Copper rod extrusion and copper wire drawing are two distinct metal forming processes used in the production of copper products. Copper rod extrusion involves forcing heated copper billet through a die to produce a continuous rod with a uniform cross-section, ideal for creating larger diameter rods with improved mechanical properties. In contrast, copper wire drawing pulls the copper rod through progressively smaller dies to reduce its diameter and increase its length, resulting in fine wires used in electrical and telecommunications applications.

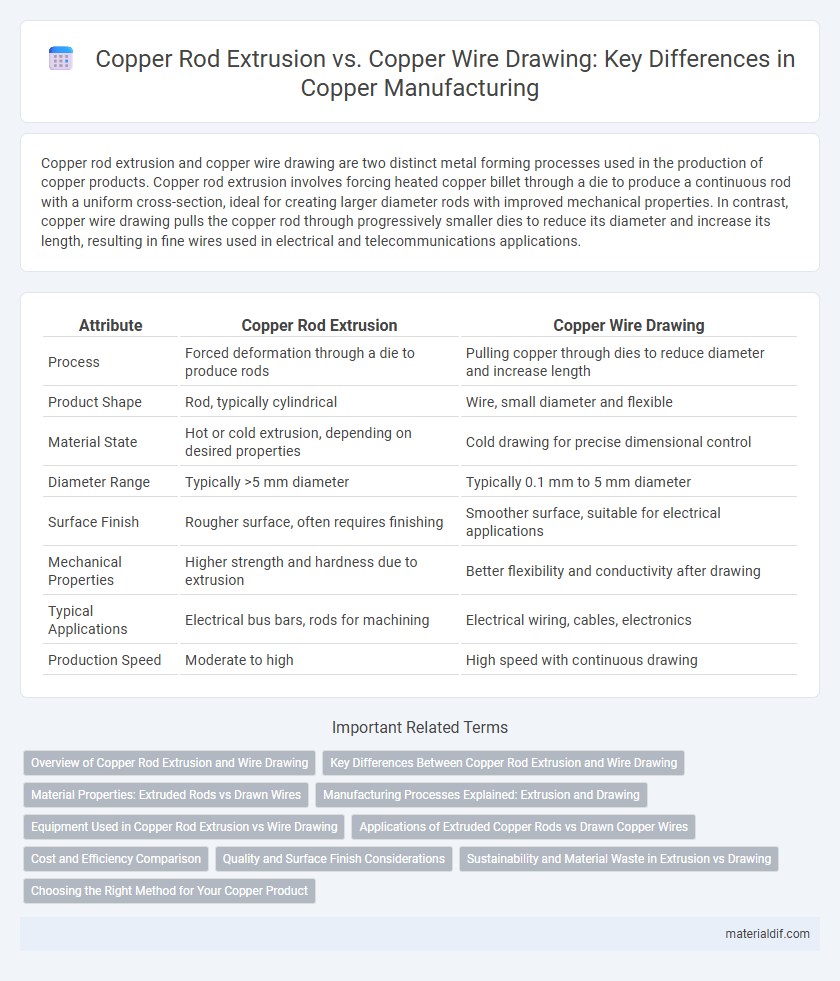

Table of Comparison

| Attribute | Copper Rod Extrusion | Copper Wire Drawing |

|---|---|---|

| Process | Forced deformation through a die to produce rods | Pulling copper through dies to reduce diameter and increase length |

| Product Shape | Rod, typically cylindrical | Wire, small diameter and flexible |

| Material State | Hot or cold extrusion, depending on desired properties | Cold drawing for precise dimensional control |

| Diameter Range | Typically >5 mm diameter | Typically 0.1 mm to 5 mm diameter |

| Surface Finish | Rougher surface, often requires finishing | Smoother surface, suitable for electrical applications |

| Mechanical Properties | Higher strength and hardness due to extrusion | Better flexibility and conductivity after drawing |

| Typical Applications | Electrical bus bars, rods for machining | Electrical wiring, cables, electronics |

| Production Speed | Moderate to high | High speed with continuous drawing |

Overview of Copper Rod Extrusion and Wire Drawing

Copper rod extrusion involves forcing heated copper billets through a die to create long rods with consistent cross-sections, offering superior mechanical properties and surface finish. Copper wire drawing pulls copper rods through progressively smaller dies, reducing diameter and elongating the wire while improving tensile strength and electrical conductivity. Both processes are essential in producing copper products for electrical wiring, with extrusion prioritizing shape uniformity and drawing emphasizing precise diameter control.

Key Differences Between Copper Rod Extrusion and Wire Drawing

Copper rod extrusion involves pushing or forcing molten copper through a die to create long, cylindrical rods with consistent cross-sectional shapes, ideal for high-strength applications and seamless surfaces. In contrast, copper wire drawing pulls copper rods through progressively smaller dies to reduce diameter and improve tensile strength and flexibility, commonly used for electrical wiring and fine wire production. The extrusion process emphasizes shape accuracy and structural integrity, whereas wire drawing prioritizes diameter precision and material ductility.

Material Properties: Extruded Rods vs Drawn Wires

Copper rod extrusion results in a product with a more uniform grain structure and improved mechanical strength compared to drawn wires, which typically exhibit higher tensile strength and greater surface finish due to work hardening during the drawing process. Extruded copper rods maintain excellent electrical conductivity and ductility, making them suitable for applications requiring robust performance under stress. Drawn copper wires, characterized by enhanced flexibility and reduced diameter, are optimized for intricate electrical wiring and precision components where detailed geometry is critical.

Manufacturing Processes Explained: Extrusion and Drawing

Copper rod extrusion involves forcing heated copper billets through a die to produce uniform rods with precise cross-sectional shapes, optimizing grain structure and mechanical strength. In contrast, copper wire drawing pulls copper rods through progressively smaller dies at room temperature, enhancing tensile strength and surface finish by strain hardening. Both processes are essential in manufacturing copper products, with extrusion suited for larger cross-sections and drawing preferred for thin, flexible wires used in electrical applications.

Equipment Used in Copper Rod Extrusion vs Wire Drawing

Copper rod extrusion utilizes powerful hydraulic presses and specialized extrusion dies to shape copper billets into continuous rod forms, requiring robust equipment capable of withstanding high forces and temperatures. In contrast, copper wire drawing employs a sequence of drawing dies and capstans to progressively reduce the diameter of copper rods into fine wires, relying on precision machinery to maintain dimensional accuracy and surface finish. Both processes use advanced lubrication systems to minimize friction and extend die life, but wire drawing demands more intricate tension control equipment for uniform wire thickness.

Applications of Extruded Copper Rods vs Drawn Copper Wires

Copper rod extrusion produces uniform, high-strength rods ideal for heavy-duty electrical busbars, grounding systems, and manufacturing of copper pipes due to its superior cross-sectional consistency. In contrast, copper wire drawing enables the production of finer, flexible wires used extensively in telecommunications, electrical wiring, and intricate coil windings. Extruded rods offer enhanced mechanical stability for structural applications, while drawn wires provide excellent conductivity and flexibility for detailed electrical components.

Cost and Efficiency Comparison

Copper rod extrusion typically involves higher initial costs due to the need for specialized extrusion presses and dies, while copper wire drawing generally offers lower operational expenses with simpler equipment and processes. Wire drawing achieves greater material utilization and produces finer cross-sectional diameters, enhancing efficiency in producing high-precision wires. The trade-off between extrusion's ability to create complex profiles and wire drawing's cost-effective high-volume output defines their economic and efficiency balance.

Quality and Surface Finish Considerations

Copper rod extrusion produces a consistent, dense microstructure essential for high mechanical strength, resulting in superior surface finish with minimal defects compared to copper wire drawing. Wire drawing often introduces surface irregularities and work hardening effects, requiring additional annealing processes to enhance ductility and surface quality. Precision in extrusion controls diameter tolerance and reduces surface roughness, making it preferable for applications demanding optimal conductivity and aesthetic appeal in copper components.

Sustainability and Material Waste in Extrusion vs Drawing

Copper rod extrusion generates less material waste compared to copper wire drawing due to its continuous shaping process, reducing scrap and energy consumption. Wire drawing, while precise for thinner gauges, involves more significant material loss from multiple stages of pulling and annealing. Sustainable copper manufacturing favors extrusion for its efficiency, lower carbon footprint, and improved material utilization.

Choosing the Right Method for Your Copper Product

Selecting between copper rod extrusion and copper wire drawing depends on the desired product shape and mechanical properties. Copper rod extrusion is ideal for producing uniform, straight rods with enhanced strength and dimensional control, suitable for structural applications. Copper wire drawing excels in creating fine, flexible wires with precise diameter control, perfect for electrical conductivity and complex winding requirements.

Copper Rod Extrusion vs Copper Wire Drawing Infographic

materialdif.com

materialdif.com