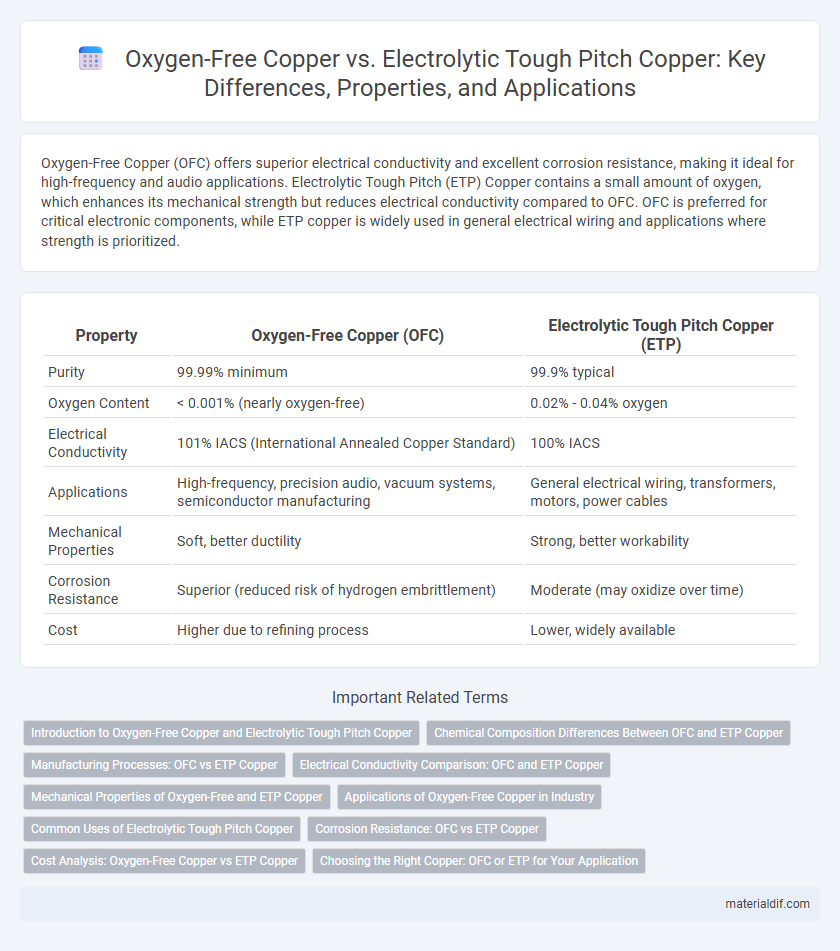

Oxygen-Free Copper (OFC) offers superior electrical conductivity and excellent corrosion resistance, making it ideal for high-frequency and audio applications. Electrolytic Tough Pitch (ETP) Copper contains a small amount of oxygen, which enhances its mechanical strength but reduces electrical conductivity compared to OFC. OFC is preferred for critical electronic components, while ETP copper is widely used in general electrical wiring and applications where strength is prioritized.

Table of Comparison

| Property | Oxygen-Free Copper (OFC) | Electrolytic Tough Pitch Copper (ETP) |

|---|---|---|

| Purity | 99.99% minimum | 99.9% typical |

| Oxygen Content | < 0.001% (nearly oxygen-free) | 0.02% - 0.04% oxygen |

| Electrical Conductivity | 101% IACS (International Annealed Copper Standard) | 100% IACS |

| Applications | High-frequency, precision audio, vacuum systems, semiconductor manufacturing | General electrical wiring, transformers, motors, power cables |

| Mechanical Properties | Soft, better ductility | Strong, better workability |

| Corrosion Resistance | Superior (reduced risk of hydrogen embrittlement) | Moderate (may oxidize over time) |

| Cost | Higher due to refining process | Lower, widely available |

Introduction to Oxygen-Free Copper and Electrolytic Tough Pitch Copper

Oxygen-Free Copper (OFC) is a high-purity copper grade with oxygen content less than 0.001%, offering superior electrical conductivity and enhanced corrosion resistance ideal for high-performance electrical applications. Electrolytic Tough Pitch (ETP) Copper contains approximately 0.02% to 0.04% oxygen, which improves its mechanical properties and conductivity, making it a common choice for general electrical wiring and industrial components. OFC is preferred where minimal oxygen is crucial to prevent embrittlement, while ETP copper balances cost-efficiency with reliable conductivity for broad use.

Chemical Composition Differences Between OFC and ETP Copper

Oxygen-Free Copper (OFC) contains a minimum copper purity of 99.95% with oxygen content below 0.001%, ensuring superior electrical conductivity and minimal oxide inclusions. Electrolytic Tough Pitch (ETP) Copper typically includes 99.9% copper with oxygen content around 0.02-0.04%, which can form copper oxides impacting conductivity. The chemical composition difference primarily lies in the oxygen level, affecting both electrical performance and suitability for applications requiring high conductivity.

Manufacturing Processes: OFC vs ETP Copper

Oxygen-Free Copper (OFC) is produced through a refining process involving electrolysis or vacuum melting to reduce oxygen content to below 0.001%, resulting in higher purity and enhanced conductivity. Electrolytic Tough Pitch (ETP) Copper undergoes electrorefining where oxygen content is deliberately maintained around 0.02% to 0.05%, balancing cost and conductivity for general electrical applications. The manufacturing difference impacts electrical performance, with OFC offering superior conductivity and corrosion resistance due to minimal oxygen impurities compared to ETP copper.

Electrical Conductivity Comparison: OFC and ETP Copper

Oxygen-Free Copper (OFC) offers superior electrical conductivity, typically around 101% IACS (International Annealed Copper Standard), due to its high purity and minimal oxygen content, which reduces the risk of oxidation and improves electron flow. Electrolytic Tough Pitch (ETP) Copper, while slightly less conductive at 100% IACS, contains small amounts of oxygen that can form copper oxides, slightly hindering conductivity under certain conditions. OFC is preferred in high-performance electrical applications where maximum conductivity and minimal signal loss are critical, whereas ETP copper remains widely used in general electrical wiring and industrial applications due to its good conductivity and lower cost.

Mechanical Properties of Oxygen-Free and ETP Copper

Oxygen-Free Copper (OFC) exhibits superior tensile strength and ductility compared to Electrolytic Tough Pitch (ETP) Copper due to its minimal oxygen content, which reduces the risk of embrittlement and enhances mechanical performance. ETP Copper, containing approximately 0.02-0.04% oxygen, has slightly lower mechanical strength but improved electrical conductivity, making it suitable for electrical applications. The microstructure of OFC results in enhanced resistance to stress corrosion cracking and better cold formability compared to ETP Copper.

Applications of Oxygen-Free Copper in Industry

Oxygen-Free Copper (OFC) is highly valued in industries requiring superior electrical conductivity and corrosion resistance, such as electronics manufacturing, aerospace, and power transmission. Its low oxygen content enhances thermal conductivity, making it ideal for high-performance electrical connectors, superconductors, and vacuum tubes. OFC is also extensively used in audio equipment and semiconductor applications where signal purity and reliability are critical.

Common Uses of Electrolytic Tough Pitch Copper

Electrolytic Tough Pitch (ETP) copper is widely used in electrical wiring, busbars, and connectors due to its excellent conductivity and cost-effectiveness. Its oxygen content provides superior thermal conductivity and ease of soldering, making it ideal for power distribution and electronic components. ETP copper also finds common application in transformers, motors, and industrial machinery where reliable electrical performance is essential.

Corrosion Resistance: OFC vs ETP Copper

Oxygen-Free Copper (OFC) offers superior corrosion resistance compared to Electrolytic Tough Pitch (ETP) copper due to its minimal oxygen content, which reduces the risk of internal oxidation and enhances long-term durability in harsh environments. ETP copper contains a small amount of oxygen, typically around 0.02%-0.04%, which can lead to copper oxide formation and increased susceptibility to corrosion in certain applications. This makes OFC the preferred choice in high-performance electrical and industrial systems where corrosion resistance is critical.

Cost Analysis: Oxygen-Free Copper vs ETP Copper

Oxygen-Free Copper (OFC) generally incurs higher production costs due to its refined manufacturing process that eliminates oxygen, resulting in superior electrical conductivity and corrosion resistance compared to Electrolytic Tough Pitch (ETP) Copper. ETP Copper, while more economical, contains trace oxygen that enhances its machinability but can compromise performance in high-purity applications. The cost analysis favors OFC for specialized uses requiring purity and reliability, whereas ETP Copper remains cost-effective for standard electrical components and bulk applications.

Choosing the Right Copper: OFC or ETP for Your Application

Oxygen-Free Copper (OFC) offers superior electrical conductivity and corrosion resistance, making it ideal for high-performance electronics and audio applications where purity and durability are critical. Electrolytic Tough Pitch (ETP) Copper, with its higher oxygen content, provides excellent thermal and electrical conductivity at a lower cost, suitable for general electrical wiring and industrial uses. Selecting between OFC and ETP depends on the application's sensitivity to conductivity, durability requirements, and budget constraints.

Oxygen-Free Copper vs Electrolytic Tough Pitch Copper Infographic

materialdif.com

materialdif.com