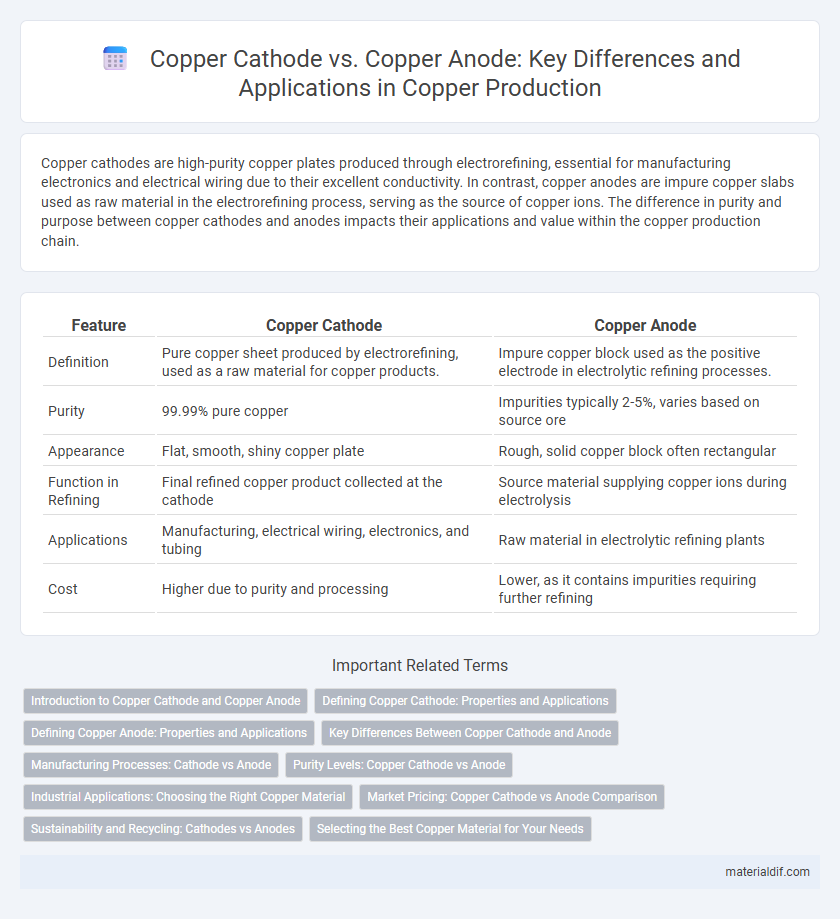

Copper cathodes are high-purity copper plates produced through electrorefining, essential for manufacturing electronics and electrical wiring due to their excellent conductivity. In contrast, copper anodes are impure copper slabs used as raw material in the electrorefining process, serving as the source of copper ions. The difference in purity and purpose between copper cathodes and anodes impacts their applications and value within the copper production chain.

Table of Comparison

| Feature | Copper Cathode | Copper Anode |

|---|---|---|

| Definition | Pure copper sheet produced by electrorefining, used as a raw material for copper products. | Impure copper block used as the positive electrode in electrolytic refining processes. |

| Purity | 99.99% pure copper | Impurities typically 2-5%, varies based on source ore |

| Appearance | Flat, smooth, shiny copper plate | Rough, solid copper block often rectangular |

| Function in Refining | Final refined copper product collected at the cathode | Source material supplying copper ions during electrolysis |

| Applications | Manufacturing, electrical wiring, electronics, and tubing | Raw material in electrolytic refining plants |

| Cost | Higher due to purity and processing | Lower, as it contains impurities requiring further refining |

Introduction to Copper Cathode and Copper Anode

Copper cathodes are high-purity copper sheets produced through the electrorefining process, serving as the primary input for manufacturing copper products and electrical wiring. Copper anodes, typically cast from impure copper blister, function as the starting material in electrorefining, where they undergo purification to form cathodes. The distinction lies in their roles during refining: anodes are impure copper sources, and cathodes are the refined, nearly pure copper outputs essential for industrial applications.

Defining Copper Cathode: Properties and Applications

Copper cathode is a high-purity form of copper produced through electrolytic refining, typically achieving purity levels of 99.99%. It features excellent electrical conductivity, corrosion resistance, and malleability, making it ideal for electrical wiring, electronics, and high-quality copper products. Copper cathodes serve as the primary raw material for manufacturing wires, cables, and various copper alloys used in construction and industrial applications.

Defining Copper Anode: Properties and Applications

Copper anodes are thick plates of high-purity copper, typically 99.99% pure, used predominantly in the electrolytic refining process to produce copper cathodes. These anodes exhibit excellent electrical conductivity, corrosion resistance, and mechanical strength, making them ideal for efficient copper extraction and metal plating applications. Their primary application lies in the electrorefining and electroplating industries, where they serve as the source material for producing ultra-pure copper sheets and coatings.

Key Differences Between Copper Cathode and Anode

Copper cathodes are highly pure sheets of copper, typically 99.99% pure, produced through electrorefining, while copper anodes consist of impure copper used as the raw material in this refining process. The primary difference lies in their function: copper anodes serve as the source of impure copper that dissolves during electrolysis, whereas cathodes collect the purified copper deposited on their surface. Cathodes are the final refined product ready for industrial use, whereas anodes are intermediate materials requiring further processing.

Manufacturing Processes: Cathode vs Anode

Copper cathodes are produced through electrolytic refining, where impure copper anodes are dissolved in an acidic solution, allowing pure copper to deposit onto cathode sheets. The manufacturing of copper anodes involves casting molten copper into large slabs or plates, which serve as the starting material for refining. While anodes contain impurities and require further processing, cathodes represent high-purity copper ready for industrial use.

Purity Levels: Copper Cathode vs Anode

Copper cathodes typically exhibit purity levels of 99.99%, making them the preferred choice for industrial applications requiring high conductivity and corrosion resistance. In contrast, copper anodes usually have a slightly lower purity, around 99.5%, as they contain impurities removed during the refining process. The higher purity of cathodes ensures enhanced performance in electrical wiring, electronics manufacturing, and chemical applications.

Industrial Applications: Choosing the Right Copper Material

Copper cathodes, produced through electrolytic refining, offer high purity levels ideal for manufacturing electrical wiring, electronics, and intricate industrial components requiring excellent conductivity. Copper anodes, typically less refined and used as feedstock in the electrorefining process, are essential in industries focused on copper purification and recycling. Selecting the appropriate copper material depends on the application's purity requirements and processing stage, with cathodes favored for precise industrial applications and anodes for bulk refining processes.

Market Pricing: Copper Cathode vs Anode Comparison

Copper cathodes typically command a higher market price than copper anodes due to their higher purity levels, usually exceeding 99.99%, making them ideal for direct use in manufacturing and refining processes. In contrast, copper anodes, containing impurities, are primarily used in electrolytic refining, which adds processing costs that influence their lower market value. The pricing gap between cathodes and anodes reflects differences in processing stages, purity requirements, and end-use applications within the copper supply chain.

Sustainability and Recycling: Cathodes vs Anodes

Copper cathodes, produced through electrorefining, exhibit higher purity levels, enhancing their recyclability and reducing environmental impact in subsequent manufacturing. Copper anodes, containing impurities, require energy-intensive refining processes, increasing carbon emissions and waste generation. Prioritizing copper cathode recycling significantly supports sustainable metal management by minimizing resource extraction and promoting circular economy practices.

Selecting the Best Copper Material for Your Needs

Copper cathodes offer high purity, typically 99.99%, making them ideal for applications requiring minimal impurities and superior electrical conductivity. Copper anodes, with impurities intentionally retained, are best suited for refining processes and electroplating where controlled oxidation is necessary. Selecting the best copper material depends on whether your priority is optimal purity and conductivity (cathode) or refining and electrochemical performance (anode).

Copper Cathode vs Copper Anode Infographic

materialdif.com

materialdif.com