Pure copper contains a small amount of oxygen and other impurities that can affect its conductivity and durability, while oxygen-free copper is refined to remove oxygen, resulting in higher purity and enhanced electrical performance. Oxygen-free copper is preferred in high-end audio and electronic applications due to its improved signal clarity and reduced oxidation. The choice between pure copper and oxygen-free copper depends on the specific requirements for conductivity, corrosion resistance, and long-term reliability.

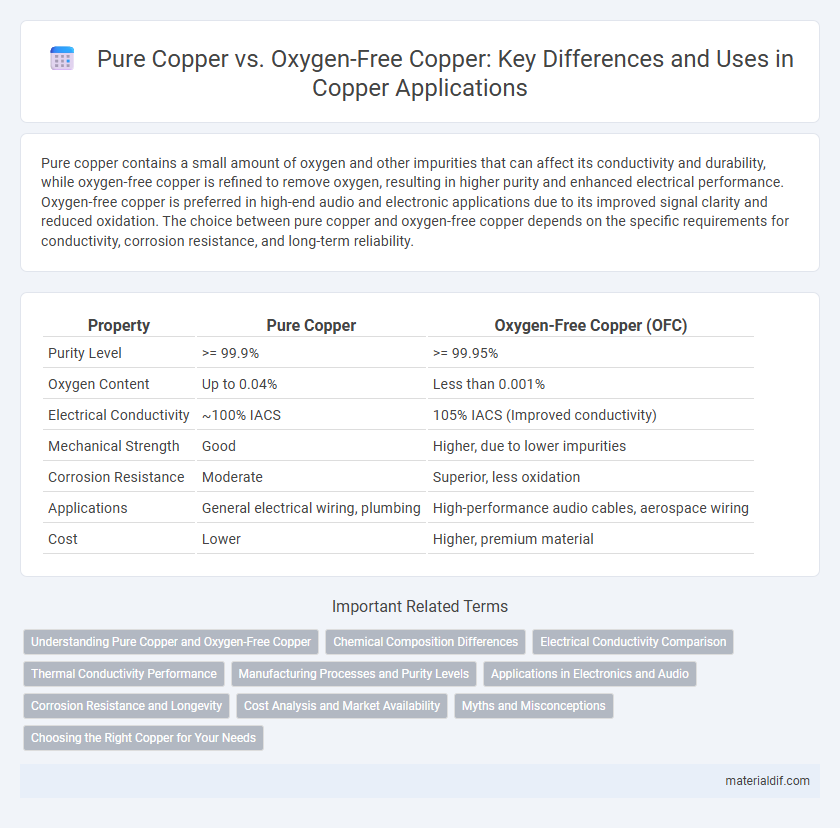

Table of Comparison

| Property | Pure Copper | Oxygen-Free Copper (OFC) |

|---|---|---|

| Purity Level | >= 99.9% | >= 99.95% |

| Oxygen Content | Up to 0.04% | Less than 0.001% |

| Electrical Conductivity | ~100% IACS | 105% IACS (Improved conductivity) |

| Mechanical Strength | Good | Higher, due to lower impurities |

| Corrosion Resistance | Moderate | Superior, less oxidation |

| Applications | General electrical wiring, plumbing | High-performance audio cables, aerospace wiring |

| Cost | Lower | Higher, premium material |

Understanding Pure Copper and Oxygen-Free Copper

Pure copper typically contains trace amounts of oxygen and other impurities, which can affect its electrical conductivity and mechanical properties. Oxygen-free copper, produced in an oxygen-free environment, has a higher purity level with oxygen content below 0.001%, resulting in superior electrical conductivity, enhanced ductility, and improved corrosion resistance. These characteristics make oxygen-free copper ideal for high-performance electrical applications and sensitive electronic components.

Chemical Composition Differences

Pure copper typically contains trace amounts of oxygen and other impurities that can affect its conductivity and durability, while oxygen-free copper (OFC) is refined to contain less than 0.001% oxygen, enhancing its electrical and thermal properties. The reduced oxygen content in OFC minimizes the risk of oxidation and improves mechanical strength, making it ideal for high-performance electrical applications. Chemical composition differences primarily lie in the absence of oxygen and lower impurity levels in OFC, which directly impact its purity and performance in sensitive electronic components.

Electrical Conductivity Comparison

Pure copper typically exhibits electrical conductivity of around 100% IACS (International Annealed Copper Standard), making it highly efficient for electrical applications. Oxygen-free copper, with a purity of 99.95% or higher, is specially refined to reduce oxygen content, enhancing conductivity and reducing the risk of hydrogen embrittlement in critical components. While pure copper remains excellent for general use, oxygen-free copper is preferred in high-performance electronics and audiophile-grade cables due to its superior conductivity and long-term reliability.

Thermal Conductivity Performance

Pure copper exhibits exceptional thermal conductivity, typically around 390 W/m*K, making it an ideal choice for efficient heat dissipation. Oxygen-free copper (OFC) contains minimal oxygen content, which enhances its thermal conductivity by reducing impurities that impede heat transfer, often resulting in slightly higher thermal performance than standard pure copper. These properties make OFC preferred in high-precision electronic applications where maximizing thermal conductivity is critical.

Manufacturing Processes and Purity Levels

Pure copper typically contains trace amounts of oxygen and other impurities, refined through fire or electrolytic refining methods that balance cost and performance. Oxygen-free copper (OFC) undergoes a more stringent manufacturing process involving electrolysis in an oxygen-free environment, achieving purity levels of 99.99% or higher with significantly reduced oxygen content. The enhanced purity and reduced oxygen in OFC improve electrical conductivity and resistance to corrosion, making it ideal for high-performance electrical and audio applications.

Applications in Electronics and Audio

Pure copper, known for its high electrical conductivity, is widely used in general electronics for efficient current flow and corrosion resistance. Oxygen-free copper (OFC) offers enhanced purity with minimal oxygen content, improving signal clarity and reducing oxidation, making it ideal for high-fidelity audio cables and sensitive electronic components. The superior mechanical strength and reduced signal loss of OFC ensure optimal performance in premium audio systems and specialized electronics requiring uncompromised conductivity.

Corrosion Resistance and Longevity

Pure copper contains trace oxygen levels that can form copper oxide, slightly reducing corrosion resistance compared to oxygen-free copper (OFC), which has minimal oxygen content. Oxygen-free copper offers superior corrosion resistance and enhanced longevity due to its higher purity and reduced impurities, making it ideal for high-performance electrical and audio applications. The improved durability of oxygen-free copper ensures longer-lasting conductivity, benefiting environments prone to oxidation and moisture exposure.

Cost Analysis and Market Availability

Pure copper typically offers lower costs due to simpler refining processes, while oxygen-free copper (OFC) commands higher prices because of its enhanced conductivity and reduced oxygen content. Market availability favors pure copper in bulk applications like electrical wiring, whereas oxygen-free copper is more niche, targeted toward audiophile cables and high-performance electronics. Cost differences reflect manufacturing complexity and purity standards, with pure copper dominating mass-market supply chains and OFC appealing to premium segments.

Myths and Misconceptions

Pure copper consists of 99.9% copper with trace impurities, while oxygen-free copper (OFC) has reduced oxygen content to improve conductivity; however, myths claiming OFC significantly outperforms pure copper in electrical applications are exaggerated. The differences in conductivity and signal transmission between pure copper and OFC are minimal and often imperceptible in practical use. Misconceptions arise from marketing claims rather than scientific evidence, as the real-world performance depends more on wire gauge and manufacturing quality than copper purity alone.

Choosing the Right Copper for Your Needs

Pure copper offers excellent electrical conductivity and corrosion resistance, making it ideal for most general electrical applications. Oxygen-free copper, refined to remove oxygen impurities, provides superior thermal and electrical conductivity along with enhanced durability, which is critical in high-performance audio equipment and sensitive electronic components. Selecting the right copper depends on the specific requirements for conductivity, mechanical strength, and environmental resistance in your project.

Pure Copper vs Oxygen-Free Copper Infographic

materialdif.com

materialdif.com