Copper strip features a flat, narrow profile ideal for electrical grounding, welding, and manufacturing applications where precise dimensions are required. Copper ribbon, in contrast, is typically thicker and more flexible, making it suitable for heavy-duty electrical connections, busbars, and industrial grounding systems. Both materials provide excellent conductivity and corrosion resistance but are chosen based on specific mechanical and electrical requirements.

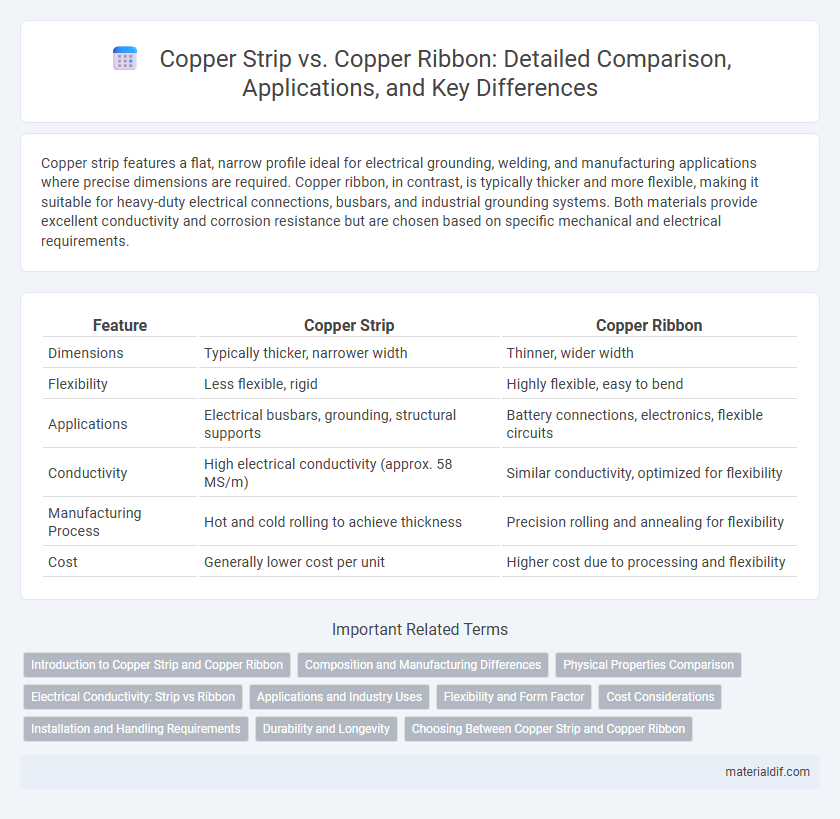

Table of Comparison

| Feature | Copper Strip | Copper Ribbon |

|---|---|---|

| Dimensions | Typically thicker, narrower width | Thinner, wider width |

| Flexibility | Less flexible, rigid | Highly flexible, easy to bend |

| Applications | Electrical busbars, grounding, structural supports | Battery connections, electronics, flexible circuits |

| Conductivity | High electrical conductivity (approx. 58 MS/m) | Similar conductivity, optimized for flexibility |

| Manufacturing Process | Hot and cold rolling to achieve thickness | Precision rolling and annealing for flexibility |

| Cost | Generally lower cost per unit | Higher cost due to processing and flexibility |

Introduction to Copper Strip and Copper Ribbon

Copper strip and copper ribbon are versatile forms of copper used extensively in electrical, construction, and manufacturing industries due to their excellent conductivity and corrosion resistance. Copper strips are typically flat, thin pieces with uniform thickness, ideal for grounding, bus bars, and electronic components, while copper ribbons are narrower and more flexible, suited for applications requiring easy bending and compact installations. Both materials offer high electrical conductivity and durability, making them essential in renewable energy systems, telecommunications, and automotive sectors.

Composition and Manufacturing Differences

Copper strips are typically composed of electrolytic tough pitch (ETP) copper with high purity levels around 99.9%, produced through hot rolling and subsequent cold rolling processes to achieve uniform thickness and enhanced mechanical properties. Copper ribbons also utilize high-purity copper but are often processed using precision rolling or casting techniques to create thinner, narrower profiles with tighter dimensional tolerances. Manufacturing differences influence conductivity and flexibility, where strips are bulkier and ideal for industrial applications, while ribbons serve specialized electrical and thermal interfacing roles due to their fine dimensions and controlled composition.

Physical Properties Comparison

Copper strips typically have a standardized thickness and width, offering uniform electrical conductivity and excellent tensile strength suitable for industrial applications. Copper ribbons are thinner, more flexible, and can be easily bent or formed, making them ideal for intricate electronic components requiring precise shaping. Both materials exhibit high thermal conductivity and corrosion resistance, but strips generally provide greater mechanical durability compared to ribbons.

Electrical Conductivity: Strip vs Ribbon

Copper strips and copper ribbons both offer excellent electrical conductivity, but copper strips typically provide a lower resistance path due to their greater thickness, enhancing current-carrying capacity in heavy-duty applications. Copper ribbons, being thinner and more flexible, suit precision electronics and delicate circuitry where efficient conductivity must align with space constraints. Optimizing electrical performance depends on matching the conductivity, cross-sectional area, and mechanical flexibility of copper strip or ribbon to specific circuit requirements.

Applications and Industry Uses

Copper strips are widely used in electrical applications such as busbars, grounding, and connectors due to their excellent conductivity and ease of fabrication, making them essential in power distribution and transformer manufacturing. Copper ribbons, characterized by their narrower width and flexibility, are preferred in applications like winding coils for electric motors, transformers, and inductors, where precise dimensions and efficient space utilization are critical. Both Copper strips and ribbons serve vital roles in industries including electronics, automotive, aerospace, and renewable energy for their superior electrical, thermal, and mechanical properties.

Flexibility and Form Factor

Copper strip offers greater rigidity and is typically used in applications requiring structural support, while copper ribbon provides superior flexibility ideal for bending and wrapping in confined spaces. The thinner, narrower form factor of copper ribbon enhances its adaptability in intricate electrical and grounding systems where space constraints are critical. Copper ribbon's pliability reduces stress during installation, making it the preferred choice for dynamic or flexible connections compared to the stiffer copper strip.

Cost Considerations

Copper strip offers a cost-effective solution for applications requiring high conductivity and thickness, often priced lower per unit weight compared to copper ribbon due to simpler manufacturing processes. Copper ribbon, while typically more expensive, provides enhanced flexibility and precision in thin, narrow widths, justifying its higher cost for specialized electrical and electronics uses. Evaluating project requirements, including mechanical properties and dimensional tolerances, is essential to balance cost-efficiency between copper strip and copper ribbon.

Installation and Handling Requirements

Copper strip offers greater rigidity and is easier to handle during installation, making it suitable for applications requiring precise alignment and structural support. Copper ribbon is more flexible and lightweight, which simplifies bending and shaping but may require careful handling to prevent kinks or damage. Installation of copper ribbon often demands additional securing techniques compared to copper strip to maintain stability in electrical or grounding systems.

Durability and Longevity

Copper strips exhibit superior durability compared to copper ribbons due to their thicker gauge and rigid structure, which resist deformation and wear over time. The longevity of copper strips is enhanced by their resistance to corrosion and mechanical stress, making them ideal for heavy-duty electrical and industrial applications. Copper ribbons, thinner and more flexible, offer less durability but are suitable for applications requiring bending and intricate shapes.

Choosing Between Copper Strip and Copper Ribbon

Choosing between copper strip and copper ribbon depends on specific application requirements such as flexibility, conductivity, and mechanical strength. Copper strips typically offer greater rigidity and are preferred for structural or grounding purposes, while copper ribbons provide enhanced flexibility for winding coils and making electrical connections in confined spaces. Material thickness, width, and surface finish also influence selection to ensure optimal performance in electrical and industrial uses.

Copper Strip vs Copper Ribbon Infographic

materialdif.com

materialdif.com