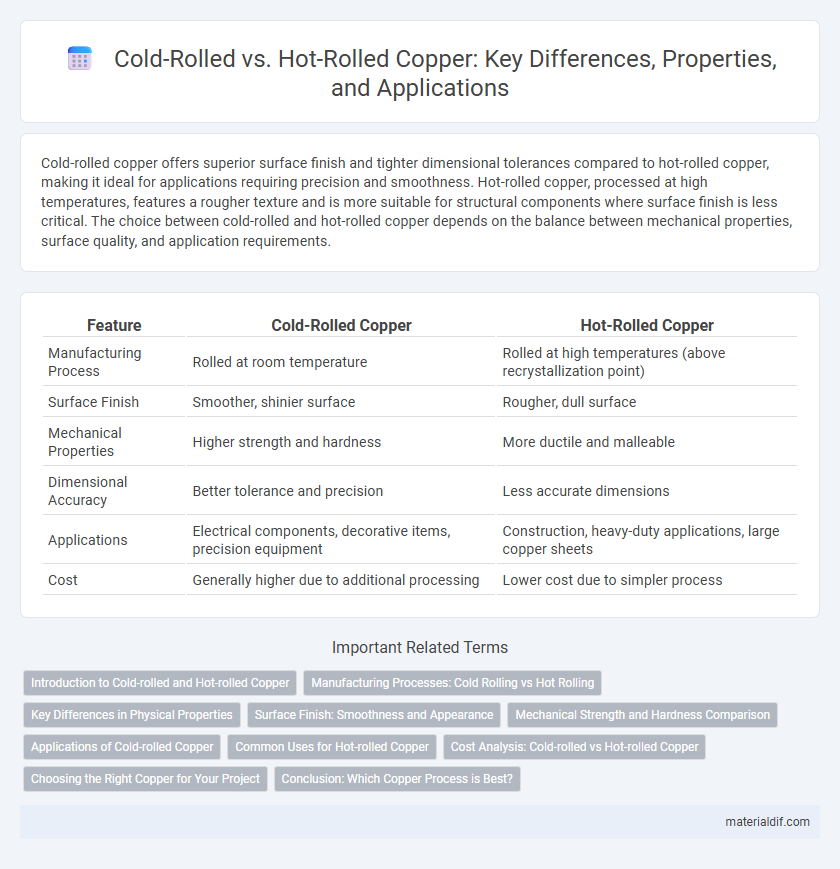

Cold-rolled copper offers superior surface finish and tighter dimensional tolerances compared to hot-rolled copper, making it ideal for applications requiring precision and smoothness. Hot-rolled copper, processed at high temperatures, features a rougher texture and is more suitable for structural components where surface finish is less critical. The choice between cold-rolled and hot-rolled copper depends on the balance between mechanical properties, surface quality, and application requirements.

Table of Comparison

| Feature | Cold-Rolled Copper | Hot-Rolled Copper |

|---|---|---|

| Manufacturing Process | Rolled at room temperature | Rolled at high temperatures (above recrystallization point) |

| Surface Finish | Smoother, shinier surface | Rougher, dull surface |

| Mechanical Properties | Higher strength and hardness | More ductile and malleable |

| Dimensional Accuracy | Better tolerance and precision | Less accurate dimensions |

| Applications | Electrical components, decorative items, precision equipment | Construction, heavy-duty applications, large copper sheets |

| Cost | Generally higher due to additional processing | Lower cost due to simpler process |

Introduction to Cold-rolled and Hot-rolled Copper

Cold-rolled copper undergoes a finishing process at room temperature, enhancing its surface finish, dimensional accuracy, and mechanical strength through strain hardening. Hot-rolled copper is processed at high temperatures above its recrystallization point, resulting in improved ductility and uniform grain structure with a rougher surface texture. The choice between cold-rolled and hot-rolled copper depends on the desired balance between strength, surface quality, and formability for specific industrial applications.

Manufacturing Processes: Cold Rolling vs Hot Rolling

Cold-rolled copper undergoes deformation at room temperature, resulting in a smoother surface finish and increased strength due to strain hardening, making it ideal for precision applications. Hot-rolled copper is processed at temperatures above recrystallization, allowing for easier shaping and reduced internal stresses but producing a rougher surface finish. The choice between cold rolling and hot rolling impacts the copper's mechanical properties, texture, and suitability for specific industrial uses.

Key Differences in Physical Properties

Cold-rolled copper exhibits higher tensile strength and improved surface finish compared to hot-rolled copper due to work hardening during the rolling process. Hot-rolled copper typically has a rougher texture with greater ductility and is more suitable for applications requiring extensive forming or shaping. The grain structure in cold-rolled copper is more refined, enhancing its mechanical properties and electrical conductivity over hot-rolled variants.

Surface Finish: Smoothness and Appearance

Cold-rolled copper exhibits a smoother surface finish and more refined appearance due to the controlled rolling process at room temperature, resulting in minimal oxidation and tighter tolerances. Hot-rolled copper, processed at elevated temperatures, typically shows a rougher texture with scale and discoloration, which may require further surface treatment for aesthetic applications. The superior surface quality of cold-rolled copper makes it ideal for decorative and electrical uses where visual appeal and precise dimensions are critical.

Mechanical Strength and Hardness Comparison

Cold-rolled copper exhibits higher mechanical strength and greater hardness compared to hot-rolled copper due to the work hardening effect during the rolling process. Hot-rolled copper, processed at elevated temperatures, maintains a softer and more ductile structure, resulting in lower tensile strength and hardness values. The enhanced mechanical properties of cold-rolled copper make it ideal for applications requiring superior durability and wear resistance.

Applications of Cold-rolled Copper

Cold-rolled copper exhibits superior surface finish and precise dimensional tolerances, making it ideal for applications in electrical connectors, electronic components, and intricate architectural details. Its enhanced mechanical strength and corrosion resistance suit cold-rolled copper for use in HVAC systems, automotive radiators, and heat exchangers. Industries prioritize cold-rolled copper for manufacturing components that require high conductivity combined with durability and aesthetic appeal.

Common Uses for Hot-rolled Copper

Hot-rolled copper is commonly utilized in construction, electrical applications, and plumbing due to its excellent ductility and strength. It is preferred for manufacturing sheets, plates, and structural components that require enhanced mechanical properties and durability. This form of copper also finds widespread use in heat exchangers and industrial machinery where thermal conductivity and corrosion resistance are critical.

Cost Analysis: Cold-rolled vs Hot-rolled Copper

Cold-rolled copper typically incurs higher production costs due to the additional processing steps that increase material strength and surface finish quality. Hot-rolled copper is generally more cost-effective for large-scale applications, as the process is faster and requires less energy, though it yields a rougher surface suitable for less precision-demanding uses. Choosing between cold-rolled and hot-rolled copper hinges on balancing budget constraints with required material properties and final application specifications.

Choosing the Right Copper for Your Project

Cold-rolled copper offers superior surface finish and tighter dimensional tolerances, making it ideal for applications requiring precision and aesthetic appeal. Hot-rolled copper provides greater malleability and cost-efficiency, suitable for structural projects or those involving extensive shaping. Selecting between cold-rolled and hot-rolled copper depends on the specific requirements of strength, appearance, and budget in your project.

Conclusion: Which Copper Process is Best?

Cold-rolled copper offers superior surface finish, tighter tolerances, and increased strength, making it ideal for applications requiring precision and aesthetic quality. Hot-rolled copper is more cost-effective for large-scale projects where dimensional accuracy is less critical and better ductility is desired. Selection depends on specific application needs, with cold-rolled favored for high-performance and detailed work, while hot-rolled suits heavy-duty, flexible copper requirements.

Cold-rolled Copper vs Hot-rolled Copper Infographic

materialdif.com

materialdif.com