Copper mesh offers superior flexibility and enhanced ventilation compared to copper plates, making it ideal for applications requiring airflow and lightweight shielding. Copper plates provide greater strength, durability, and consistent electrical conductivity, suited for structural components and heavy-duty electrical contacts. Choosing between copper mesh and copper plates depends on the specific needs for flexibility, strength, and conductivity in your project.

Table of Comparison

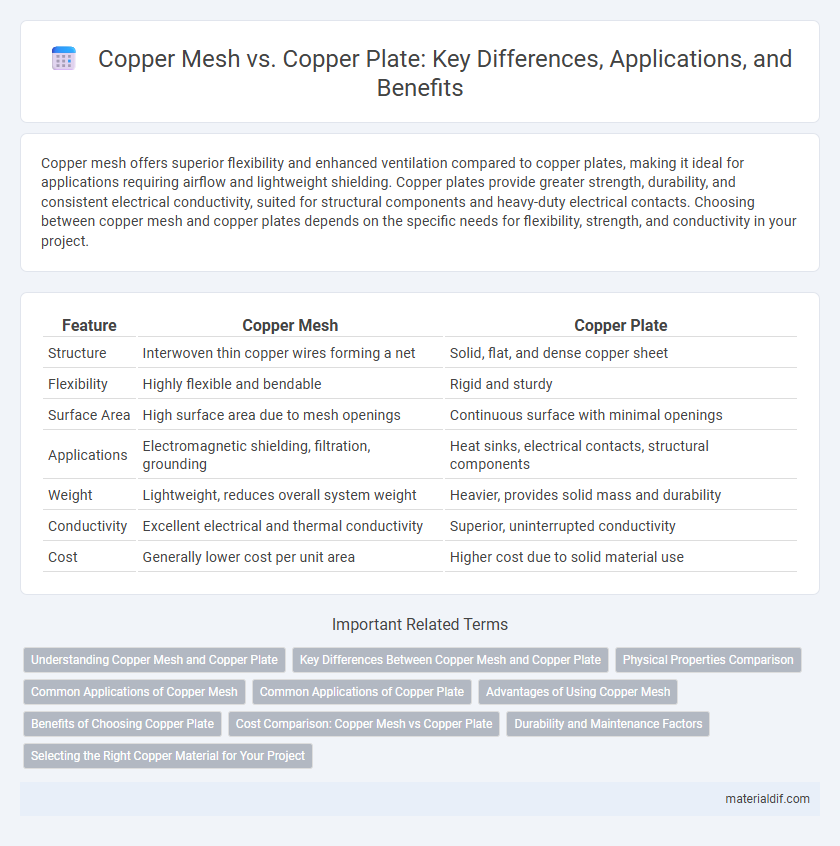

| Feature | Copper Mesh | Copper Plate |

|---|---|---|

| Structure | Interwoven thin copper wires forming a net | Solid, flat, and dense copper sheet |

| Flexibility | Highly flexible and bendable | Rigid and sturdy |

| Surface Area | High surface area due to mesh openings | Continuous surface with minimal openings |

| Applications | Electromagnetic shielding, filtration, grounding | Heat sinks, electrical contacts, structural components |

| Weight | Lightweight, reduces overall system weight | Heavier, provides solid mass and durability |

| Conductivity | Excellent electrical and thermal conductivity | Superior, uninterrupted conductivity |

| Cost | Generally lower cost per unit area | Higher cost due to solid material use |

Understanding Copper Mesh and Copper Plate

Copper mesh consists of finely woven strands that provide high electrical conductivity and excellent flexibility, making it ideal for electromagnetic interference shielding and grounding applications. Copper plates are solid, flat sheets offering superior mechanical strength, corrosion resistance, and thermal conductivity, commonly used in electrical busbars, heat exchangers, and structural components. Choosing between copper mesh and copper plate depends on the need for flexibility versus rigidity and the specific electrical or thermal requirements of the application.

Key Differences Between Copper Mesh and Copper Plate

Copper mesh features a flexible, woven structure that allows for superior airflow and electromagnetic interference (EMI) shielding, commonly used in electronic enclosures. Copper plate, characterized by its solid, flat surface, provides excellent thermal conductivity and mechanical strength, ideal for heat sinks and structural applications. The choice between copper mesh and copper plate depends on the specific requirements for flexibility, conductivity, and mechanical durability in a given project.

Physical Properties Comparison

Copper mesh exhibits a flexible and porous structure, allowing for superior airflow and heat dissipation compared to copper plates, which are solid and rigid with higher density and thermal conductivity. The mesh's tensile strength is typically lower than that of the copper plate, making plates more suitable for applications requiring mechanical durability and electrical conductivity. Copper plates have a higher mass per unit area, enhancing their effectiveness in shielding and structural uses, while meshes are preferred for filtration and ventilation due to their lightweight and permeable physical properties.

Common Applications of Copper Mesh

Copper mesh is widely used in electromagnetic interference (EMI) shielding, filtration systems, and grounding applications due to its flexibility and high conductivity. Its porous structure makes it ideal for efficient airflow and liquid filtering in industrial processes, while also providing effective shielding in electronic devices. In contrast, copper plates are preferred for structural components and heat dissipation where rigid, solid surfaces are required.

Common Applications of Copper Plate

Copper plates are widely used in electrical engineering for busbars, grounding systems, and heat sinks due to their excellent conductivity and thermal performance. Their durability and ease of fabrication make them ideal for industrial applications such as roofing, cladding, and marine hardware. In comparison, copper mesh is typically employed for electromagnetic shielding and filtration, while copper plates serve structural and conductive purposes.

Advantages of Using Copper Mesh

Copper mesh offers superior flexibility and adaptability compared to copper plates, allowing it to conform easily to irregular surfaces and complex shapes. Its porous structure provides enhanced airflow and drainage, making it ideal for applications in EMI shielding, filtration, and grounding. Copper mesh also reduces overall weight while maintaining excellent electrical conductivity and corrosion resistance.

Benefits of Choosing Copper Plate

Copper plate offers superior durability and enhanced electrical conductivity compared to copper mesh, making it ideal for applications requiring consistent performance and long-term reliability. Its solid structure provides excellent thermal management and corrosion resistance, which is crucial in industrial and electronic uses. Copper plate's uniform thickness ensures precise machining and ease of fabrication, optimizing efficiency in manufacturing processes.

Cost Comparison: Copper Mesh vs Copper Plate

Copper mesh generally costs less than copper plate due to its lower material density and manufacturing complexity, making it ideal for applications requiring conductivity with reduced weight. Copper plates, being solid and thicker, have higher raw material costs and machining expenses, which elevate their price significantly over mesh forms. Choosing between copper mesh and plate depends on budget constraints alongside specific performance needs such as strength, surface area, and conductivity.

Durability and Maintenance Factors

Copper mesh offers enhanced flexibility and corrosion resistance, making it ideal for applications requiring adaptability and prolonged exposure to harsh environments. Copper plates provide superior structural durability and ease of maintenance due to their solid form and smoother surfaces that resist wear and simplify cleaning. Choosing between copper mesh and copper plate depends on the balance between mechanical strength and the need for ventilation or filtration in specific industrial uses.

Selecting the Right Copper Material for Your Project

Copper mesh offers superior flexibility and excellent airflow, making it ideal for electromagnetic shielding and filtration applications. Copper plates provide enhanced durability and structural strength, suited for heavy-duty electrical and thermal conduction projects. Selecting the right copper material depends on project requirements such as mechanical strength, conductivity, and environmental exposure.

Copper Mesh vs Copper Plate Infographic

materialdif.com

materialdif.com