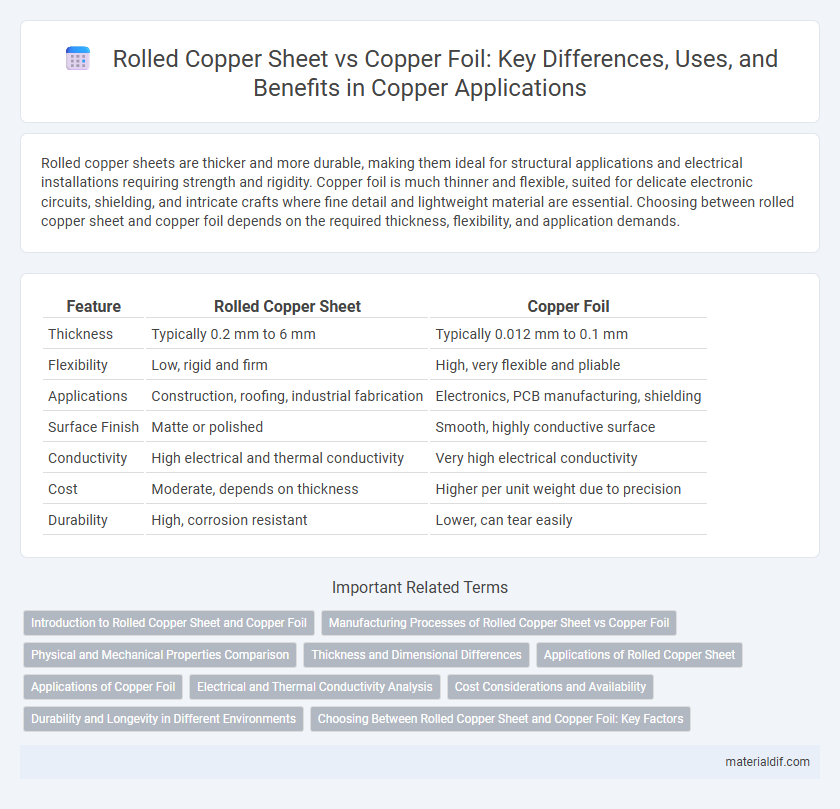

Rolled copper sheets are thicker and more durable, making them ideal for structural applications and electrical installations requiring strength and rigidity. Copper foil is much thinner and flexible, suited for delicate electronic circuits, shielding, and intricate crafts where fine detail and lightweight material are essential. Choosing between rolled copper sheet and copper foil depends on the required thickness, flexibility, and application demands.

Table of Comparison

| Feature | Rolled Copper Sheet | Copper Foil |

|---|---|---|

| Thickness | Typically 0.2 mm to 6 mm | Typically 0.012 mm to 0.1 mm |

| Flexibility | Low, rigid and firm | High, very flexible and pliable |

| Applications | Construction, roofing, industrial fabrication | Electronics, PCB manufacturing, shielding |

| Surface Finish | Matte or polished | Smooth, highly conductive surface |

| Conductivity | High electrical and thermal conductivity | Very high electrical conductivity |

| Cost | Moderate, depends on thickness | Higher per unit weight due to precision |

| Durability | High, corrosion resistant | Lower, can tear easily |

Introduction to Rolled Copper Sheet and Copper Foil

Rolled copper sheets are produced by passing copper slabs through heavy rollers to achieve a uniform thickness, making them ideal for structural applications and electrical components requiring durability. Copper foil, characterized by its ultra-thin and flexible nature, is manufactured through a different process involving casting or electro-deposition, enabling usage in fine electronics, shielding, and flexible circuits. Both forms offer excellent electrical conductivity and corrosion resistance but differ significantly in thickness, flexibility, and typical industrial applications.

Manufacturing Processes of Rolled Copper Sheet vs Copper Foil

Rolled copper sheets are produced through a hot rolling process followed by cold rolling, which reduces the metal's thickness while enhancing mechanical strength and surface finish. Copper foil is manufactured using an electrolysis process, where copper ions are deposited onto a cathode, resulting in ultra-thin, high-purity sheets essential for electronic applications. The rolling method balances thickness uniformity and durability, whereas electroplating provides exceptional thinness and conductivity.

Physical and Mechanical Properties Comparison

Rolled copper sheet exhibits higher thickness and superior mechanical strength compared to copper foil, making it ideal for structural applications requiring durability. Copper foil, characterized by its ultra-thin profile and enhanced flexibility, is preferred in electronic circuits and shielding where precise conductivity and easy conformance are essential. Both materials share excellent thermal and electrical conductivity, but their differences in tensile strength, ductility, and surface finish define specific industrial uses.

Thickness and Dimensional Differences

Rolled copper sheets typically have a thickness ranging from 0.2 mm to 6 mm, providing structural rigidity for industrial applications, while copper foils are much thinner, usually between 0.005 mm and 0.1 mm, enabling flexibility and fine detail work. Dimensional differences are critical: copper sheets maintain flatness and strength over broader areas, whereas copper foils can be easily sliced into ultra-thin layers for electronics and decorative uses. The selection between rolled copper sheet and copper foil depends on precise material thickness and desired mechanical properties.

Applications of Rolled Copper Sheet

Rolled copper sheets are widely used in electrical applications due to their excellent conductivity and durability, making them ideal for electrical busbars, transformers, and EMI shielding components. Their superior thickness and mechanical strength enable their use in roofing, cladding, and architectural design, where weather resistance and aesthetic appeal are crucial. Industrial uses include heat exchangers and fabrication of copper cookware, leveraging rolled sheets' thermal conductivity and formability.

Applications of Copper Foil

Copper foil is extensively used in the electronics industry for manufacturing printed circuit boards (PCBs) due to its excellent conductivity and flexibility. It also plays a critical role in battery technology, especially in lithium-ion batteries where it acts as a current collector. These applications leverage copper foil's thinness and uniformity, contrasting with rolled copper sheets which are preferred for structural and architectural uses.

Electrical and Thermal Conductivity Analysis

Rolled copper sheets exhibit superior electrical and thermal conductivity due to their greater thickness and structural integrity, making them ideal for high-current applications and efficient heat dissipation. Copper foil, while thinner and more flexible, offers excellent conductivity but with higher resistance and reduced heat transfer compared to rolled sheets, limiting its use in heavy-duty electrical components. Both materials maintain copper's inherent conductivity benefits, but the choice depends on the balance between mechanical flexibility and maximum conductive performance.

Cost Considerations and Availability

Rolled copper sheet typically offers a balance between cost and thickness, making it more affordable for larger-scale industrial applications, while copper foil tends to be pricier due to its ultra-thin gauge and specialized production process. Availability of rolled copper sheets is generally higher with larger distributors and metal suppliers due to widespread demand in construction and manufacturing. Copper foil, often sourced from niche suppliers, may experience limited stock and longer lead times because it caters to electronics, arts, and precision industries requiring thin, flexible material.

Durability and Longevity in Different Environments

Rolled copper sheets exhibit superior durability and resistance to wear, making them ideal for construction and industrial applications exposed to harsh environmental conditions such as moisture and temperature fluctuations. Copper foil, while thinner and more flexible, tends to oxidize faster and may degrade under prolonged exposure to corrosive environments, reducing its longevity. Both materials offer excellent corrosion resistance inherent to copper, but rolled sheets provide enhanced structural integrity for long-term performance in demanding settings.

Choosing Between Rolled Copper Sheet and Copper Foil: Key Factors

Choosing between rolled copper sheet and copper foil depends on thickness requirements, as rolled sheets typically range from 0.2 mm to several millimeters, providing greater rigidity, while copper foils are usually under 0.2 mm, offering enhanced flexibility for applications like electronics. Surface finish and conductivity must also be considered; rolled sheets often have a smoother finish useful for architectural uses, whereas copper foil's high conductivity and thin profile suit electromagnetic shielding and flexible circuit boards. Cost and ease of handling influence selection, with rolled sheets being more durable and easier to cut, compared to the delicate and more expensive foils requiring careful installation.

Rolled Copper Sheet vs Copper Foil Infographic

materialdif.com

materialdif.com