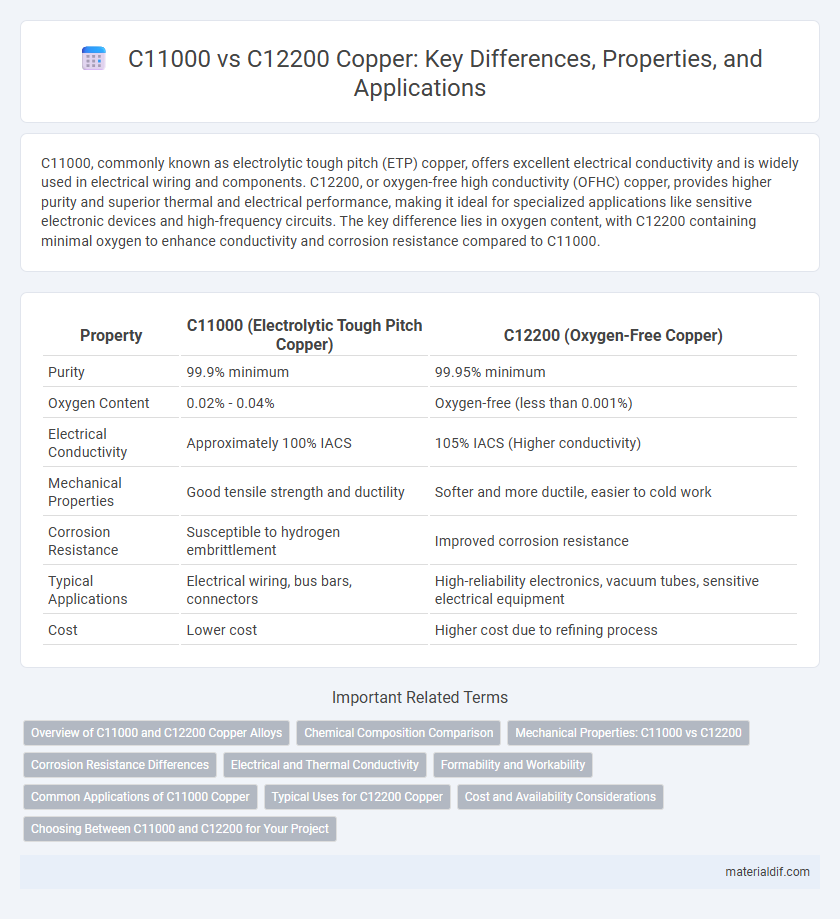

C11000, commonly known as electrolytic tough pitch (ETP) copper, offers excellent electrical conductivity and is widely used in electrical wiring and components. C12200, or oxygen-free high conductivity (OFHC) copper, provides higher purity and superior thermal and electrical performance, making it ideal for specialized applications like sensitive electronic devices and high-frequency circuits. The key difference lies in oxygen content, with C12200 containing minimal oxygen to enhance conductivity and corrosion resistance compared to C11000.

Table of Comparison

| Property | C11000 (Electrolytic Tough Pitch Copper) | C12200 (Oxygen-Free Copper) |

|---|---|---|

| Purity | 99.9% minimum | 99.95% minimum |

| Oxygen Content | 0.02% - 0.04% | Oxygen-free (less than 0.001%) |

| Electrical Conductivity | Approximately 100% IACS | 105% IACS (Higher conductivity) |

| Mechanical Properties | Good tensile strength and ductility | Softer and more ductile, easier to cold work |

| Corrosion Resistance | Susceptible to hydrogen embrittlement | Improved corrosion resistance |

| Typical Applications | Electrical wiring, bus bars, connectors | High-reliability electronics, vacuum tubes, sensitive electrical equipment |

| Cost | Lower cost | Higher cost due to refining process |

Overview of C11000 and C12200 Copper Alloys

C11000 copper, also known as Electrolytic Tough Pitch (ETP) copper, features high electrical conductivity of approximately 101% IACS and is widely used for electrical wiring and components due to its excellent thermal and electrical properties. C12200 copper, commonly referred to as Oxygen-Free Electronic (OFE) copper, offers superior purity at 99.99% copper content, resulting in even higher conductivity and improved resistance to hydrogen embrittlement, making it ideal for high-performance electrical and electronic applications. Both alloys demonstrate excellent corrosion resistance and workability, with C12200 preferred for precision components where minimizing impurities is critical.

Chemical Composition Comparison

C11000 copper primarily consists of 99.90% pure copper with minimal oxygen content, ensuring excellent electrical conductivity. In contrast, C12200 contains slightly higher oxygen levels due to its deoxidized composition, with copper purity around 99.90% but enhanced mechanical strength. The difference in oxygen content between C11000 (electrolytic tough pitch copper) and C12200 (oxygen-free copper) significantly affects their chemical properties and performance in specific applications.

Mechanical Properties: C11000 vs C12200

C11000 copper, commonly known as Electrolytic Tough Pitch (ETP), exhibits higher electrical conductivity around 100% IACS but possesses lower tensile strength approximately 210 MPa compared to C12200. C12200 copper, or Oxygen-Free Electronic (OFE) copper, features enhanced mechanical properties with tensile strength reaching up to 320 MPa and improved ductility due to its oxygen-free composition. These mechanical distinctions make C12200 preferable for high-strength applications while C11000 remains ideal for electrical conductivity-focused uses.

Corrosion Resistance Differences

C11000 copper, also known as Electrolytic Tough Pitch (ETP) copper, has excellent electrical conductivity but is more susceptible to corrosion in certain environments due to its higher oxygen content. C12200 copper, an Oxygen-Free Electronic (OFE) copper, offers superior corrosion resistance because of its minimal oxygen level, making it more suitable for applications exposed to harsh or corrosive conditions. The enhanced corrosion resistance of C12200 extends the longevity and performance of components in marine, chemical processing, and high-reliability electronic industries.

Electrical and Thermal Conductivity

C11000 copper, also known as Electrolytic Tough Pitch (ETP) copper, offers exceptional electrical conductivity of approximately 101% IACS (International Annealed Copper Standard) and thermal conductivity around 386 W/m*K, making it ideal for electrical applications requiring high efficiency. C12200 copper, or Oxygen-Free Electronic (OFE) copper, provides slightly lower electrical conductivity near 100% IACS but superior thermal conductivity due to its ultra-high purity and minimal oxygen content, enhancing performance in sensitive electronic components. Both grades maintain excellent conductivity, yet C12200 excels in thermal management for precision electronics, while C11000 is preferred for general electrical wiring due to cost-effectiveness and consistent conductivity.

Formability and Workability

C11000 copper, also known as Electrolytic Tough Pitch (ETP) copper, offers excellent formability with high electrical conductivity, making it ideal for intricate shapes and detailed fabrication processes. C12200 copper (phosphorus-deoxidized copper) provides superior workability due to its enhanced resistance to embrittlement and improved ductility, allowing for repeated forming operations without cracking. Both grades maintain strong mechanical properties, but C12200 is preferred for complex forming tasks where enhanced durability and resistance to stress are crucial.

Common Applications of C11000 Copper

C11000 copper, also known as Electrolytic Tough Pitch (ETP) copper, is widely used in electrical wiring, bus bars, and heat exchangers due to its excellent electrical conductivity and corrosion resistance. Its common applications include electrical connectors, transformers, and motors where high conductivity is essential. C12200, while similar, is primarily chosen for applications requiring higher purity and slightly better electrical performance, but C11000 remains the standard for general electrical and mechanical uses.

Typical Uses for C12200 Copper

C12200 copper, also known as electrolytic tough pitch (ETP) copper, is widely used in electrical applications requiring high conductivity and excellent ductility, such as busbars, electrical wiring, and terminals. Its superior purity and oxygen content make it ideal for electronic components and vacuum tubes, where reliable electrical performance is critical. This grade is preferred over C11000 for precision electrical connectors and heavy-duty electrical conductors due to its enhanced mechanical properties and thermal conductivity.

Cost and Availability Considerations

C11000 copper, known for its high purity and excellent electrical conductivity, is generally more expensive due to its stringent manufacturing standards and widespread industrial demand. C12200 copper includes higher oxygen content, making it more cost-effective but with slightly lower conductivity, often preferred for applications where budget constraints outweigh the need for maximum performance. Availability of C11000 can be limited in bulk due to its high demand in electrical components, whereas C12200 is more readily available and commonly used in plumbing and general-purpose applications.

Choosing Between C11000 and C12200 for Your Project

C11000 copper, known for its high electrical conductivity of around 101% IACS, is ideal for electrical components requiring excellent conductivity and corrosion resistance. C12200 copper offers enhanced mechanical strength and improved formability due to its special alloying elements, making it suitable for applications involving complex shaping or higher mechanical stress. Selecting between C11000 and C12200 depends on balancing the need for maximum conductivity with mechanical durability demands in your project.

C11000 vs C12200 Infographic

materialdif.com

materialdif.com