C101 copper and C110 copper are both high-purity electrolytic tough pitch (ETP) coppers commonly used in electrical applications. C110 copper contains at least 99.9% purity, offering excellent electrical conductivity, while C101 copper has a purity of approximately 99.99%, resulting in superior conductivity and better performance in highly demanding electrical environments. Both types are suitable for electrical wiring, but C101 copper is preferred for applications requiring maximum conductivity and corrosion resistance.

Table of Comparison

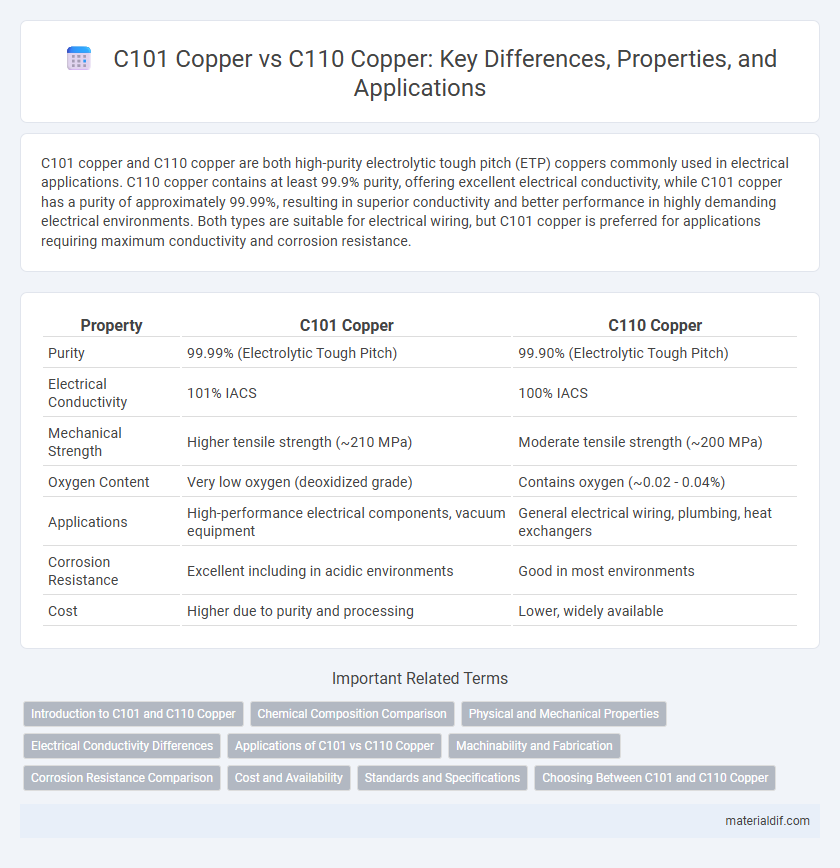

| Property | C101 Copper | C110 Copper |

|---|---|---|

| Purity | 99.99% (Electrolytic Tough Pitch) | 99.90% (Electrolytic Tough Pitch) |

| Electrical Conductivity | 101% IACS | 100% IACS |

| Mechanical Strength | Higher tensile strength (~210 MPa) | Moderate tensile strength (~200 MPa) |

| Oxygen Content | Very low oxygen (deoxidized grade) | Contains oxygen (~0.02 - 0.04%) |

| Applications | High-performance electrical components, vacuum equipment | General electrical wiring, plumbing, heat exchangers |

| Corrosion Resistance | Excellent including in acidic environments | Good in most environments |

| Cost | Higher due to purity and processing | Lower, widely available |

Introduction to C101 and C110 Copper

C101 copper, also known as electrolytic tough pitch (ETP) copper, features high electrical conductivity and is commonly used in electrical applications due to its purity of about 99.9%. C110 copper, often referred to as commercially pure copper, offers superior ductility and corrosion resistance, making it ideal for architectural and industrial uses. Both grades maintain excellent thermal conductivity but differ in mechanical properties and specific applications.

Chemical Composition Comparison

C101 copper, also known as oxygen-free electronic (OFE) copper, contains a minimum copper purity of 99.99% with oxygen content less than 0.0005%, enhancing its electrical conductivity and corrosion resistance. C110 copper, or electrolytic tough pitch (ETP) copper, has a copper purity of approximately 99.9% and includes oxygen around 0.02-0.04%, which improves workability but slightly reduces electrical conductivity compared to C101. The lower oxygen content in C101 copper makes it preferred for high-performance electronic and electrical applications requiring superior conductivity and minimal impurities.

Physical and Mechanical Properties

C101 copper exhibits higher electrical conductivity, typically around 101% IACS (International Annealed Copper Standard), compared to C110 copper, which has approximately 100% IACS. Physically, C101 is often used in applications requiring superior thermal and electrical performance due to its higher purity (99.99% copper), while C110 contains slightly less purity (99.9%) but offers greater mechanical strength and improved machinability. Mechanically, C110 copper has a tensile strength ranging from 210 to 300 MPa, which surpasses C101's lower tensile strength, making C110 better suited for structural components subject to mechanical stress.

Electrical Conductivity Differences

C101 copper offers higher electrical conductivity, approximately 101% IACS (International Annealed Copper Standard), compared to C110 copper's 100% IACS. This slight conductivity advantage makes C101 copper ideal for high-performance electrical applications requiring minimal resistance. Both grades possess excellent thermal conductivity and corrosion resistance, but C101's superior purity enhances its efficiency in electrical wiring and components.

Applications of C101 vs C110 Copper

C101 copper, renowned for its high purity (99.99%), is commonly used in applications requiring excellent electrical conductivity such as electrical wiring, transformers, and electrical connectors. C110 copper, slightly less pure but more cost-effective, finds extensive use in plumbing, roofing, and decorative applications where corrosion resistance and workability are critical. Both C101 and C110 copper grades serve vital roles in industrial and construction sectors, but C101 is preferred for precision electrical uses while C110 is favored for general-purpose and architectural components.

Machinability and Fabrication

C101 copper offers superior electrical conductivity but lower machinability compared to C110 copper, which is specifically engineered for enhanced machinability in applications requiring extensive fabrication. C110 copper contains a small amount of phosphorus, improving chip formation and reducing tool wear during machining processes. This makes C110 ideal for complex turning, milling, and drilling operations, while C101 is preferred for components emphasizing conductivity over manufacturability.

Corrosion Resistance Comparison

C101 copper exhibits superior corrosion resistance compared to C110 copper due to its higher purity level, which reduces the presence of impurities that can accelerate corrosion. C110 copper, while still offering good corrosion resistance, contains slightly more impurities that can make it more susceptible to oxidation and corrosion in certain environments. The enhanced corrosion resistance of C101 makes it ideal for applications in chemical and electrical industries where durability and longevity are critical.

Cost and Availability

C101 copper offers higher purity and superior electrical conductivity but comes at a higher cost compared to C110 copper, which is less expensive due to its slightly lower purity and more common usage. C110 copper is widely available and preferred for general electrical applications, while C101 is often reserved for specialized, high-performance requirements where cost is less critical. Availability of C101 is more limited due to its stringent manufacturing processes, making C110 the more accessible choice in the market.

Standards and Specifications

C101 copper meets ASTM B170 and B161 standards, ensuring high purity with a minimum of 99.99% copper, primarily used in electrical applications requiring excellent conductivity. C110 copper, also known as electro-refined copper, conforms to ASTM B170 and B152 specifications, with a slightly lower purity of 99.9%, making it suitable for general electrical and industrial purposes. Both C101 and C110 grades comply with UNS C10100 and C11000 classifications, supporting consistent quality and performance across various copper products.

Choosing Between C101 and C110 Copper

C101 copper offers superior oxygen-free purity with a minimum of 99.99% copper content, making it ideal for high-end electrical and electronic applications requiring excellent conductivity and corrosion resistance. C110 copper, while slightly lower in purity at 99.90% minimum, provides excellent electrical and thermal conductivity and is more cost-effective for general-purpose electrical wiring and industrial uses. Selecting between C101 and C110 copper depends on the balance between performance requirements and budget constraints, with C101 favored for specialty, high-performance needs and C110 suited for conventional applications.

C101 Copper vs C110 Copper Infographic

materialdif.com

materialdif.com