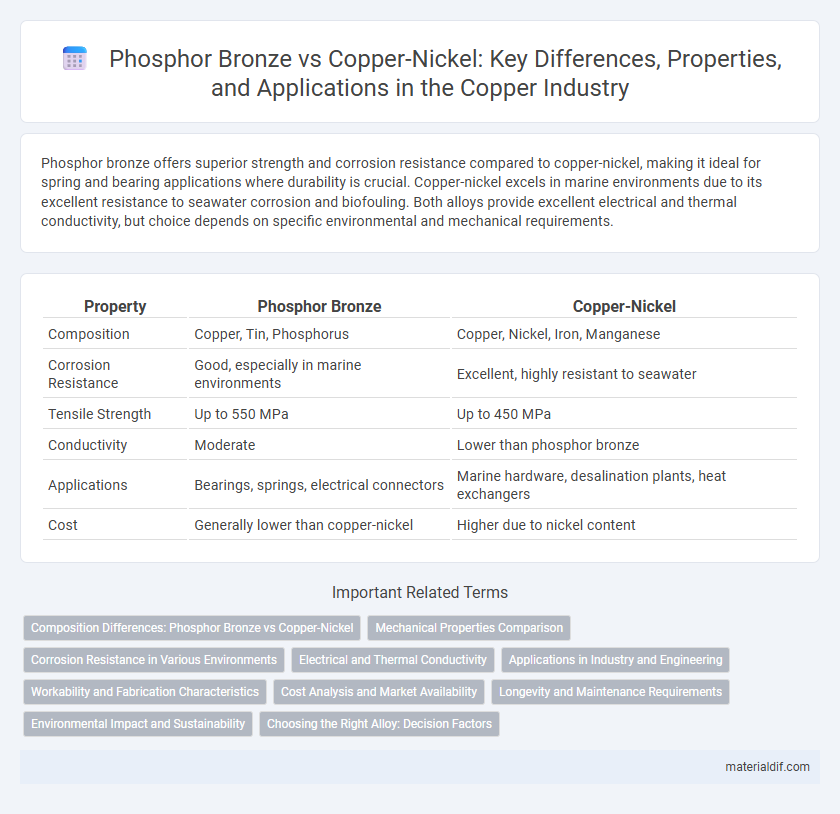

Phosphor bronze offers superior strength and corrosion resistance compared to copper-nickel, making it ideal for spring and bearing applications where durability is crucial. Copper-nickel excels in marine environments due to its excellent resistance to seawater corrosion and biofouling. Both alloys provide excellent electrical and thermal conductivity, but choice depends on specific environmental and mechanical requirements.

Table of Comparison

| Property | Phosphor Bronze | Copper-Nickel |

|---|---|---|

| Composition | Copper, Tin, Phosphorus | Copper, Nickel, Iron, Manganese |

| Corrosion Resistance | Good, especially in marine environments | Excellent, highly resistant to seawater |

| Tensile Strength | Up to 550 MPa | Up to 450 MPa |

| Conductivity | Moderate | Lower than phosphor bronze |

| Applications | Bearings, springs, electrical connectors | Marine hardware, desalination plants, heat exchangers |

| Cost | Generally lower than copper-nickel | Higher due to nickel content |

Composition Differences: Phosphor Bronze vs Copper-Nickel

Phosphor bronze consists primarily of copper with 0.5-11% tin and 0.01-0.35% phosphorus, which enhances corrosion resistance and strength. Copper-nickel alloys contain 60-90% copper and 10-40% nickel, offering superior resistance to seawater corrosion and biofouling. The substantial tin content in phosphor bronze contrasts with the prominent nickel presence in copper-nickel, resulting in differing mechanical properties and applications.

Mechanical Properties Comparison

Phosphor bronze exhibits superior tensile strength and hardness compared to copper-nickel, making it ideal for applications requiring high mechanical durability. Copper-nickel offers greater corrosion resistance and better fatigue strength, beneficial in marine environments and heat exchangers. Both alloys have excellent ductility, but phosphor bronze maintains performance under higher stress conditions.

Corrosion Resistance in Various Environments

Phosphor bronze exhibits superior corrosion resistance in marine environments due to its strong resistance to saltwater and biofouling. Copper-Nickel alloys provide excellent protection against seawater corrosion and erosion, often outperforming phosphor bronze in high-salinity and polluted waters. Both materials resist oxidation, but copper-nickel's enhanced resistance to microbial-induced corrosion makes it preferable for harsh industrial applications.

Electrical and Thermal Conductivity

Phosphor bronze exhibits lower electrical conductivity, typically around 15-25% IACS (International Annealed Copper Standard), compared to copper-nickel alloys that usually range between 20-40% IACS due to their higher nickel content. Thermal conductivity of phosphor bronze is approximately 60-110 W/m*K, which is significantly lower than copper-nickel's 30-60 W/m*K, reflecting its denser microstructure and alloy composition. These conductivity differences make phosphor bronze suitable for applications requiring moderate electrical and high corrosion resistance, while copper-nickel is preferred where better electrical performance and enhanced thermal stability are essential.

Applications in Industry and Engineering

Phosphor bronze is widely used in electrical connectors, springs, and marine hardware due to its excellent fatigue resistance, corrosion resistance, and high strength. Copper-nickel alloys excel in seawater applications, such as desalination plants, heat exchangers, and marine engineering, because of their superior resistance to biofouling and erosion. Both materials are essential in industrial and engineering sectors where durability and corrosion resistance are critical, but phosphor bronze is preferred for mechanical components while copper-nickel is ideal for harsh aquatic environments.

Workability and Fabrication Characteristics

Phosphor bronze offers superior workability with excellent spring qualities and high resistance to fatigue, making it ideal for precision components that require forming and bending. Copper-nickel alloys exhibit good corrosion resistance and moderate workability but are generally less ductile than phosphor bronze, impacting their performance in complex fabrication processes. The fabrication characteristics of phosphor bronze facilitate processes like stamping, machining, and welding with minimal cracking, while copper-nickel requires more careful thermal management during shaping to maintain integrity.

Cost Analysis and Market Availability

Phosphor bronze generally commands a higher price than copper-nickel due to its alloy composition and specialized applications, impacting overall cost efficiency in manufacturing. Copper-nickel offers greater market availability and a broad supply chain, making it more accessible for large-scale industrial use. Manufacturers often weigh the balance between phosphor bronze's superior mechanical properties and copper-nickel's cost-effectiveness and availability to determine the optimal material choice.

Longevity and Maintenance Requirements

Phosphor bronze offers superior longevity due to its enhanced corrosion resistance and fatigue strength, making it ideal for applications requiring durable components with minimal wear. Copper-nickel alloys exhibit moderate maintenance requirements as they resist marine corrosion and biofouling but may require periodic inspection in harsh environments. Maintenance costs for phosphor bronze are generally lower over time because its stable oxide layer reduces the need for frequent cleaning or replacement compared to copper-nickel alloys.

Environmental Impact and Sustainability

Phosphor bronze, composed primarily of copper, tin, and phosphorus, offers excellent corrosion resistance and durability, reducing the need for frequent replacements and minimizing waste over time, which contributes to sustainability. Copper-nickel alloys, containing copper and nickel, are highly resistant to biofouling in marine environments, leading to less chemical cleaning and maintenance, thereby lowering environmental contamination risks. Both materials support eco-friendly applications, but phosphor bronze's longer lifespan and recyclability provide a slightly better environmental impact profile compared to copper-nickel.

Choosing the Right Alloy: Decision Factors

Phosphor Bronze offers superior wear resistance and excellent fatigue strength, making it ideal for springs and bearings, while Copper-Nickel excels in corrosion resistance and marine applications due to its high tolerance to seawater and biofouling. Decision factors include environmental conditions, mechanical stress, and required electrical conductivity, with Phosphor Bronze favored in high-load, high-stress scenarios and Copper-Nickel preferred for harsh, saltwater exposure. Cost and machinability also play crucial roles, as Copper-Nickel typically has higher corrosion resistance but lower strength compared to Phosphor Bronze.

Phosphor Bronze vs Copper-Nickel Infographic

materialdif.com

materialdif.com