DHP copper, or Deoxidized High Phosphorus copper, contains a small amount of phosphorus that enhances its corrosion resistance and strength, making it ideal for plumbing and marine applications. ETP copper, or Electrolytic Tough Pitch copper, offers high electrical conductivity and is commonly used in electrical wiring and electronics due to its purity and ductility. Choosing between DHP and ETP copper depends on the need for mechanical strength and corrosion resistance versus excellent electrical conductivity.

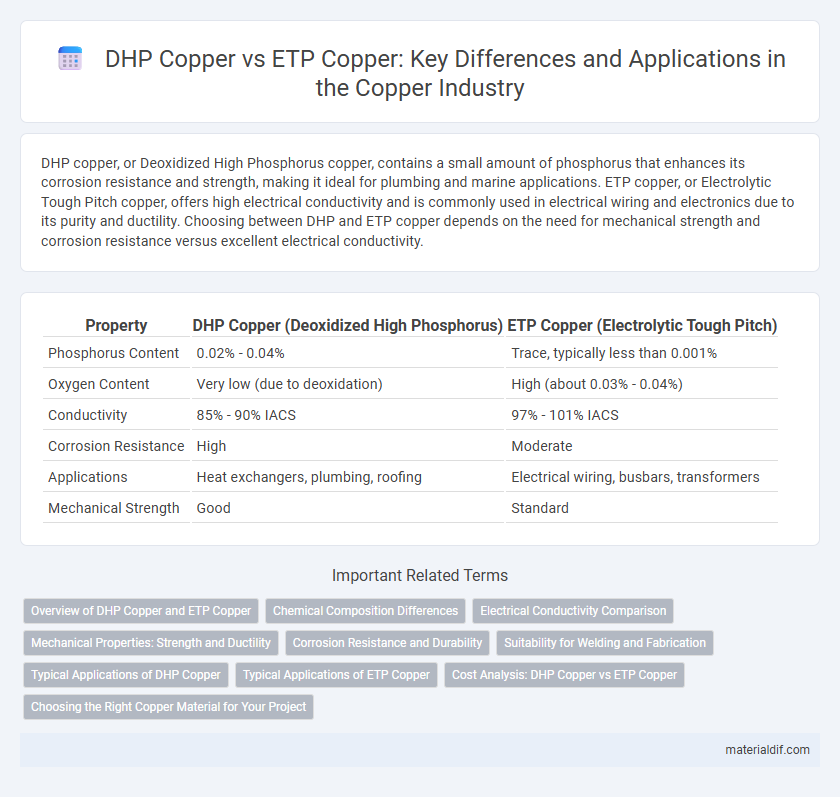

Table of Comparison

| Property | DHP Copper (Deoxidized High Phosphorus) | ETP Copper (Electrolytic Tough Pitch) |

|---|---|---|

| Phosphorus Content | 0.02% - 0.04% | Trace, typically less than 0.001% |

| Oxygen Content | Very low (due to deoxidation) | High (about 0.03% - 0.04%) |

| Conductivity | 85% - 90% IACS | 97% - 101% IACS |

| Corrosion Resistance | High | Moderate |

| Applications | Heat exchangers, plumbing, roofing | Electrical wiring, busbars, transformers |

| Mechanical Strength | Good | Standard |

Overview of DHP Copper and ETP Copper

DHP copper (Deoxidized High Phosphorus) contains a precise amount of phosphorus, enhancing its resistance to hydrogen embrittlement and improving strength and hardness, making it ideal for brazing applications. ETP copper (Electrolytic Tough Pitch) features high conductivity with a minimum of 99.9% copper content and a slight oxygen presence, commonly used in electrical wiring and conductive components. Both grades serve critical roles in industrial applications, with DHP favored for mechanical strength and ETP optimized for electrical performance.

Chemical Composition Differences

DHP copper, or Deoxidized High Phosphorus copper, contains a higher phosphorus content typically around 0.02-0.04%, which improves its resistance to hydrogen embrittlement and enhances strength, making it ideal for plumbing and industrial applications. ETP copper, or Electrolytic Tough Pitch copper, has a purity level of about 99.9% copper with trace oxygen content around 0.02-0.04%, offering excellent electrical conductivity but lower resistance to hydrogen embrittlement. The primary chemical distinction lies in the phosphorus content of DHP copper versus the oxygen content in ETP copper, influencing their respective mechanical and electrical properties.

Electrical Conductivity Comparison

DHP (Deoxidized High Phosphorus) copper offers electrical conductivity typically around 96% IACS (International Annealed Copper Standard), making it slightly less conductive than ETP (Electrolytic Tough Pitch) copper, which usually achieves about 101% IACS. The presence of phosphorus in DHP copper improves its deoxidizing properties and corrosion resistance but slightly reduces conductivity compared to the higher purity and oxygen content of ETP copper. ETP copper's superior electrical conductivity makes it the preferred choice for electrical wiring and conductors where maximum efficiency is critical.

Mechanical Properties: Strength and Ductility

DHP copper (Deoxidized High Phosphorus) offers enhanced strength and excellent ductility, making it suitable for applications requiring moderate mechanical resilience and good corrosion resistance. ETP copper (Electrolytic Tough Pitch) exhibits higher electrical conductivity but slightly lower strength and ductility compared to DHP copper, favoring applications where electrical performance is critical. The combined mechanical properties of DHP copper enable better formability and toughness in fabrication processes compared to ETP copper.

Corrosion Resistance and Durability

DHP Copper (Deoxidized High Phosphorus) offers superior corrosion resistance compared to ETP Copper (Electrolytic Tough Pitch) due to its phosphorus content, which enhances its ability to withstand water and steam environments. DHP Copper is preferred in plumbing and heat exchanger applications where durability and chemical resistance are critical. While ETP Copper provides excellent electrical conductivity, its corrosion resistance is generally lower, making DHP Copper the better choice for long-term durability in corrosive settings.

Suitability for Welding and Fabrication

DHP copper (Deoxidized High Phosphorus) offers superior weldability and is preferred for brazing and soldering due to its enhanced resistance to oxidation and improved fluidity. ETP copper (Electrolytic Tough Pitch) contains higher oxygen content, making it less ideal for welding processes as it can lead to porosity and embrittlement in joints. For fabrication requiring strong, reliable welds, DHP copper is the preferred choice, especially in plumbing and heat exchanger applications.

Typical Applications of DHP Copper

DHP (Deoxidized High Phosphorus) copper is widely used in applications requiring excellent corrosion resistance and enhanced mechanical strength, such as heat exchangers, condenser tubes, and plumbing fittings. Its phosphorus content improves resistance to hydrogen embrittlement, making it ideal for use in refrigeration and air conditioning systems. DHP copper's superior machinability and thermal conductivity also make it suitable for electrical connectors and automotive components.

Typical Applications of ETP Copper

ETP copper is widely used in electrical applications due to its high electrical conductivity and excellent corrosion resistance, making it ideal for manufacturing wires, cables, and electrical connectors. It is also commonly employed in plumbing systems and heat exchangers because of its durability and thermal conductivity. ETP copper's superior purity compared to DHP copper makes it the preferred choice for critical electrical components and industrial uses where reliability is paramount.

Cost Analysis: DHP Copper vs ETP Copper

DHP copper generally incurs higher production costs due to its phosphorus content, which enhances antimicrobial properties and mechanical strength, making it ideal for specialized applications. ETP copper is less expensive, as it undergoes minimal refining to achieve 99.9% purity, suitable for electrical and general purposes. Cost analysis reveals that DHP copper's premium price is justified by performance benefits in heat exchangers, whereas ETP copper offers cost-efficiency in bulk electrical wiring projects.

Choosing the Right Copper Material for Your Project

DHP copper, known for its high purity and excellent electrical conductivity, is often preferred in plumbing and HVAC applications due to its enhanced strength and corrosion resistance compared to ETP copper. ETP copper, with a minimum purity of 99.9%, excels in electrical wiring and electronic components requiring superior conductivity and ductility. Selecting the right copper material depends on project requirements such as mechanical strength, corrosion resistance, and electrical conductivity, where DHP copper suits structural uses and ETP copper fits high-performance electrical applications.

DHP Copper vs ETP Copper Infographic

materialdif.com

materialdif.com