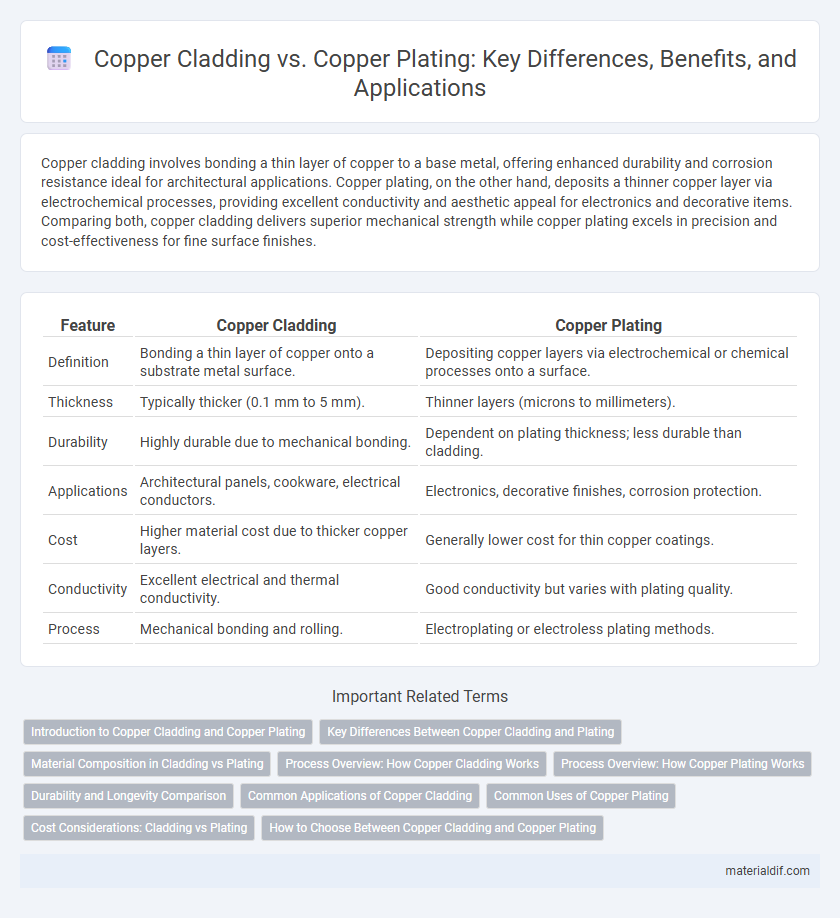

Copper cladding involves bonding a thin layer of copper to a base metal, offering enhanced durability and corrosion resistance ideal for architectural applications. Copper plating, on the other hand, deposits a thinner copper layer via electrochemical processes, providing excellent conductivity and aesthetic appeal for electronics and decorative items. Comparing both, copper cladding delivers superior mechanical strength while copper plating excels in precision and cost-effectiveness for fine surface finishes.

Table of Comparison

| Feature | Copper Cladding | Copper Plating |

|---|---|---|

| Definition | Bonding a thin layer of copper onto a substrate metal surface. | Depositing copper layers via electrochemical or chemical processes onto a surface. |

| Thickness | Typically thicker (0.1 mm to 5 mm). | Thinner layers (microns to millimeters). |

| Durability | Highly durable due to mechanical bonding. | Dependent on plating thickness; less durable than cladding. |

| Applications | Architectural panels, cookware, electrical conductors. | Electronics, decorative finishes, corrosion protection. |

| Cost | Higher material cost due to thicker copper layers. | Generally lower cost for thin copper coatings. |

| Conductivity | Excellent electrical and thermal conductivity. | Good conductivity but varies with plating quality. |

| Process | Mechanical bonding and rolling. | Electroplating or electroless plating methods. |

Introduction to Copper Cladding and Copper Plating

Copper cladding involves bonding a thin layer of copper to a base metal, providing enhanced corrosion resistance and electrical conductivity without the need for a fully copper construction. Copper plating, on the other hand, deposits a thin copper layer via electrochemical or electroless processes, resulting in a uniform, controlled coating ideal for decorative and functional purposes. Both methods optimize copper's beneficial properties, but cladding typically offers greater mechanical durability while plating allows for precise thickness control.

Key Differences Between Copper Cladding and Plating

Copper cladding involves bonding a thick layer of copper to a substrate, enhancing durability and corrosion resistance, while copper plating deposits a thin copper layer through electrochemical or chemical processes, primarily for aesthetic and moderate protective purposes. Cladding provides superior mechanical strength and is ideal for architectural applications, whereas plating is commonly used for electronics and decorative finishes due to its economic use of copper. The key differences lie in layer thickness, bonding technique, and application areas, influencing performance and cost-effectiveness.

Material Composition in Cladding vs Plating

Copper cladding involves bonding a thick layer of pure copper onto a base metal such as steel or aluminum, providing enhanced corrosion resistance and conductivity due to the substantial copper layer. Copper plating, by contrast, applies a much thinner coating of copper via electroplating or electroless plating processes, resulting in a smaller quantity of copper material on the substrate. The material composition in copper cladding ensures structural strength and durability, while copper plating offers precise surface finishing and aesthetic appeal with minimal copper usage.

Process Overview: How Copper Cladding Works

Copper cladding involves bonding a thin layer of copper to a substrate metal through methods such as explosive welding or roll bonding, creating a composite material with enhanced electrical and thermal conductivity. This process ensures a strong metallurgical bond without melting the metals, maintaining the substrate's structural integrity while adding copper's corrosion resistance. Copper plating, by contrast, deposits copper electrolytically or chemically, resulting in a thinner, less robust surface layer primarily for decorative or mild protective purposes.

Process Overview: How Copper Plating Works

Copper plating involves depositing a thin layer of copper onto a substrate through an electrochemical process where the object serves as the cathode in an electrolytic cell. This method allows precise control over the thickness and uniformity of the copper layer, making it suitable for electronic components and intricate designs. Unlike copper cladding, which bonds thicker copper sheets to materials, plating offers enhanced corrosion resistance and improved electrical conductivity at a microscale level.

Durability and Longevity Comparison

Copper cladding offers superior durability compared to copper plating due to its thicker layer of pure copper, providing enhanced resistance to corrosion, weathering, and physical wear. Copper plating, with its thinner copper deposit, tends to wear off faster under abrasive conditions, reducing its effective lifespan. Over time, copper cladding maintains its aesthetic and protective qualities longer, making it the preferred choice for applications requiring extended longevity.

Common Applications of Copper Cladding

Copper cladding is widely used in architectural applications, providing durable and aesthetic metal surfaces for roofing, facades, and interior wall panels. Its robust corrosion resistance and natural patina make it ideal for historic restoration projects and modern commercial buildings. Copper cladding also serves as an effective protective layer for steel structures, enhancing longevity while offering a distinctive copper appearance.

Common Uses of Copper Plating

Copper plating is widely used for its excellent electrical conductivity, making it ideal for electronic components, printed circuit boards, and electromagnetic shielding. It provides enhanced corrosion resistance and improved solderability, commonly applied in automotive parts, aerospace components, and decorative finishes. Unlike copper cladding, which is thicker and mainly used for structural purposes, copper plating offers a thin, uniform, and cost-effective coating for precision applications.

Cost Considerations: Cladding vs Plating

Copper cladding typically involves bonding a thin layer of copper to a base metal through heat and pressure, resulting in higher initial costs due to the complex manufacturing process, but offers enhanced durability and corrosion resistance. Copper plating applies a thinner copper layer using electrochemical deposition, which is generally more cost-effective for smaller applications but may require frequent maintenance or re-plating, increasing long-term expenses. Evaluating project size, durability needs, and maintenance frequency is crucial in determining whether copper cladding or plating presents a better cost-value proposition.

How to Choose Between Copper Cladding and Copper Plating

Choosing between copper cladding and copper plating depends on factors such as desired durability, cost, and application requirements. Copper cladding provides a thicker, more robust layer ideal for structural protection and long-term exposure, while copper plating offers a thinner, more precise coating suited for electronic components and decorative finishes. Evaluating environmental conditions and performance needs guides the optimal selection between these copper finishing techniques.

Copper Cladding vs Copper Plating Infographic

materialdif.com

materialdif.com