Copper plates offer a flat, broad surface ideal for electrical and thermal applications requiring uniform conductivity, while copper rods provide cylindrical shapes best suited for structural supports and machining purposes. Plates are easier to cut and shape for large, flat components, whereas rods can be drawn into wires and used in hardware or fasteners. Choosing between copper plate and rod depends on the specific mechanical strength, conductivity, and fabrication needs of the project.

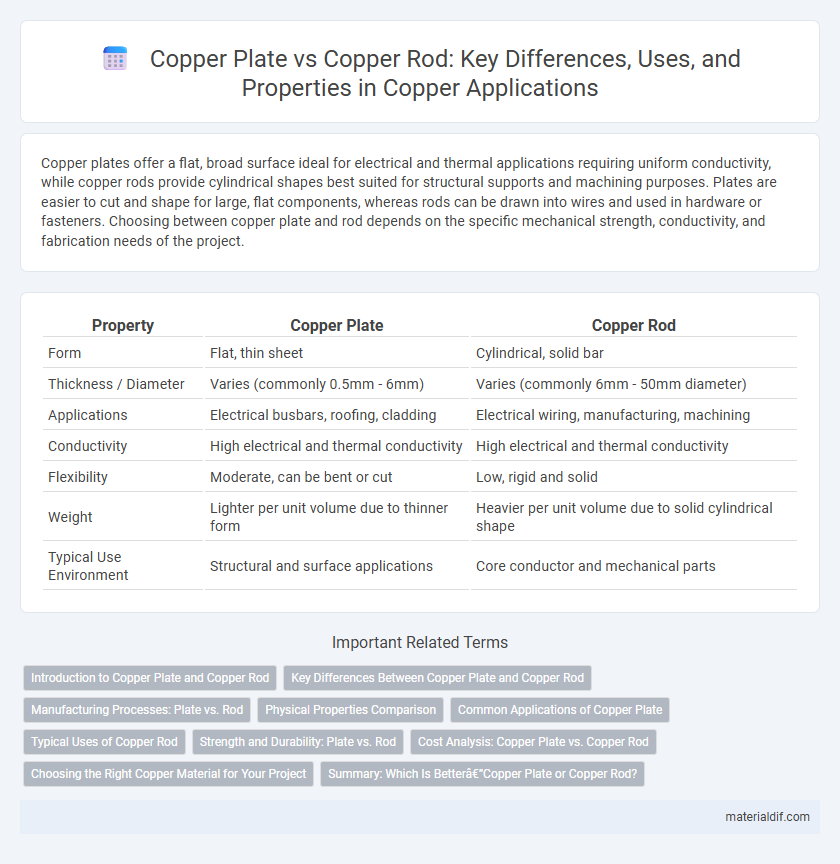

Table of Comparison

| Property | Copper Plate | Copper Rod |

|---|---|---|

| Form | Flat, thin sheet | Cylindrical, solid bar |

| Thickness / Diameter | Varies (commonly 0.5mm - 6mm) | Varies (commonly 6mm - 50mm diameter) |

| Applications | Electrical busbars, roofing, cladding | Electrical wiring, manufacturing, machining |

| Conductivity | High electrical and thermal conductivity | High electrical and thermal conductivity |

| Flexibility | Moderate, can be bent or cut | Low, rigid and solid |

| Weight | Lighter per unit volume due to thinner form | Heavier per unit volume due to solid cylindrical shape |

| Typical Use Environment | Structural and surface applications | Core conductor and mechanical parts |

Introduction to Copper Plate and Copper Rod

Copper plates offer a flat, durable surface ideal for electrical grounding, industrial fabrication, and architectural applications, characterized by excellent thermal and electrical conductivity. Copper rods, formed as long cylindrical bars, are widely utilized in manufacturing processes, including wire drawing, machining, and construction reinforcement. Both forms showcase copper's inherent corrosion resistance and malleability, meeting diverse industrial demands.

Key Differences Between Copper Plate and Copper Rod

Copper plates are flat, thin sheets primarily used in electrical grounding, heat exchangers, and architectural applications, offering extensive surface area and easy fabrication. Copper rods are solid cylindrical bars valued for their high mechanical strength and conductivity, commonly utilized in electrical wiring, construction, and machining. The key difference lies in their shape and application: plates provide broad, flat coverage while rods deliver structural integrity and are suited for bending or machining into specific components.

Manufacturing Processes: Plate vs. Rod

Copper plates are manufactured through continuous casting followed by hot and cold rolling processes, which refine the metal's grain structure for enhanced strength and surface finish. Copper rods are typically produced by extrusion or drawing processes, allowing precise control over diameter and mechanical properties suited for electrical and construction applications. Each process influences the final product's microstructure, resulting in plates with flat, broad surfaces and rods with high tensile strength and flexibility.

Physical Properties Comparison

Copper plates exhibit superior flatness and surface smoothness compared to copper rods, making them ideal for applications requiring uniform thickness and surface area. Copper rods possess higher tensile strength and better machinability due to their solid cylindrical form, which supports structural and mechanical uses. Both forms offer excellent electrical conductivity and corrosion resistance, but their distinct physical shapes influence their specific utility in industrial applications.

Common Applications of Copper Plate

Copper plates are widely used in electrical engineering for manufacturing connectors, busbars, and electrical enclosures due to their excellent conductivity and corrosion resistance. In construction, copper plates serve as roofing materials and flashing around windows and chimneys because of their durability and weather resistance. Additionally, copper plates are essential in industrial applications such as heat exchangers and decorative art pieces, where their malleability and aesthetic appeal are valued.

Typical Uses of Copper Rod

Copper rods are commonly used in electrical applications such as wiring, busbars, and grounding systems due to their excellent conductivity and flexibility. They are also utilized in manufacturing fasteners, springs, and automotive components where strength and corrosion resistance are essential. Unlike copper plates, which are typically employed for structural or shielding purposes, copper rods offer versatility for machining and forming in industrial processes.

Strength and Durability: Plate vs. Rod

Copper plates generally offer greater strength and durability due to their flat, broad surface that distributes stress more evenly under load, making them ideal for structural applications requiring resistance to bending and impact. Copper rods, while strong, are more susceptible to deformation under lateral forces because their cylindrical shape concentrates stress along a smaller cross-sectional area. The choice between copper plate and rod depends on the specific mechanical demands, where plates excel in withstanding shear and compressive forces, and rods perform well under tensile loads.

Cost Analysis: Copper Plate vs. Copper Rod

Copper plates generally cost more per kilogram than copper rods due to their flat, processed form requiring additional manufacturing steps. Bulk purchasing of copper rods often results in a lower unit price, making them more cost-effective for applications needing long, continuous lengths of copper material. However, the total cost analysis depends on specific project requirements, including material thickness, form factor, and machining expenses.

Choosing the Right Copper Material for Your Project

Copper plates offer excellent surface conductivity and are ideal for applications requiring flat, sturdy materials such as grounding busbars and electrical chassis, while copper rods provide superior tensile strength and are preferred in mechanical applications like fasteners and structural supports. Selecting between copper plate and copper rod depends on the project's electrical, mechanical, and thermal requirements, as copper plates excel in conductivity and heat dissipation, whereas copper rods deliver robust physical durability and versatility. Understanding the specific conductivity rating, tensile strength, dimensional stability, and fabrication needs ensures optimal performance and cost-efficiency in electrical, industrial, or construction projects.

Summary: Which Is Better—Copper Plate or Copper Rod?

Copper plates offer superior surface area and corrosion resistance, making them ideal for applications requiring efficient heat dissipation and durability. Copper rods provide enhanced tensile strength and flexibility, suitable for electrical wiring and structural components. The choice depends on the specific use case, with plates favored for thermal and protective purposes, while rods excel in mechanical and conductive roles.

Copper Plate vs Copper Rod Infographic

materialdif.com

materialdif.com