copper. This process enhances the copper's conductivity and mechanical properties, making it suitable for less demanding electrical applications. Unlike electrolytic copper, which achieves purity above 99.99% through electrolysis, fire-refined copper typically attains purity around 99.5%, balancing cost-efficiency with functional quality.

Key Differences in Refining Processes

Electrolytic copper is produced through an electrolytic refining process that uses an electric current to dissolve impure copper anodes and deposit pure copper onto cathodes, resulting in extremely high purity levels of 99.99%. Fire-refined copper undergoes a pyrometallurgical process involving melting, oxidation, and reduction steps to remove impurities, achieving purity of around 99.5% to 99.9%. The primary difference lies in the electrolytic method's ability to achieve superior purity with fewer contaminants compared to the thermal treatment used in fire refining.

Purity Levels: Electrolytic vs Fire-Refined

Electrolytic copper boasts higher purity levels, often exceeding 99.99%, due to its refining process involving electrolysis that removes impurities effectively. Fire-refined copper typically achieves purity around 99.5% to 99.9%, as it undergoes melting and oxidation to eliminate impurities but does not reach the extreme refinement of the electrolytic method. The purity level directly impacts conductivity and suitability for high-performance electrical applications, making electrolytic copper the preferred choice for electronic components and wiring.

Physical and Chemical Properties

Electrolytic copper exhibits higher purity levels, typically 99.99%, resulting in superior electrical conductivity and minimal impurities compared to fire-refined copper, which generally contains about 99.9% purity. Fire-refined copper retains slightly higher levels of oxygen, sulfur, and other trace elements, impacting its ductility and making it less suitable for high-precision electrical applications. Physically, electrolytic copper has a more uniform crystal structure and fewer inclusions, enhancing its mechanical strength and corrosion resistance relative to fire-refined copper.

Industrial Applications and Suitability

Electrolytic copper, known for its high purity exceeding 99.99%, is ideal for electrical applications such as wiring and circuit boards due to its superior conductivity and corrosion resistance. Fire-refined copper, with slightly lower purity around 99.5%, suits applications requiring moderate electrical performance but greater mechanical strength, including plumbing and roofing materials. Industrial suitability depends on the balance between electrical conductivity, mechanical properties, and cost-efficiency, with electrolytic copper favored in electronics and fire-refined copper preferred in construction.

Cost Comparison: Production and End-Use

Electrolytic copper generally incurs higher production costs due to the energy-intensive electrolysis process, making it more expensive than fire-refined copper, which relies on traditional smelting and refining. The superior purity and conductivity of electrolytic copper justify its higher price in high-performance electrical applications, whereas fire-refined copper is favored in less sensitive uses where cost efficiency is critical. End-use industries select based on performance requirements and budget constraints, balancing the cost differences against the copper's conductivity and purity.

Environmental Impact of Refining Processes

Electrolytic copper refining produces higher purity copper with significantly lower energy consumption and reduced greenhouse gas emissions compared to fire-refined copper, which relies on combustion processes that release sulfur dioxide and other pollutants. The electrolytic process uses electric currents to deposit pure copper onto cathodes, minimizing waste and harmful byproducts, whereas fire refining involves multiple smelting steps that increase environmental degradation. As a result, electrolytic copper is considered more environmentally sustainable, contributing to cleaner production and lower ecological footprints in the copper industry.

Choosing the Right Copper for Your Needs

Electrolytic copper offers high purity levels of up to 99.99%, making it ideal for electrical wiring and electronic components where conductivity is crucial. Fire-refined copper, with purity around 99.5%, is better suited for applications requiring good corrosion resistance and mechanical strength, such as plumbing and architectural uses. Selecting the right copper depends on the specific conductivity, strength, and corrosion resistance requirements of your project.

Electrolytic Copper vs Fire-Refined Copper Infographic

materialdif.com

materialdif.com