Copper mesh offers superior flexibility and breathability compared to copper sheets, making it ideal for applications requiring airflow and mold prevention. Copper sheets provide a solid, durable surface that excels in structural support and electrical conductivity where rigidity is crucial. Choosing between copper mesh and copper sheet depends on whether ventilation or sturdiness is the priority in your copper pet project.

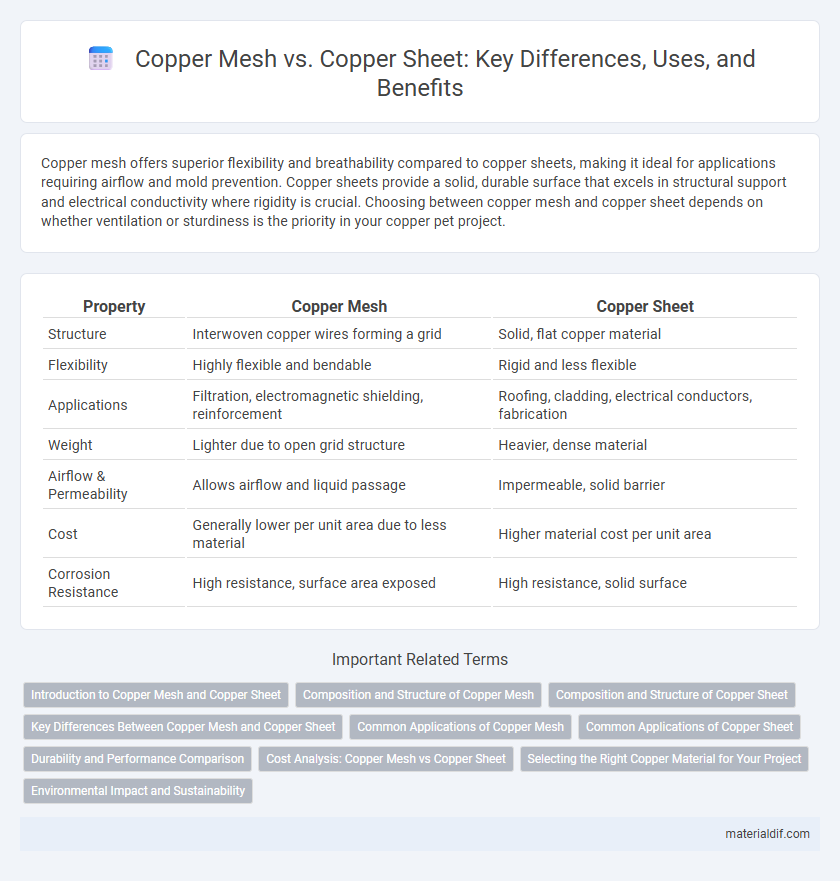

Table of Comparison

| Property | Copper Mesh | Copper Sheet |

|---|---|---|

| Structure | Interwoven copper wires forming a grid | Solid, flat copper material |

| Flexibility | Highly flexible and bendable | Rigid and less flexible |

| Applications | Filtration, electromagnetic shielding, reinforcement | Roofing, cladding, electrical conductors, fabrication |

| Weight | Lighter due to open grid structure | Heavier, dense material |

| Airflow & Permeability | Allows airflow and liquid passage | Impermeable, solid barrier |

| Cost | Generally lower per unit area due to less material | Higher material cost per unit area |

| Corrosion Resistance | High resistance, surface area exposed | High resistance, solid surface |

Introduction to Copper Mesh and Copper Sheet

Copper mesh consists of fine, woven copper wires creating a flexible, porous material ideal for electromagnetic interference (EMI) shielding and filtration. Copper sheets are solid, flat plates offering excellent thermal and electrical conductivity, widely used in electrical components and roofing. Both forms provide corrosion resistance and durability but differ in flexibility and airflow capabilities.

Composition and Structure of Copper Mesh

Copper mesh consists of fine strands of copper woven into a flexible, porous structure, enhancing its surface area and conductivity compared to solid copper sheets. Its composition typically involves high-purity copper with minimal alloying elements to maintain excellent electrical and thermal properties. This structural design enables superior electromagnetic shielding and efficient heat dissipation in applications where the rigidity of copper sheets is less desirable.

Composition and Structure of Copper Sheet

Copper sheets are composed of high-purity copper with a consistent grain structure that provides excellent electrical and thermal conductivity. Unlike copper mesh, which consists of woven or welded copper strands creating a permeable grid, copper sheets feature a solid, smooth surface ideal for applications requiring uniform conductivity and strength. The dense, homogeneous structure of copper sheets offers superior corrosion resistance and mechanical durability compared to the open, flexible design of copper mesh.

Key Differences Between Copper Mesh and Copper Sheet

Copper mesh features a woven grid structure that allows airflow and flexibility, making it ideal for applications like filtration, electromagnetic shielding, and insect screens. Copper sheets are solid, flat, and rigid, providing superior strength, corrosion resistance, and electrical conductivity for uses in roofing, circuitry, and decorative purposes. The primary difference lies in their physical form and application suitability: mesh offers permeability and flexibility, while sheets provide durability and continuous surface coverage.

Common Applications of Copper Mesh

Copper mesh is widely used in electromagnetic interference (EMI) shielding, filter screens, and grounding applications due to its flexible structure and excellent conductivity. It is preferred in pest control, especially for sealing gaps and preventing rodents or insects, whereas copper sheets are typically chosen for structural or decorative purposes. The porous nature of copper mesh also makes it ideal for filtration and catalytic converters in automotive and industrial processes.

Common Applications of Copper Sheet

Copper sheets are widely utilized in electrical wiring, roofing, and plumbing due to their excellent conductivity, corrosion resistance, and malleability. These sheets serve as a durable material for manufacturing heat exchangers, architectural cladding, and decorative elements in both industrial and residential settings. Copper sheet's versatility makes it essential for applications requiring both structural integrity and aesthetic appeal.

Durability and Performance Comparison

Copper mesh offers superior flexibility and increased surface area, making it ideal for applications requiring ventilation and electromagnetic interference shielding. Copper sheets provide enhanced structural durability and corrosion resistance, suitable for roofing and industrial fabrications demanding long-term mechanical strength. The choice between copper mesh and copper sheet depends on the specific durability requirements and performance goals of the project.

Cost Analysis: Copper Mesh vs Copper Sheet

Copper mesh typically costs more per square foot than copper sheet due to its intricate manufacturing process and lower material density. Copper sheet offers a more economical choice for large surface area applications, providing higher material volume at a lower price point. When evaluating cost-effectiveness, consider labor and installation expenses, as mesh requires more careful handling and fastening compared to the easily shaped and installed copper sheets.

Selecting the Right Copper Material for Your Project

Copper mesh offers superior flexibility and enhanced airflow, making it ideal for applications like electromagnetic interference (EMI) shielding and filtration systems. Copper sheets provide durability and structural support, suitable for roofing, electrical components, and artistic metalwork requiring a solid, flat surface. Selecting the right copper material depends on project needs for conductivity, strength, and adaptability, with copper mesh excelling in ventilation and copper sheets favored for rigidity and corrosion resistance.

Environmental Impact and Sustainability

Copper mesh offers enhanced sustainability due to its greater surface area, promoting better recycling efficiency and reducing waste. Copper sheets require more raw material extraction, resulting in higher environmental impact and carbon emissions during production. Utilizing copper mesh supports eco-friendly applications by minimizing resource consumption and enabling easier material recovery.

Copper Mesh vs Copper Sheet Infographic

materialdif.com

materialdif.com