Electrolytic refining of copper produces higher purity metal by using an electrolytic cell to dissolve impure copper anodes and deposit pure copper on cathodes, enhancing conductivity and corrosion resistance. Fire refining, in contrast, involves heating impure copper in a furnace to remove impurities through oxidation and slag formation but typically results in lower purity levels and is less precise. Choosing between electrolytic and fire refining depends on the desired copper purity and application requirements.

Table of Comparison

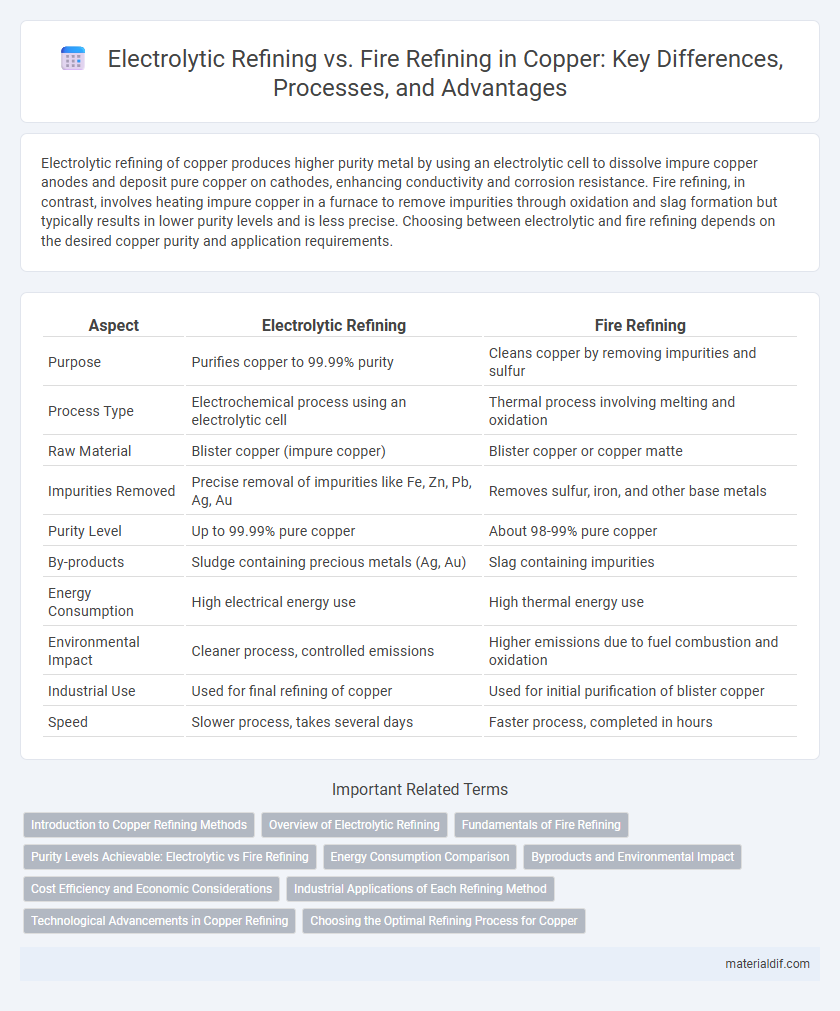

| Aspect | Electrolytic Refining | Fire Refining |

|---|---|---|

| Purpose | Purifies copper to 99.99% purity | Cleans copper by removing impurities and sulfur |

| Process Type | Electrochemical process using an electrolytic cell | Thermal process involving melting and oxidation |

| Raw Material | Blister copper (impure copper) | Blister copper or copper matte |

| Impurities Removed | Precise removal of impurities like Fe, Zn, Pb, Ag, Au | Removes sulfur, iron, and other base metals |

| Purity Level | Up to 99.99% pure copper | About 98-99% pure copper |

| By-products | Sludge containing precious metals (Ag, Au) | Slag containing impurities |

| Energy Consumption | High electrical energy use | High thermal energy use |

| Environmental Impact | Cleaner process, controlled emissions | Higher emissions due to fuel combustion and oxidation |

| Industrial Use | Used for final refining of copper | Used for initial purification of blister copper |

| Speed | Slower process, takes several days | Faster process, completed in hours |

Introduction to Copper Refining Methods

Copper refining methods primarily include electrolytic refining and fire refining, each serving distinct purposes in purifying copper metal. Electrolytic refining employs an electrolytic cell where impure copper anodes dissolve and pure copper cathodes are deposited, achieving high purity levels above 99.99%. Fire refining involves oxidizing impurities in molten copper to separate them as slag, commonly used before electrolytic refining to prepare blister copper.

Overview of Electrolytic Refining

Electrolytic refining of copper involves using an electrolytic cell where impure copper acts as the anode and pure copper plates onto the cathode, resulting in high-purity copper with impurities either falling off as anode slime or remaining in solution. This process achieves copper purity levels of 99.99%, essential for electrical applications requiring excellent conductivity. Unlike fire refining, which relies on melting and oxidation, electrolytic refining offers better precision and environmental control for producing ultra-pure copper.

Fundamentals of Fire Refining

Fire refining involves heating blister copper to remove impurities such as sulfur and iron by oxidation in a reverberatory furnace. The process relies on controlled air blowing to convert impurities into slag while preserving copper content. Electrolytic refining further purifies copper by using an electrochemical cell, producing high-purity cathode copper with up to 99.99% purity, surpassing the typical 98-99% purity achieved in fire refining.

Purity Levels Achievable: Electrolytic vs Fire Refining

Electrolytic refining of copper can achieve purity levels of 99.99%, making it the preferred method for producing high-grade copper used in electrical wiring and electronics. Fire refining typically yields copper with purity around 98-99%, suitable for applications where slightly lower purity is acceptable. The advanced electrochemical process in electrolytic refining ensures removal of most impurities, including precious metals like silver and gold, resulting in superior purity compared to the thermal oxidation used in fire refining.

Energy Consumption Comparison

Electrolytic refining of copper consumes significantly less energy than fire refining, due to its lower thermal requirements and the use of electrical current to purify the metal. Fire refining relies on high-temperature processes that demand substantial fuel or electricity to maintain molten conditions and remove impurities. As a result, electrolytic refining is preferred for energy-efficient copper production, contributing to lower operational costs and reduced environmental impact.

Byproducts and Environmental Impact

Electrolytic refining of copper produces high-purity cathodes and generates valuable byproducts such as precious metals (gold, silver) and sulfuric acid, which can be captured and reused, minimizing waste. Fire refining emits more sulfur dioxide and heavy metals, contributing significantly to air pollution and requiring complex gas treatment systems to reduce environmental harm. The electrolytic process is favored for its lower environmental footprint and efficient recovery of byproducts, supporting sustainable copper production.

Cost Efficiency and Economic Considerations

Electrolytic refining of copper offers superior cost efficiency through higher purity output and lower energy consumption compared to fire refining, which requires more fuel and labor-intensive processes. Economic considerations favor electrolytic refining due to its scalability, reduced waste generation, and ability to recover valuable by-products, resulting in improved overall profitability. Despite higher initial capital investment, electrolytic refining's operational savings and product quality enhance long-term economic viability over fire refining methods.

Industrial Applications of Each Refining Method

Electrolytic refining of copper is predominantly used in industrial applications that require high-purity copper, such as electrical wiring, electronics manufacturing, and high-grade alloys, due to its ability to produce copper with purities exceeding 99.99%. Fire refining is typically applied in large-scale smelting operations to remove impurities from blister copper before casting, making it suitable for industries focused on bulk copper production with moderate purity requirements. The choice between electrolytic and fire refining depends on the desired copper purity and the scale of industrial application, with electrolytic refining favored for precision-demanding sectors.

Technological Advancements in Copper Refining

Electrolytic refining has advanced significantly with improved electrode design and automated control systems, resulting in higher purity copper reaching 99.99% copper content compared to traditional fire refining. Innovations in electrolysis cells optimize energy consumption and reduce impurities such as iron and sulfur more effectively than fire refining. These technological developments enable large-scale, environmentally sustainable production with consistent quality demanded by modern electronics and electrical industries.

Choosing the Optimal Refining Process for Copper

Electrolytic refining produces high-purity copper, typically above 99.99%, making it ideal for electrical applications requiring superior conductivity. Fire refining is faster and more cost-effective for initial purification, effectively removing impurities like iron and sulfur but yielding lower purity levels. Selecting the optimal refining process depends on the desired copper grade and end-use, with electrolytic refining favored for premium copper and fire refining suitable for bulk processing.

Electrolytic Refining vs Fire Refining Infographic

materialdif.com

materialdif.com