Copper offers superior corrosion resistance compared to galvanized steel, making it ideal for plumbing and roofing applications exposed to harsh environments. While galvanized steel is more cost-effective and provides adequate durability with a protective zinc coating, it is prone to rust once the coating is damaged. Copper also has excellent thermal and electrical conductivity, giving it an advantage in electrical wiring and heat exchange systems where performance and longevity are critical.

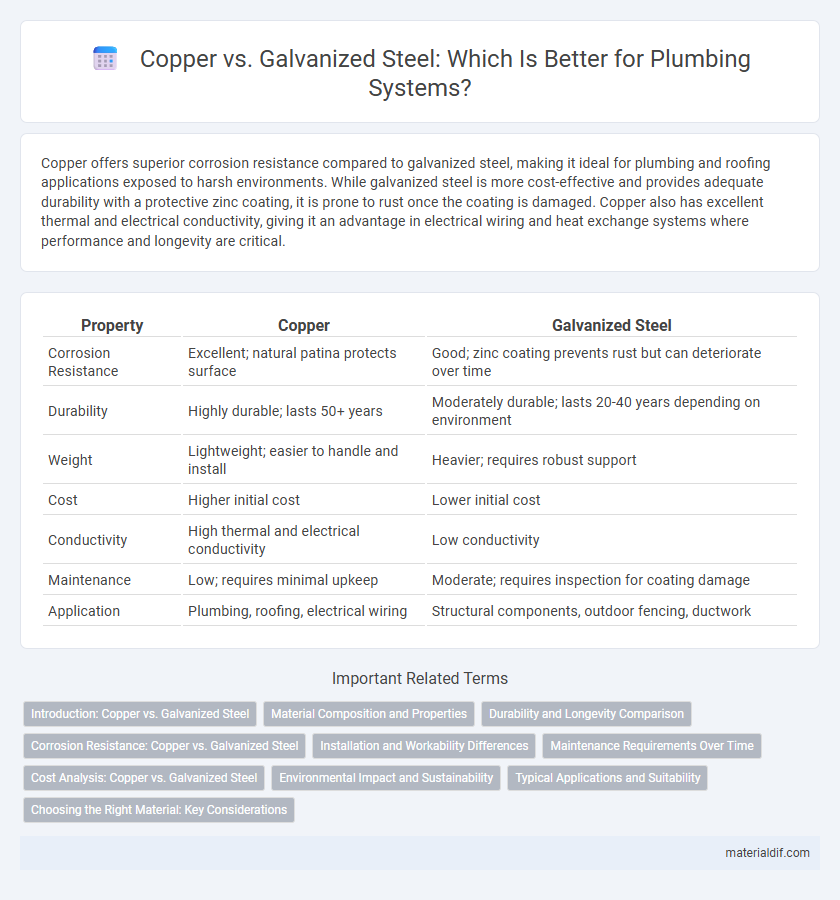

Table of Comparison

| Property | Copper | Galvanized Steel |

|---|---|---|

| Corrosion Resistance | Excellent; natural patina protects surface | Good; zinc coating prevents rust but can deteriorate over time |

| Durability | Highly durable; lasts 50+ years | Moderately durable; lasts 20-40 years depending on environment |

| Weight | Lightweight; easier to handle and install | Heavier; requires robust support |

| Cost | Higher initial cost | Lower initial cost |

| Conductivity | High thermal and electrical conductivity | Low conductivity |

| Maintenance | Low; requires minimal upkeep | Moderate; requires inspection for coating damage |

| Application | Plumbing, roofing, electrical wiring | Structural components, outdoor fencing, ductwork |

Introduction: Copper vs. Galvanized Steel

Copper offers superior corrosion resistance and longevity compared to galvanized steel, making it ideal for plumbing and roofing applications. Galvanized steel provides a cost-effective alternative with a protective zinc coating but is prone to rust over time once the coating wears off. The choice between copper and galvanized steel depends on factors such as budget, environmental exposure, and desired durability.

Material Composition and Properties

Copper consists primarily of pure copper atoms, offering excellent electrical and thermal conductivity along with natural corrosion resistance and antimicrobial properties. Galvanized steel is composed of carbon steel coated with a layer of zinc, which enhances its resistance to rust and corrosion but does not match copper's conductivity or malleability. The zinc coating provides sacrificial protection, whereas copper's inherent properties make it ideal for electrical wiring and plumbing applications requiring durability and longevity.

Durability and Longevity Comparison

Copper offers superior durability and longevity compared to galvanized steel, as it naturally resists corrosion and withstands extreme weather conditions without deteriorating over time. Galvanized steel, coated with a layer of zinc, provides temporary protection but is prone to rust once the coating wears off, leading to reduced lifespan. The inherent antimicrobial properties of copper also contribute to its extended service life in various applications.

Corrosion Resistance: Copper vs. Galvanized Steel

Copper exhibits superior corrosion resistance compared to galvanized steel due to its natural ability to form a protective patina that prevents further oxidation. Galvanized steel relies on a zinc coating that can deteriorate over time, exposing the underlying metal to rust and corrosion. In harsh environments, copper's longevity and low maintenance make it a more durable choice for preventing corrosion-related failures.

Installation and Workability Differences

Copper offers superior malleability and flexibility compared to galvanized steel, making it easier to cut, bend, and fit into complex plumbing configurations. Galvanized steel is rigid and requires specialized tools for cutting and threading, which can prolong installation time and increase labor costs. The corrosion-resistant properties of copper reduce maintenance needs, while galvanized steel may require additional treatment to prevent rust during installation.

Maintenance Requirements Over Time

Copper requires less maintenance over time compared to galvanized steel due to its natural corrosion resistance and ability to develop a protective patina that prevents further degradation. Galvanized steel demands periodic inspections and re-coating to address rust and galvanic corrosion issues that compromise its structural integrity. Consequently, copper offers long-term durability with minimal upkeep, making it a cost-effective choice for maintenance-sensitive applications.

Cost Analysis: Copper vs. Galvanized Steel

Copper generally incurs higher upfront material and installation costs compared to galvanized steel, driven by its superior corrosion resistance and longevity. Galvanized steel offers a more budget-friendly option with lower initial expenses but may require more frequent maintenance and replacement over time, impacting overall lifecycle costs. Evaluating total cost of ownership reveals copper's premium cost is often balanced by reduced maintenance and longer service life in many applications.

Environmental Impact and Sustainability

Copper offers superior environmental benefits over galvanized steel due to its high recyclability and lower carbon footprint during production. Unlike galvanized steel, which requires zinc coating that involves intensive mining and generates hazardous waste, copper can be recycled indefinitely without quality loss, significantly reducing resource depletion. Its natural corrosion resistance also minimizes maintenance and replacement frequency, enhancing long-term sustainability in construction and electrical applications.

Typical Applications and Suitability

Copper offers superior corrosion resistance and excellent electrical conductivity, making it ideal for applications such as electrical wiring, plumbing, and roofing in environments exposed to moisture. Galvanized steel, coated with a layer of zinc, is commonly used in structural components, outdoor fencing, and HVAC ducts due to its affordability and protective oxide layer against rust. Copper is preferred for long-term durability and biostatic properties, while galvanized steel suits budget-conscious projects requiring moderate corrosion protection.

Choosing the Right Material: Key Considerations

Copper offers superior corrosion resistance and excellent conductivity, making it ideal for plumbing and electrical applications where durability and performance are critical. Galvanized steel provides a cost-effective solution with good tensile strength and corrosion resistance through zinc coating, suited for structural and outdoor uses. When choosing between copper and galvanized steel, consider factors such as environmental exposure, budget constraints, maintenance requirements, and the specific demands of the intended application.

Copper vs Galvanized Steel Infographic

materialdif.com

materialdif.com