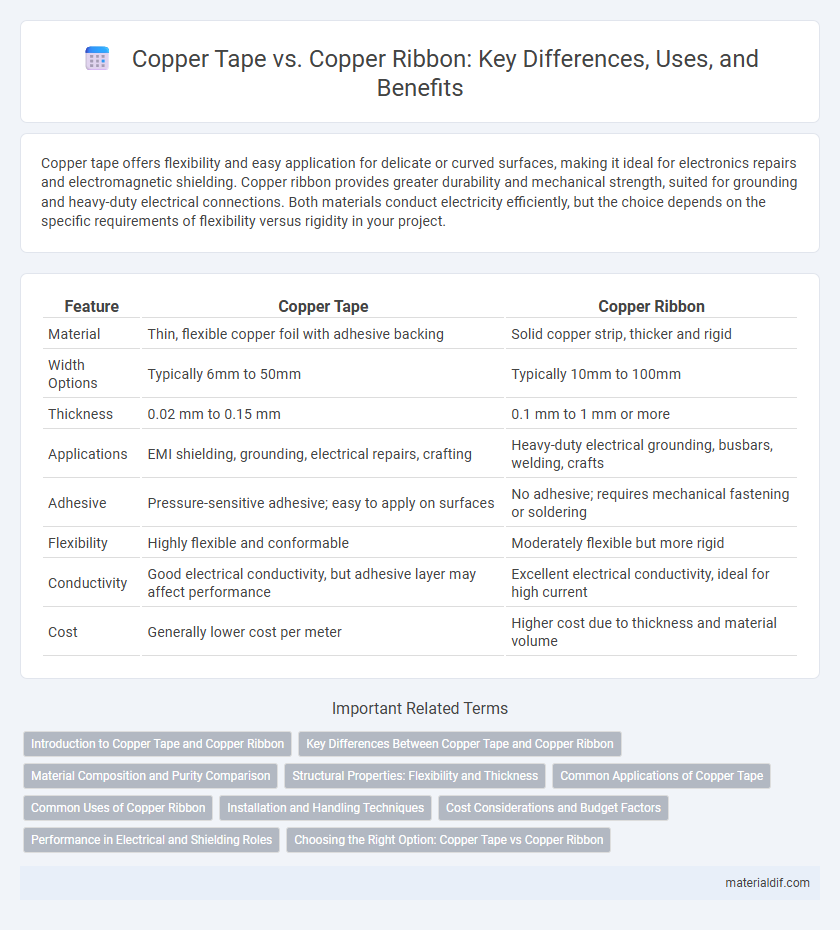

Copper tape offers flexibility and easy application for delicate or curved surfaces, making it ideal for electronics repairs and electromagnetic shielding. Copper ribbon provides greater durability and mechanical strength, suited for grounding and heavy-duty electrical connections. Both materials conduct electricity efficiently, but the choice depends on the specific requirements of flexibility versus rigidity in your project.

Table of Comparison

| Feature | Copper Tape | Copper Ribbon |

|---|---|---|

| Material | Thin, flexible copper foil with adhesive backing | Solid copper strip, thicker and rigid |

| Width Options | Typically 6mm to 50mm | Typically 10mm to 100mm |

| Thickness | 0.02 mm to 0.15 mm | 0.1 mm to 1 mm or more |

| Applications | EMI shielding, grounding, electrical repairs, crafting | Heavy-duty electrical grounding, busbars, welding, crafts |

| Adhesive | Pressure-sensitive adhesive; easy to apply on surfaces | No adhesive; requires mechanical fastening or soldering |

| Flexibility | Highly flexible and conformable | Moderately flexible but more rigid |

| Conductivity | Good electrical conductivity, but adhesive layer may affect performance | Excellent electrical conductivity, ideal for high current |

| Cost | Generally lower cost per meter | Higher cost due to thickness and material volume |

Introduction to Copper Tape and Copper Ribbon

Copper tape and copper ribbon are both versatile materials used in electrical and crafting applications, offering excellent conductivity and flexibility. Copper tape typically features an adhesive backing, making it ideal for precise placement in electronics, electromagnetic shielding, and grounding. Copper ribbon, often thicker and more rigid, is preferred for high-current electrical connections, busbars, and heavy-duty grounding tasks due to its superior conductivity and mechanical strength.

Key Differences Between Copper Tape and Copper Ribbon

Copper tape features a thin, adhesive-backed design ideal for electrical shielding, grounding, and small-scale crafting, while copper ribbon is thicker and lacks adhesive, providing greater durability and conductivity for heavy-duty industrial applications. Copper tape typically measures between 3mm to 50mm in width and is flexible for easy application on irregular surfaces, whereas copper ribbon offers higher tensile strength and is commonly available in wider gauges for structural or heat dissipation uses. The choice between copper tape and copper ribbon hinges on factors such as surface adhesion needs, electrical conductivity requirements, and mechanical robustness.

Material Composition and Purity Comparison

Copper tape typically consists of high-purity electrolytic tough pitch (ETP) copper with a thin adhesive backing, ensuring excellent conductivity and flexibility for electronic and shielding applications. Copper ribbon, often produced from oxygen-free high conductivity (OFHC) copper, offers superior purity and conductivity, making it ideal for electrical wiring and grounding systems requiring minimal resistance and enhanced durability. The difference in material composition reflects their intended use: copper tape balances conductivity with ease of application, while copper ribbon emphasizes maximum purity and performance in demanding electrical environments.

Structural Properties: Flexibility and Thickness

Copper tape exhibits greater flexibility and thinner gauge compared to copper ribbon, making it ideal for applications requiring easy bending and conforming to irregular surfaces. Copper ribbon typically has increased thickness and rigidity, providing enhanced durability and improved electrical conductivity for structural grounding and heavy-duty electromagnetic shielding. Selecting between copper tape and copper ribbon depends on the specific flexibility requirements and mechanical strength needed in the application.

Common Applications of Copper Tape

Copper tape is widely used in electrical applications such as EMI/RFI shielding and grounding due to its excellent conductivity and flexibility. It also serves as a key material in DIY electronics, supporting circuit repairs and antenna construction. Additionally, copper tape is popular in gardening to deter slugs and snails without harmful chemicals.

Common Uses of Copper Ribbon

Copper ribbon is commonly used in electrical grounding and electromagnetic shielding applications due to its excellent conductivity and flexibility. It is often preferred in electronic circuits, transformers, and inductors where effective current distribution and heat dissipation are critical. Its durability and ease of installation make it ideal for use in construction grounding systems and lightning protection.

Installation and Handling Techniques

Copper tape offers flexible application on curved or uneven surfaces due to its thin, adhesive-backed design, allowing easy cutting and direct placement without additional tools. Copper ribbon, thicker and more rigid, requires precise measuring, cutting with shears, and secure fastening, making it ideal for structural grounding or shielding but less adaptable to tight spaces. Both materials demand careful handling to avoid kinks or bends that can compromise electrical conductivity and overall performance.

Cost Considerations and Budget Factors

Copper tape generally offers a more cost-effective solution compared to copper ribbon, especially for smaller projects requiring flexibility and ease of application. Copper ribbons, while sometimes pricier due to their thickness and rigid structure, provide enhanced durability and conductivity for heavy-duty electrical uses. Budget considerations should weigh the project's scale and performance needs, with copper tape preferred for affordable, lightweight tasks and copper ribbon chosen for long-term, high-load applications.

Performance in Electrical and Shielding Roles

Copper tape offers superior flexibility and ease of application, making it ideal for intricate electrical circuits and EMI/RFI shielding in tight spaces. Copper ribbon provides enhanced current-carrying capacity and greater mechanical strength, benefiting power distribution and grounding applications. Performance differences largely depend on thickness, conductivity, and adhesive quality tailored to specific electrical and shielding requirements.

Choosing the Right Option: Copper Tape vs Copper Ribbon

Copper tape offers flexibility and ease of application for intricate surfaces and electrical shielding, making it ideal for DIY electronics and EMI/RFI protection. Copper ribbon, with its thicker gauge and superior conductivity, suits heavy-duty electrical grounding and industrial applications requiring robust current carrying capacity. Selecting between copper tape and ribbon depends on the specific requirements of conductivity, mechanical strength, and installation environment.

Copper Tape vs Copper Ribbon Infographic

materialdif.com

materialdif.com