Rolled copper features a malleable texture achieved by passing heated copper through rollers, resulting in sheets or strips ideal for roofing and decorative applications. Drawn copper is produced by pulling heated copper through dies, creating wires or tubes with enhanced tensile strength and precision dimensions, making it suitable for electrical wiring and plumbing. Choosing between rolled and drawn copper depends on the intended use, with rolled copper offering flexibility and surface finish, while drawn copper provides durability and dimensional accuracy.

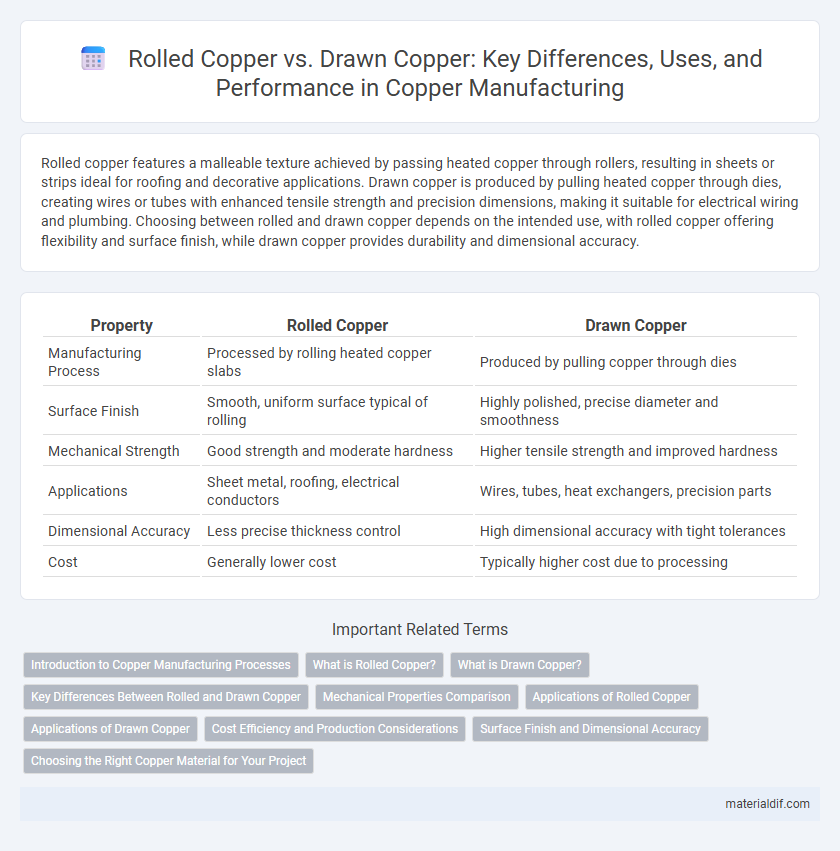

Table of Comparison

| Property | Rolled Copper | Drawn Copper |

|---|---|---|

| Manufacturing Process | Processed by rolling heated copper slabs | Produced by pulling copper through dies |

| Surface Finish | Smooth, uniform surface typical of rolling | Highly polished, precise diameter and smoothness |

| Mechanical Strength | Good strength and moderate hardness | Higher tensile strength and improved hardness |

| Applications | Sheet metal, roofing, electrical conductors | Wires, tubes, heat exchangers, precision parts |

| Dimensional Accuracy | Less precise thickness control | High dimensional accuracy with tight tolerances |

| Cost | Generally lower cost | Typically higher cost due to processing |

Introduction to Copper Manufacturing Processes

Rolled copper undergoes a process where heated copper slab is passed through rollers to achieve desired thickness and surface finish, optimizing its physical properties for structural applications. Drawn copper involves pulling the metal through dies to produce wire with precise diameter and enhanced tensile strength, commonly used in electrical wiring and electronics. Both methods control copper's microstructure and mechanical characteristics to meet specific industrial requirements.

What is Rolled Copper?

Rolled copper is a type of copper processed by passing copper slabs or billets through heavy rollers to achieve a uniform thickness and smooth surface, commonly used in electrical conductors and roofing materials. This shaping method enhances the metal's mechanical strength and conductivity while maintaining excellent ductility. Rolled copper exhibits improved texture and grain structure compared to drawn copper, making it suitable for applications requiring precise thickness and high surface quality.

What is Drawn Copper?

Drawn copper refers to copper that has been mechanically pulled through a die to create long, thin shapes such as wires or tubes with precise dimensions and improved strength. This process enhances the metal's tensile properties while maintaining its excellent electrical and thermal conductivity, making it ideal for electrical wiring and industrial applications. Compared to rolled copper, drawn copper offers superior uniformity and surface finish, crucial for high-performance electrical components.

Key Differences Between Rolled and Drawn Copper

Rolled copper undergoes a hot or cold rolling process that compresses the metal into thin sheets or strips, enhancing its surface smoothness and uniform thickness, ideal for applications requiring flat, flexible material such as roofing and cladding. Drawn copper is produced by pulling the metal through dies to form wires or rods, resulting in increased tensile strength and improved ductility, making it essential for electrical wiring and intricate mechanical parts. The primary difference lies in their manufacturing techniques and resulting physical properties, where rolled copper emphasizes flatness and surface finish, while drawn copper focuses on elongation and strength.

Mechanical Properties Comparison

Rolled copper exhibits higher tensile strength and better surface finish due to the compressive forces applied during the rolling process, enhancing its hardness and fatigue resistance. Drawn copper, formed by pulling the metal through dies, demonstrates improved ductility and elongation, making it ideal for applications requiring extensive bending or shaping. Mechanical properties such as yield strength and electrical conductivity may slightly vary depending on the degree of work hardening in each processing method.

Applications of Rolled Copper

Rolled copper's flat, uniform sheets and plates make it ideal for electrical components, roofing materials, and heat exchangers, where consistent thickness and surface finish are critical. Its superior malleability and high thermal conductivity enable efficient manufacturing of connectors, circuit boards, and decorative architectural elements. The material's strength and corrosion resistance also support its use in automotive radiators and industrial machinery parts.

Applications of Drawn Copper

Drawn copper is widely used in electrical wiring due to its superior tensile strength and flexibility, making it ideal for intricate cable configurations and high-stress environments. Its enhanced surface finish and dimensional accuracy support precision components in electronics and telecommunications. The metal's excellent conductivity combined with mechanical durability also suits applications in automotive wiring and industrial equipment.

Cost Efficiency and Production Considerations

Rolled copper offers cost efficiency through lower production expenses and faster processing times compared to drawn copper, which requires more complex machinery and longer manufacturing steps. The production process of rolled copper involves flattening slabs or billets, making it suitable for large-scale applications where uniform thickness and surface finish are essential. Drawn copper, produced by pulling the metal through dies, yields higher strength and precision but demands greater energy input and maintenance costs, impacting overall cost-effectiveness for volume production.

Surface Finish and Dimensional Accuracy

Rolled copper exhibits a smooth surface finish with excellent dimensional uniformity due to the controlled pressure applied during the rolling process, making it ideal for applications requiring consistent thickness and flatness. Drawn copper, produced by pulling through dies, offers superior dimensional accuracy and surface finish quality, often resulting in enhanced mechanical properties and a polished appearance suitable for precision components. Both methods significantly impact the final product's surface integrity and dimensional tolerances, with drawn copper typically favored for intricate shapes and tight specifications.

Choosing the Right Copper Material for Your Project

Rolled copper offers superior strength and a smoother surface finish, making it ideal for applications requiring durability and aesthetic appeal, such as roofing and decorative panels. Drawn copper, characterized by its enhanced ductility and precise dimensional control, is preferred for intricate electrical components and tubing where flexibility and conductivity are critical. Selecting between rolled and drawn copper depends on project demands for mechanical properties, surface finish, and formability to ensure optimal performance.

Rolled Copper vs Drawn Copper Infographic

materialdif.com

materialdif.com