Copper exhibits higher electrical conductivity and corrosion resistance compared to zinc, making it ideal for electrical wiring and plumbing applications. Zinc, while less conductive, offers superior galvanizing properties to protect steel from rust and is more cost-effective for industrial coatings. The distinct physical and chemical characteristics of copper and zinc determine their complementary roles in various manufacturing and construction processes.

Table of Comparison

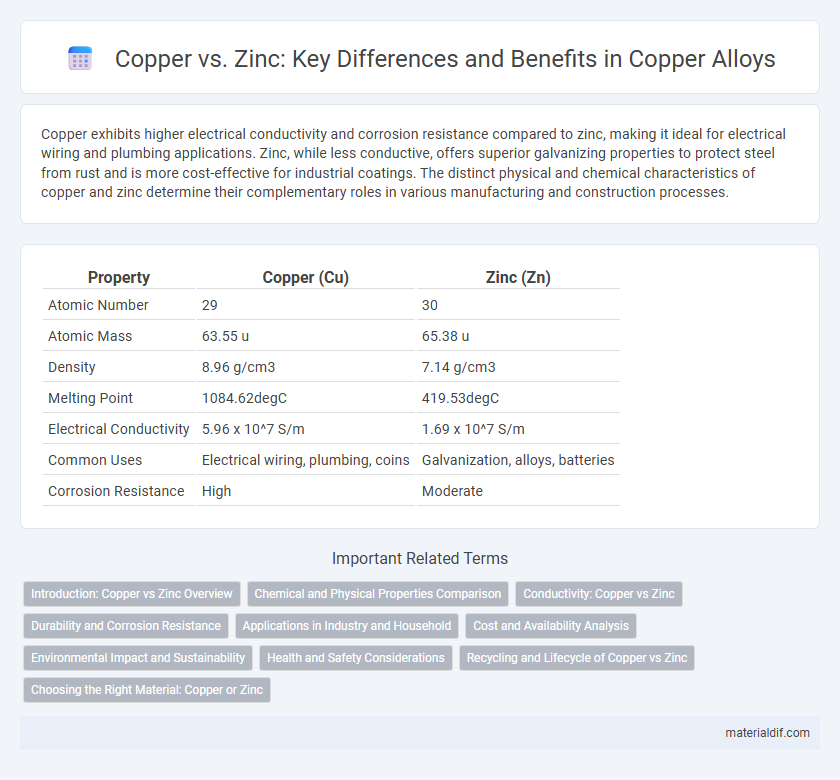

| Property | Copper (Cu) | Zinc (Zn) |

|---|---|---|

| Atomic Number | 29 | 30 |

| Atomic Mass | 63.55 u | 65.38 u |

| Density | 8.96 g/cm3 | 7.14 g/cm3 |

| Melting Point | 1084.62degC | 419.53degC |

| Electrical Conductivity | 5.96 x 10^7 S/m | 1.69 x 10^7 S/m |

| Common Uses | Electrical wiring, plumbing, coins | Galvanization, alloys, batteries |

| Corrosion Resistance | High | Moderate |

Introduction: Copper vs Zinc Overview

Copper and zinc are essential transition metals with distinct properties and applications, where copper boasts superior electrical conductivity and corrosion resistance, while zinc is primarily valued for its galvanizing capacity and alloying with other metals. Copper's atomic number 29 and high thermal conductivity make it indispensable in electrical wiring and electronics, whereas zinc, with atomic number 30, plays a crucial role in protecting steel from rust and enhancing die-casting alloys. Both elements are vital in industrial processes but serve different functions based on their chemical behavior and physical characteristics.

Chemical and Physical Properties Comparison

Copper exhibits superior electrical conductivity and malleability compared to zinc, making it essential in electrical wiring and plumbing. Chemically, copper has a higher resistance to corrosion due to its ability to form a protective oxide layer, whereas zinc readily oxidizes and is primarily used for galvanizing steel to prevent rust. Copper's melting point is 1,084degC, significantly higher than zinc's 419.5degC, influencing their applications in high-temperature environments.

Conductivity: Copper vs Zinc

Copper exhibits significantly higher electrical conductivity compared to zinc, with copper's conductivity rating at approximately 5.96 x 10^7 S/m, while zinc measures around 1.69 x 10^7 S/m. This substantial difference makes copper the preferred choice for electrical wiring and components where efficient current flow is critical. Zinc, having lower conductivity, is primarily used for galvanizing and as an alloying element rather than in applications requiring superior electrical performance.

Durability and Corrosion Resistance

Copper exhibits superior corrosion resistance compared to zinc due to its stable oxide layer that protects against environmental damage, making it highly durable in varied conditions. Zinc, while less corrosion-resistant, offers moderate durability primarily in protective coatings such as galvanization but tends to degrade faster in harsh environments. The inherent chemical properties of copper contribute to its longevity in plumbing and electrical applications, outperforming zinc where sustained exposure to moisture and air occurs.

Applications in Industry and Household

Copper is extensively used in electrical wiring, plumbing, and roofing due to its excellent conductivity and corrosion resistance, making it indispensable in both industrial and household applications. Zinc primarily serves as a protective coating for steel in galvanization, enhancing durability in construction, while also being a key component in batteries and die-casting alloys. Industrial sectors favor copper for its thermal and electrical efficiency, whereas zinc is preferred for its anti-corrosive properties and affordability in everyday household tools and fixtures.

Cost and Availability Analysis

Copper generally commands a higher market price than zinc due to its broader industrial applications and greater demand in electrical wiring and electronics. Zinc tends to be more abundant and cost-effective, making it a preferred choice for galvanization and alloy production where cost reduction is critical. Availability fluctuations in copper are often influenced by mining constraints and geopolitical factors, whereas zinc supply is steadier owing to more widespread deposits and stable production levels.

Environmental Impact and Sustainability

Copper mining and production generate fewer greenhouse gas emissions compared to zinc, making copper a more environmentally sustainable metal in industrial applications. Copper's high recyclability, with about 90% of the metal being recycled globally, significantly reduces its environmental footprint relative to zinc, which has lower recycling rates. Additionally, copper's longer lifespan in electrical and construction uses minimizes resource depletion and supports sustainable material management.

Health and Safety Considerations

Copper and zinc are essential trace minerals with distinct health and safety profiles; copper exposure in high amounts can lead to toxicity symptoms like nausea and liver damage, whereas zinc overdose may cause gastrointestinal distress and interfere with copper absorption. Occupational exposure limits set by organizations such as OSHA indicate that copper dust and fumes have a permissible exposure limit of 1 mg/m3, while zinc oxide fumes are capped at 5 mg/m3 to prevent respiratory issues. Proper handling, adequate ventilation, and use of personal protective equipment are critical measures to minimize risks associated with both metals in industrial and consumer applications.

Recycling and Lifecycle of Copper vs Zinc

Copper exhibits a higher recycling rate compared to zinc, with approximately 80% of copper in use today derived from recycled sources, reducing the need for energy-intensive mining. The lifecycle of copper involves multiple remelting cycles that maintain its material properties, whereas zinc recycling faces challenges due to contamination and lower economic incentives. Efficient copper recycling significantly lowers environmental impact and conserves natural resources, positioning copper as a more sustainable metal than zinc throughout its lifecycle.

Choosing the Right Material: Copper or Zinc

Choosing between copper and zinc depends on the intended application, as copper offers superior electrical conductivity and corrosion resistance, making it ideal for electrical wiring and plumbing. Zinc excels in galvanization, providing an effective protective coating for steel and iron to prevent rust. Understanding these material properties ensures the right metal is selected for durability and performance in construction, manufacturing, or electrical projects.

Copper vs Zinc Infographic

materialdif.com

materialdif.com