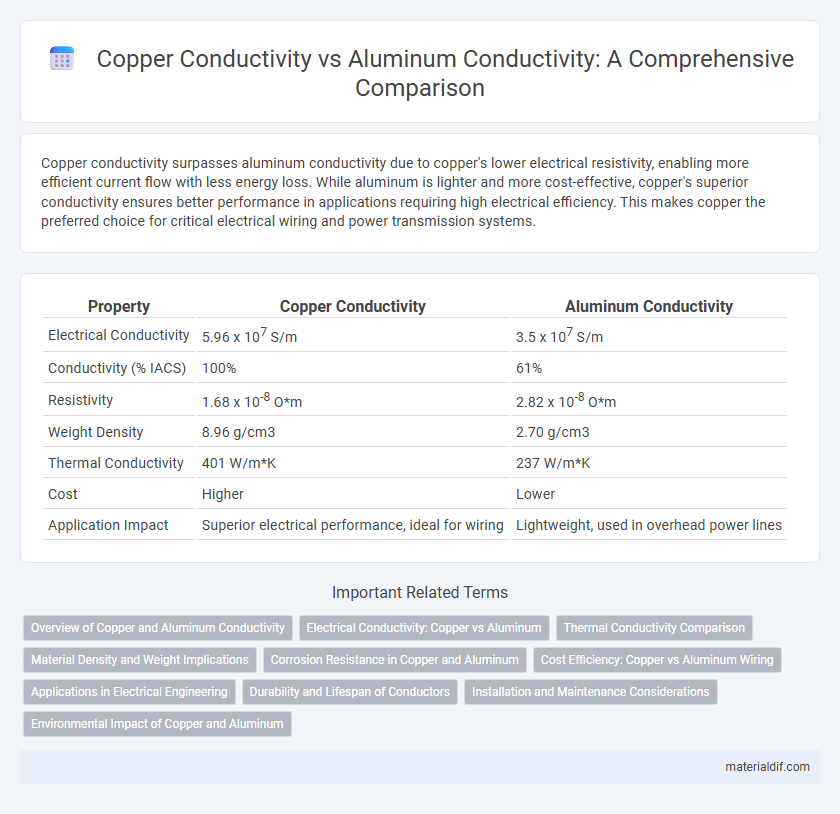

Copper conductivity surpasses aluminum conductivity due to copper's lower electrical resistivity, enabling more efficient current flow with less energy loss. While aluminum is lighter and more cost-effective, copper's superior conductivity ensures better performance in applications requiring high electrical efficiency. This makes copper the preferred choice for critical electrical wiring and power transmission systems.

Table of Comparison

| Property | Copper Conductivity | Aluminum Conductivity |

|---|---|---|

| Electrical Conductivity | 5.96 x 107 S/m | 3.5 x 107 S/m |

| Conductivity (% IACS) | 100% | 61% |

| Resistivity | 1.68 x 10-8 O*m | 2.82 x 10-8 O*m |

| Weight Density | 8.96 g/cm3 | 2.70 g/cm3 |

| Thermal Conductivity | 401 W/m*K | 237 W/m*K |

| Cost | Higher | Lower |

| Application Impact | Superior electrical performance, ideal for wiring | Lightweight, used in overhead power lines |

Overview of Copper and Aluminum Conductivity

Copper exhibits an electrical conductivity of approximately 5.96 x 10^7 S/m, making it one of the most efficient conductors widely used in electrical wiring and electronics. Aluminum's conductivity is about 3.5 x 10^7 S/m, roughly 60% that of copper, but its lower density provides a favorable strength-to-weight ratio for power transmission lines. The superior conductivity and thermal performance of copper often justify its higher cost in critical applications, whereas aluminum is preferred for large-scale, weight-sensitive infrastructure due to cost-effectiveness and corrosion resistance.

Electrical Conductivity: Copper vs Aluminum

Copper exhibits an electrical conductivity of approximately 5.96 x 10^7 S/m, significantly higher than aluminum's 3.5 x 10^7 S/m, making copper a superior conductor for efficient electrical transmission. Despite aluminum's lower conductivity, its lighter weight and lower cost present practical advantages in overhead power lines and large-scale distribution systems. The higher conductivity of copper translates to reduced energy losses and smaller conductor sizes, optimizing performance in critical electrical applications.

Thermal Conductivity Comparison

Copper exhibits significantly higher thermal conductivity than aluminum, making it more efficient for heat transfer applications. Copper's thermal conductivity is approximately 401 W/m*K, while aluminum's is around 237 W/m*K, indicating copper conducts heat nearly 70% better. This superior thermal conductivity positions copper as the preferred material for heat exchangers, electrical wiring, and thermal management systems.

Material Density and Weight Implications

Copper's electrical conductivity is approximately 5.96 x 10^7 S/m, significantly higher than aluminum's 3.5 x 10^7 S/m, allowing copper to carry more current with less resistance. However, copper's density of 8.96 g/cm3 is more than three times that of aluminum's 2.70 g/cm3, resulting in heavier wiring when using copper despite its superior conductivity. This weight difference impacts material selection in applications such as aerospace and power transmission, where aluminum's lower density provides a critical advantage in reducing overall system weight.

Corrosion Resistance in Copper and Aluminum

Copper exhibits superior corrosion resistance compared to aluminum, which plays a critical role in maintaining conductivity over time in electrical applications. While aluminum forms a protective oxide layer that slows further corrosion, copper's resistance to oxidation and chemical degradation ensures lower conductivity loss in harsh environments. This robustness makes copper a preferred choice for long-term, reliable conductivity where exposure to moisture and corrosive elements occurs.

Cost Efficiency: Copper vs Aluminum Wiring

Copper offers superior electrical conductivity, approximately 59.6 MS/m, compared to aluminum's 37.7 MS/m, enabling more efficient current flow and reduced energy loss. While aluminum wiring is generally less expensive and lighter, its lower conductivity requires larger gauge cables to match copper's performance, potentially increasing installation and maintenance costs. Evaluating total cost efficiency involves balancing copper's higher upfront price against aluminum's size and durability considerations in electrical wiring applications.

Applications in Electrical Engineering

Copper offers superior electrical conductivity, averaging about 59.6 million siemens per meter (MS/m), compared to aluminum's 37.8 MS/m, making it the preferred choice for high-efficiency electrical wiring and components. Its higher conductivity ensures lower energy losses and improved performance in power transmission lines, transformers, and motors. Aluminum, while lighter and cost-effective, is commonly used in overhead power lines and large-scale electrical infrastructure where weight savings outweigh conductivity efficiency.

Durability and Lifespan of Conductors

Copper conductivity surpasses aluminum conductivity due to copper's lower electrical resistivity, resulting in less heat generation and enhanced durability in conductors. Copper conductors maintain performance over longer lifespans, resisting corrosion and mechanical wear better than aluminum, which oxidizes and weakens over time. This superior durability of copper reduces maintenance frequency and replacement costs, making it the preferred choice for long-term, reliable electrical applications.

Installation and Maintenance Considerations

Copper's electrical conductivity is approximately 59.6 million siemens per meter, significantly higher than aluminum's 36.9 million siemens per meter, which allows for smaller conductor sizes and easier installation in tight spaces. Copper's superior corrosion resistance reduces maintenance needs and extends lifespan, while aluminum's tendency to oxidize requires additional protective measures such as anti-oxidant compounds and frequent inspections. Installation considerations favor copper for its superior mechanical strength and thermal conductivity, minimizing risks of loosening connections and thermal expansion-related failures during long-term use.

Environmental Impact of Copper and Aluminum

Copper exhibits a higher electrical conductivity of about 59.6 million siemens per meter (MS/m) compared to aluminum's 37.7 MS/m, enabling more efficient energy transmission with lower losses. From an environmental perspective, copper mining and refining involve significant habitat disruption and energy consumption, but copper's recyclability rate of over 90% reduces long-term environmental impact. Aluminum production requires more energy and emits higher greenhouse gases, but its lighter weight lowers fuel consumption in transportation applications, balancing its overall environmental footprint against copper.

Copper Conductivity vs Aluminum Conductivity Infographic

materialdif.com

materialdif.com