Copper plating involves depositing a thin layer of copper onto a surface through electrochemical processes, enhancing conductivity and corrosion resistance. Copper coating applies a thicker layer, often using thermal spraying or chemical vapor deposition, providing robust protection and improved wear resistance. Both techniques boost surface properties, but plating is preferred for precision and electrical applications, while coating suits heavy-duty industrial uses.

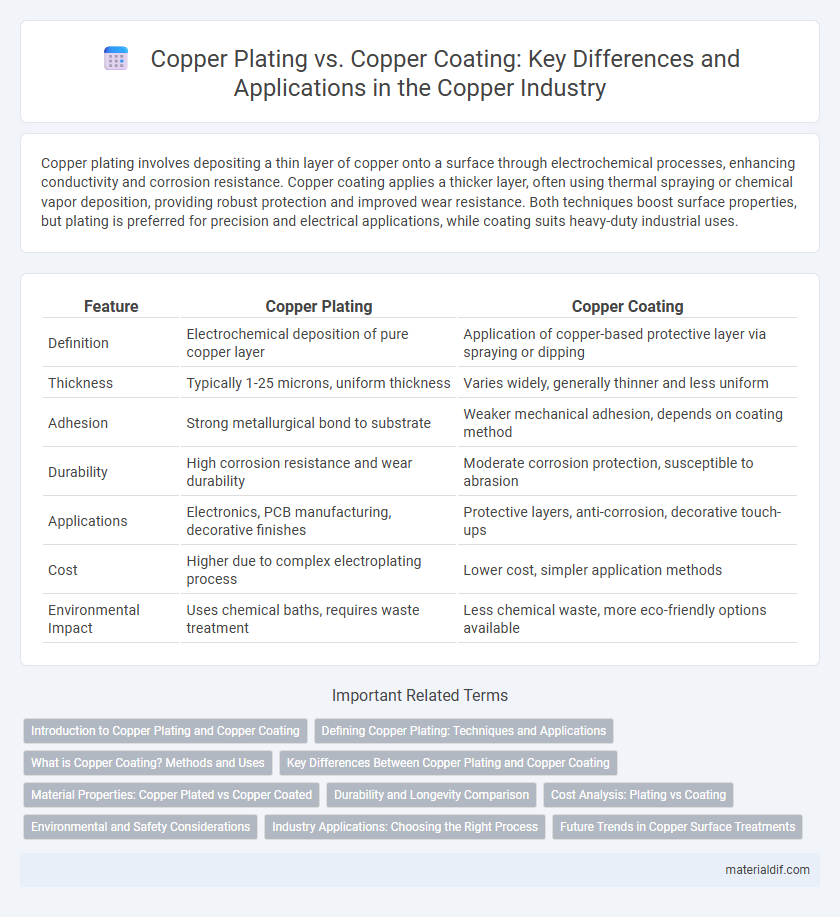

Table of Comparison

| Feature | Copper Plating | Copper Coating |

|---|---|---|

| Definition | Electrochemical deposition of pure copper layer | Application of copper-based protective layer via spraying or dipping |

| Thickness | Typically 1-25 microns, uniform thickness | Varies widely, generally thinner and less uniform |

| Adhesion | Strong metallurgical bond to substrate | Weaker mechanical adhesion, depends on coating method |

| Durability | High corrosion resistance and wear durability | Moderate corrosion protection, susceptible to abrasion |

| Applications | Electronics, PCB manufacturing, decorative finishes | Protective layers, anti-corrosion, decorative touch-ups |

| Cost | Higher due to complex electroplating process | Lower cost, simpler application methods |

| Environmental Impact | Uses chemical baths, requires waste treatment | Less chemical waste, more eco-friendly options available |

Introduction to Copper Plating and Copper Coating

Copper plating involves electrochemically depositing a layer of copper onto a substrate, enhancing electrical conductivity and corrosion resistance. Copper coating refers to applying copper by methods such as spraying, dipping, or brushing, offering surface protection and aesthetic appeal. Both processes improve metal durability but differ in thickness control, adhesion, and application technique.

Defining Copper Plating: Techniques and Applications

Copper plating involves depositing a thin layer of copper onto a substrate through electrochemical processes such as electroplating, electroless plating, or immersion plating, enhancing conductivity, corrosion resistance, and aesthetic appeal. Common applications include electronics manufacturing, where copper plating improves electrical performance and solderability, as well as decorative and industrial uses for wear resistance and heat dissipation. This technique differs from copper coating, which typically refers to applying copper-based paints or powders without establishing a metallic bond at the microscopic level.

What is Copper Coating? Methods and Uses

Copper coating involves applying a thin layer of copper onto a surface to enhance conductivity, corrosion resistance, and aesthetic appeal. Common methods include electroplating, chemical vapor deposition (CVD), and thermal spraying, each providing distinct thickness and adhesion properties tailored to industrial or decorative applications. Copper coatings are widely used in electronics for circuit boards, automotive parts for corrosion protection, and architectural elements for both functional and decorative purposes.

Key Differences Between Copper Plating and Copper Coating

Copper plating involves electrochemical deposition of a thin copper layer onto a metal substrate, ensuring uniform thickness and excellent adhesion for enhanced conductivity and corrosion resistance. Copper coating generally refers to the application of copper via thermal spraying or chemical methods, often resulting in thicker, less uniform layers primarily used for decorative or protective purposes. Key differences include the process technique, layer uniformity, adhesion strength, and typical applications, with copper plating favored in electronics and copper coating in industrial and decorative contexts.

Material Properties: Copper Plated vs Copper Coated

Copper plating involves an electrochemical process depositing a thin, uniform layer of pure copper onto a substrate, resulting in superior electrical conductivity and corrosion resistance. Copper coating typically applies a thicker, mechanically bonded layer with varied purity, offering enhanced durability but slightly reduced conductivity. The choice between copper plated and copper coated materials depends on balancing electrical performance with mechanical wear requirements.

Durability and Longevity Comparison

Copper plating offers superior durability due to its thicker layer and strong adhesion to the substrate, making it highly resistant to wear and corrosion. Copper coating, while thinner and less robust, provides basic protection and aesthetic appeal but tends to deteriorate faster under harsh environmental conditions. For applications requiring long-term performance, copper plating is the preferred choice, ensuring extended longevity and reliability.

Cost Analysis: Plating vs Coating

Copper plating typically involves electrochemical deposition, resulting in a uniform, durable metallic layer, while copper coating methods like spraying or dipping apply a thinner, less conductive surface layer. The cost of copper plating is generally higher due to the complexity of equipment, chemical baths, and labor involved, but it offers superior corrosion resistance and electrical conductivity. Copper coating, by contrast, is more cost-effective for large or irregular surfaces, requiring less processing time and lower material costs, though it may sacrifice longevity and performance quality.

Environmental and Safety Considerations

Copper plating uses electrochemical processes that often involve hazardous chemicals like cyanide or sulfuric acid, posing significant environmental disposal challenges and potential worker exposure risks. Copper coating methods, such as thermal spray or powder coating, typically reduce chemical waste and airborne toxins, improving workplace safety and minimizing ecological impact. Selecting copper coating over plating can lead to safer operational conditions and lower environmental contamination through reduced toxic effluents and emissions.

Industry Applications: Choosing the Right Process

Copper plating offers superior electrical conductivity and corrosion resistance, making it ideal for electronic components, circuit boards, and automotive parts requiring precise thickness control. Copper coating, often applied via thermal spraying or chemical vapor deposition, provides a cost-effective barrier against wear and oxidation in heavy machinery and architectural elements. Selecting between plating and coating depends on the specific industrial application's performance demands, surface characteristics, and budget constraints.

Future Trends in Copper Surface Treatments

Future trends in copper surface treatments emphasize advancements in copper plating and copper coating technologies driven by demand for enhanced corrosion resistance, electrical conductivity, and sustainability. Innovations include nano-structured copper plating for improved durability and eco-friendly, non-toxic copper coatings utilizing organic and hybrid materials for industrial and electronic applications. The integration of smart coatings with self-healing properties and enhanced adhesion further defines the trajectory of copper surface modifications.

Copper Plating vs Copper Coating Infographic

materialdif.com

materialdif.com